A collision-resistant additive manufacturing deposition head

An additive manufacturing and anti-collision technology, applied in the field of additive manufacturing, can solve problems such as affecting the deposition process, cumbersome disassembly of components, and jamming, and achieve the effect of avoiding damage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

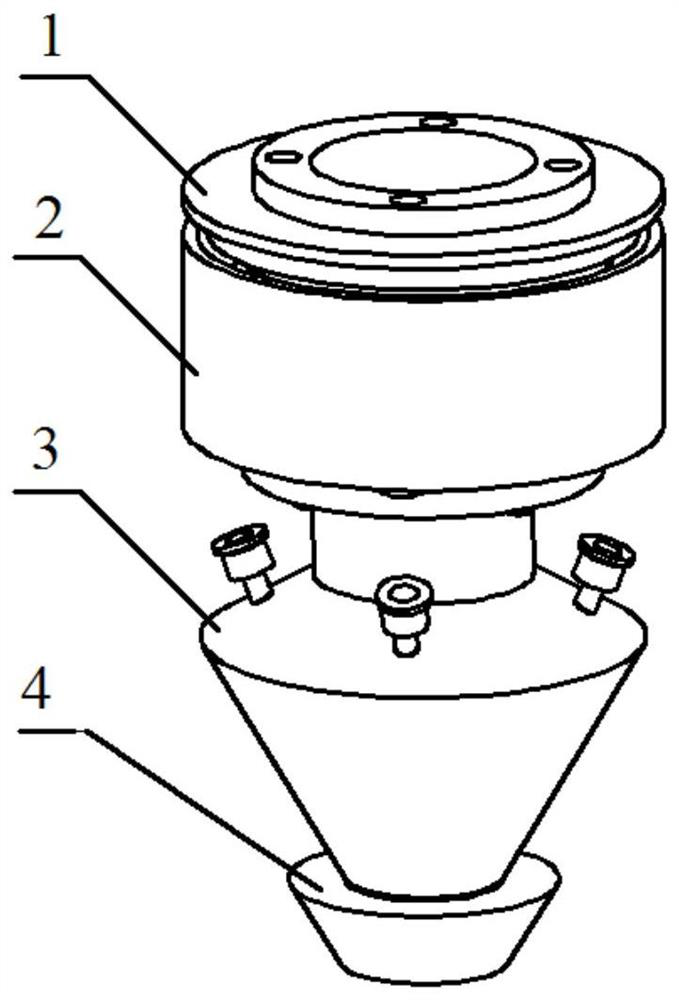

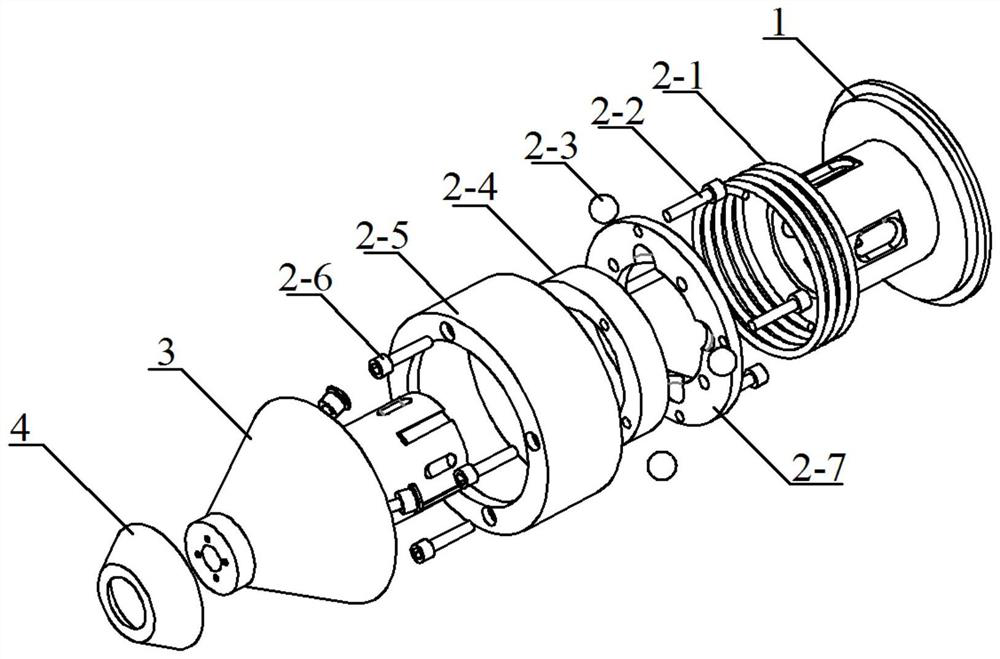

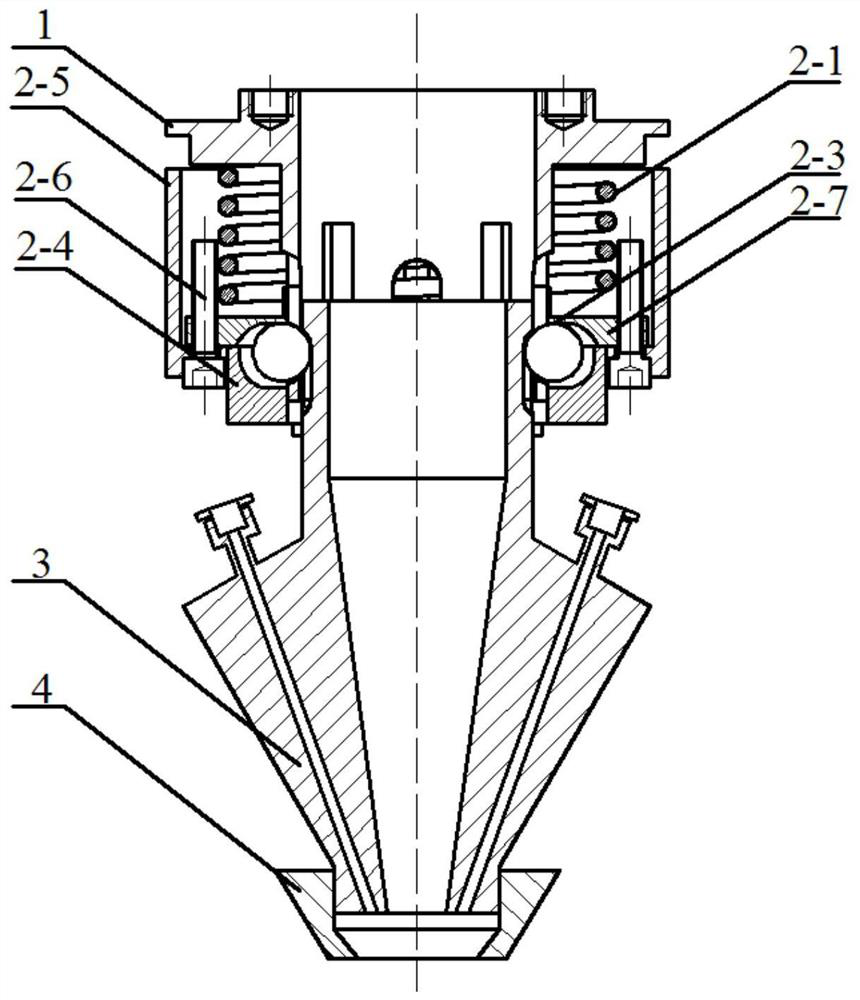

[0037] The present invention is explained in detail by taking laser additive manufacturing with coaxial light powder as an example. Such as figure 2 and image 3 As shown, the upper end of the deposition base 1 is connected with the upper end (without the powder feeding part) of other common laser deposition heads by bolts to ensure that the laser beam can pass through the deposition base.

[0038] The outer diameter of the lower half of the deposition base 1 is 32 mm, and the inner diameter is 28 mm. 4 steps and through grooves are evenly distributed around the lower end, the through grooves are opened on the steps, and the width of the through grooves is 8mm, which allows the rigid balls 2-3 with a diameter of 10mm to only extend into a part of the through grooves.

[0039]The inner diameter of the rigid ball holder 2-7 is the same as the outer diameter of the lower end of the deposition base 1, and the circumference of the inner diameter is provided with four circular gr...

Embodiment 2

[0046] The present invention is explained in detail by taking the TIG arc additive manufacturing of side wire feeding and side blowing shielding gas as an example. Such as Figure 5 , Figure 6 As shown, the upper end of the deposition base 1 is connected to the upper end of other common arc deposition heads by bolts, so as to ensure that the tungsten needle 7 can pass through the deposition base 1 .

[0047] The outer diameter of the lower half of the deposition base 1 is 34 mm, and the inner diameter is 30 mm. There are 3 steps and slots uniformly distributed around the lower end, the slots are opened on the steps, and the width of the slots is 10mm, which allows the rigid balls 2-3 with a diameter of 12mm to only extend into a part of the slots.

[0048] The inner diameter of the rigid ball holder 2-7 is the same as the outer diameter of the lower end of the deposition base 1, and the circumference of the inner diameter is provided with 3 circular grooves that can hold th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com