Intelligent scheduling system and method based on automobile pressure sensor production line

A pressure sensor and intelligent dispatching technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of low production efficiency of manpower dispatching, achieve the effect of automatic configuration, increase response speed, and reduce risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

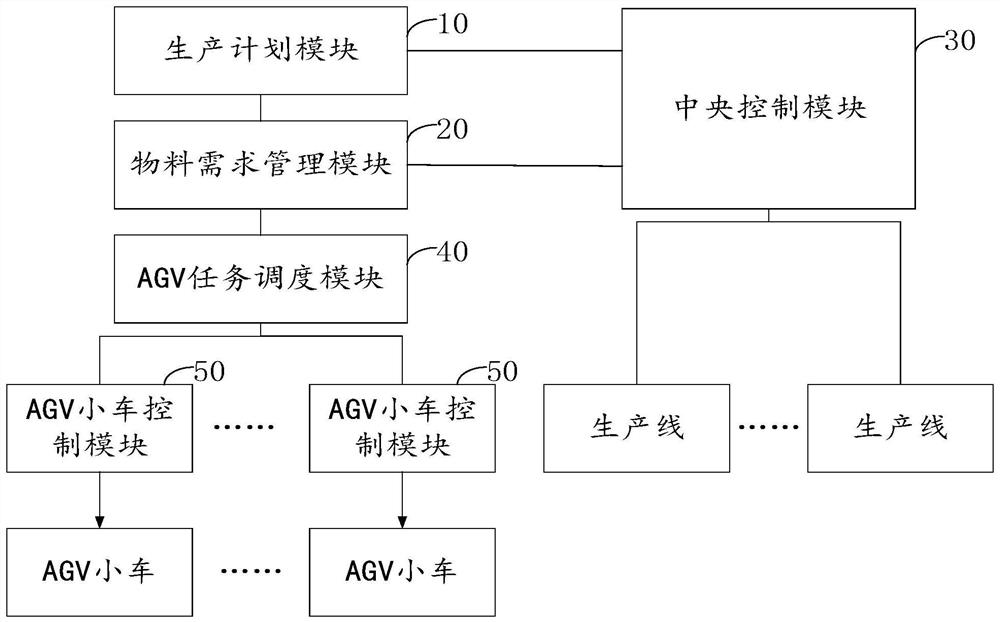

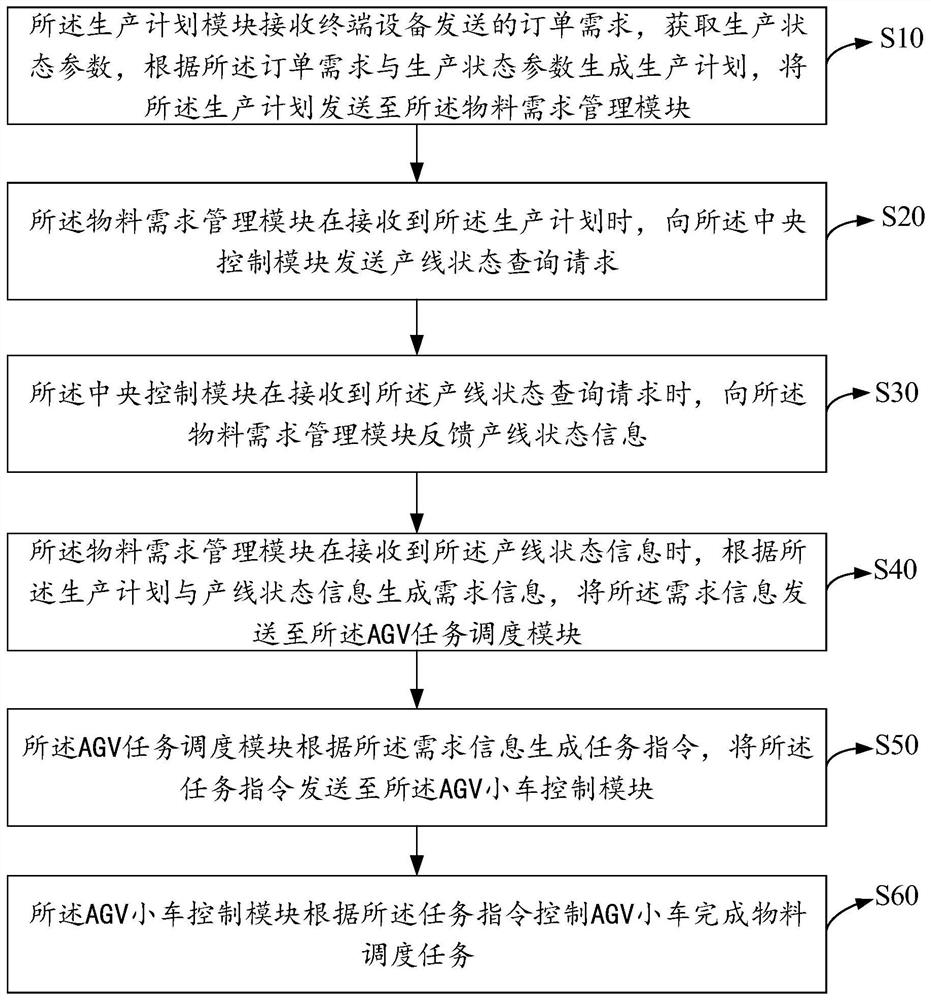

[0051] refer to figure 1 , figure 1 It is a schematic flowchart of the first embodiment of the intelligent scheduling system based on the automobile pressure sensor production line of the present invention.

[0052] The intelligent scheduling system based on the automobile pressure sensor production line includes: a production planning module 10, a material demand management module 20, a central control module 30, an AGV task scheduling module 40 and an AGV trolley control module 50;

[0053] It should be understood that in this embodiment, the production planning module 10, the material demand management module 20, the central control module 30, and the AGV task scheduling module 40 can be connected to each other through a communication bus, and can also interact through wireless communication. This is not limited....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com