Sugarcane harvester and front suspension header root cutting depth control device and method thereof

A technology of depth control and front suspension, which is applied in the direction of harvesters, electric controllers, controllers with specific characteristics, etc., can solve the problem that the quality of sugarcane root cutting cannot be guaranteed stably, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

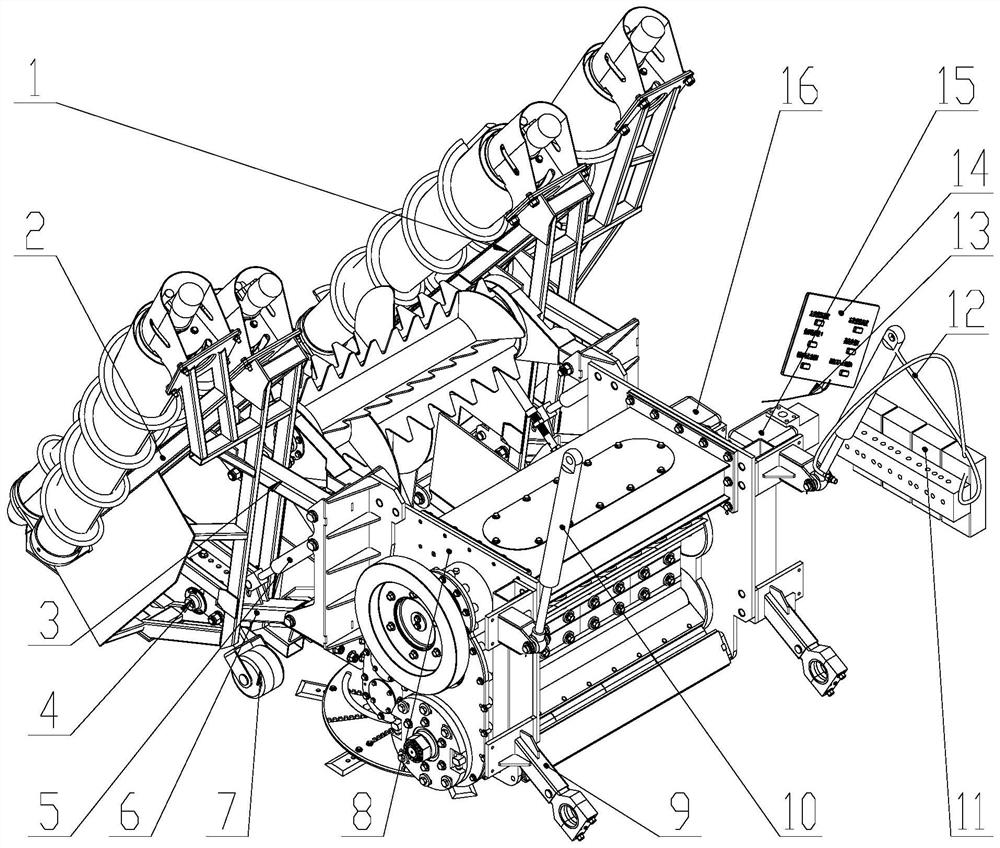

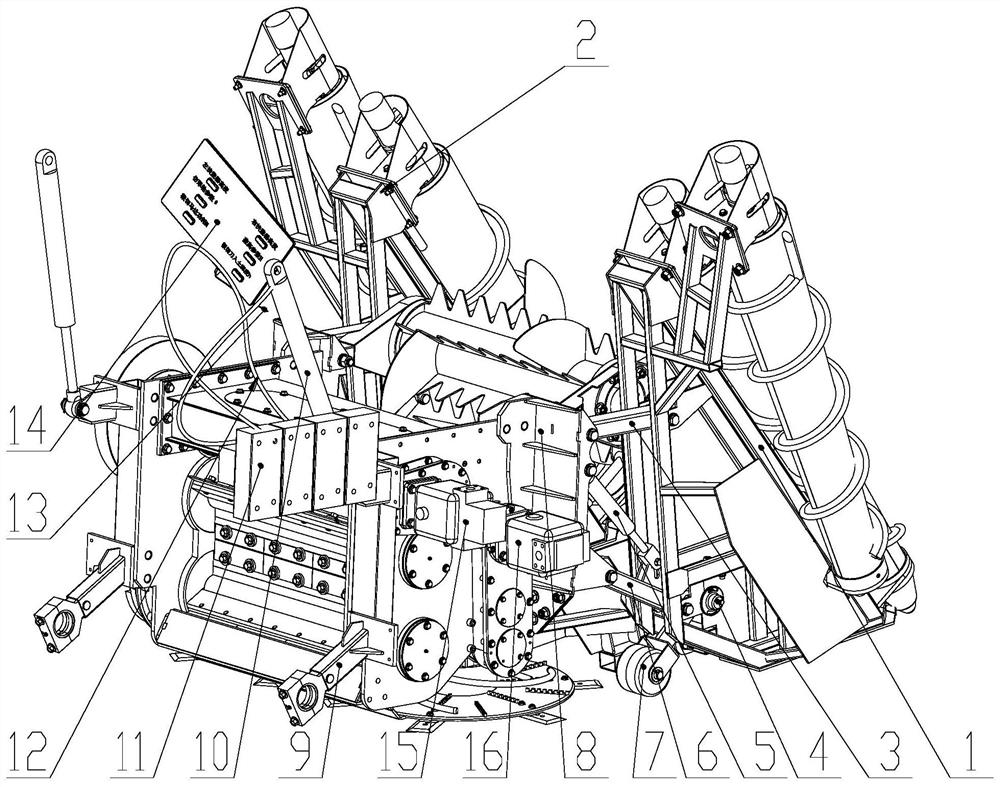

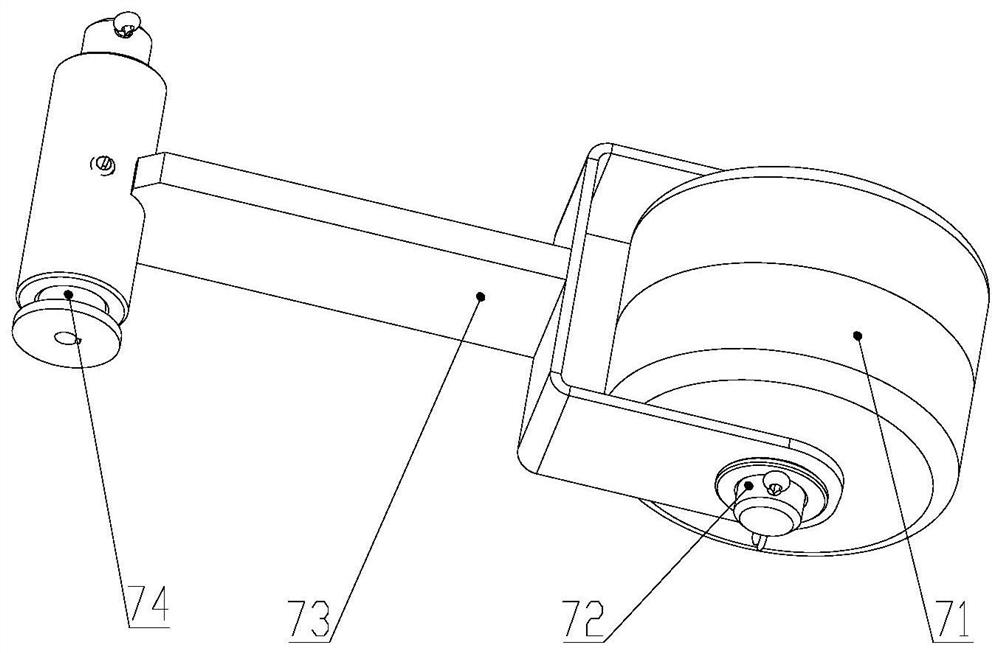

[0060] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0061] The sugarcane harvester of the present invention includes the undercut depth control device of the front suspension header, and adopts the undercut depth control method of the front suspension header to realize the automatic adjustment and control of the undercut depth of the sugarcane, and realizes the accuracy range of the undercut depth during the sugarcane harvesting process. The automatic regulation solves the problem of difficulty in manual control of the undercut depth of existing sugarcane harvesters and large differences, or the low accuracy of power consumption control by using a single undercut motor. The sugarcane undercut depth of the sugarcane harvester has high automatic control accuracy , easy to use, suitable for a variety of terrains, less affected by the human factors of the operator. The composition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com