Reusable UV transfer film and production method thereof

A technology of transfer film and base layer, applied in the field of transfer film, can solve the problems of increased production cost and unreusable UV adhesive layer, and achieves the effect of increasing adhesion and avoiding falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

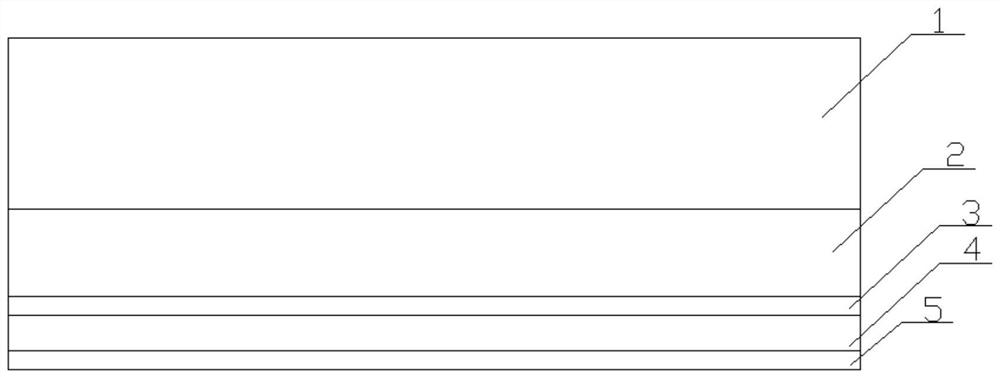

[0031] This embodiment provides a UV transfer film that can be used repeatedly, as attached figure 1 shown. Firstly, the PET is processed to a thickness of 110 μm to obtain a PET base layer 1 , and corona treatment is performed on the PET base layer 1 . Then, gravure printing is used to load the PET base layer 1 with UV ink, and then irradiate with ultraviolet light to cure the UV ink. Different concave-convex microstructures are formed on the PET base layer 1, and the UV imaging information is obtained. Layer 2. The resin was dissolved with acetone and then sprayed onto the UV imaging information layer 2 to obtain a separation layer 3 with a thickness of 50 nm. Aluminum is plated on the surface of the isolation layer 3 to form an aluminum layer 4, and finally a back glue layer 5 of a water-based environmentally friendly thermal transfer adhesive is coated under the aluminum layer 4, thereby obtaining a reusable UV transfer film.

[0032] Since the aluminum layer is thin, t...

Embodiment 2

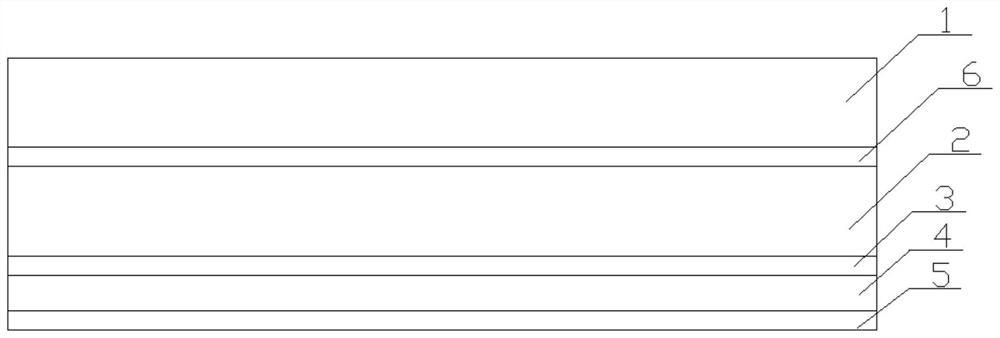

[0035] The difference between this embodiment and embodiment 1 is: as attached figure 2 As shown, (1) PET base layer 1 was obtained by processing PET to 60 μm; (2) hyperbranched polyurethane was sprayed on the lower surface of PET base layer 1 as surface modification layer 6, and then gravure printing was applied on the surface modification layer 6 is coated with UV ink, and then irradiated with ultraviolet light to cure the UV ink to obtain a UV imaging information layer 2. There is strong adhesion between the hyperbranched polyurethane and the PET base layer 1 and the UV imaging information layer 2, so the enhanced (3) dissolving the nano wax with toluene and then spraying it on the UV imaging information layer 2 to obtain a separation layer 3 with a thickness of 30nm.

[0036] This embodiment obtains the UV transfer film. During the thermal transfer process, the isolation layer 3 can be broken smoothly, so that the aluminum layer 4 and the UV imaging information layer 2 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com