A method for preparing micron materials using surfactant-induced self-assembly metalloporphyrin

A technology of surfactants and metalloporphyrins, applied in the direction of luminescent materials, chemical instruments and methods, cobalt organic compounds, etc., can solve the problems of lack of micro-material regulation and unfavorable fine preparation of micro-materials, so as to facilitate loading and dispersion , The synthesis process is simple and feasible, and the structure is novel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Prepare 0.1mM 2mL of SDS;

[0020] 2) Prepare 0.25M 100mL aqueous solution of tetrakis(phenyl-4-sulfonic acid)zinc porphyrin, add it to 1), and preheat to 60°C;

[0021] 3) Prepare 0.25M 100 mL aqueous solution of tetrakis (N-ethanol-4-pyridyl) cobalt porphyrin, preheat to 60° C., add to 2), stir for 5 min, centrifuge, wash with water, and dry to obtain the final product.

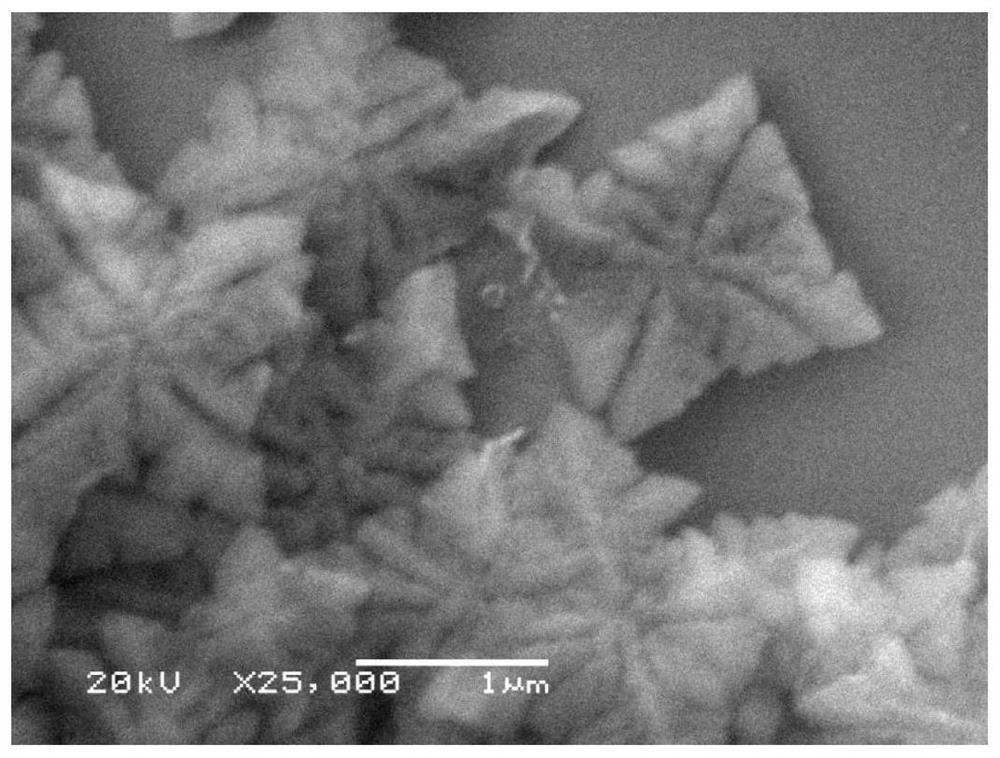

[0022] like figure 1 , the transmission electron microscope image of the final product prepared in Example 1, and its morphology is a snowflake-like structure.

Embodiment 2

[0024] 1) Prepare 0.1mM 2mL of SDS;

[0025] 2) Prepare 0.25M 100mL aqueous solution of tetrakis(phenyl-4-sulfonic acid)zinc porphyrin, add it to 1), and preheat to 60°C;

[0026] 3) Prepare 0.25M 100mL aqueous solution of tetrakis (N-ethanol-4-pyridyl)cobalt porphyrin, prepare 0.1mM 2mL CTAB aqueous solution, mix the two and preheat to 60°C, add to 2), stir for 5min and centrifuge , washed with water, and dried to obtain the final product.

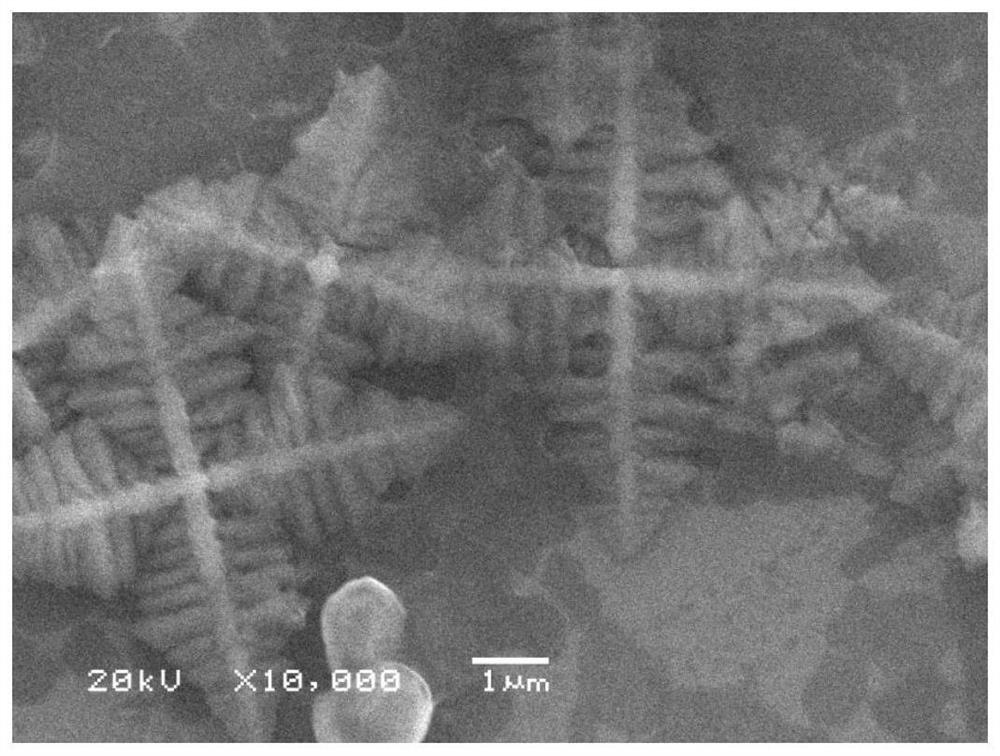

[0027] like figure 2 , the transmission electron microscope image of the final product prepared in Example 1, and its morphology is a snowflake-like structure.

Embodiment 3

[0029] 1) Prepare 4 mM 20 mL of SDS;

[0030] 2) Prepare 0.25M 100mL aqueous solution of tetrakis (phenyl-4-sulfonic acid group) zinc porphyrin, add it to 1), and preheat at 90°C;

[0031] 3) Prepare a 0.25M 100 mL aqueous solution of tetrakis (N-ethanol-4-pyridyl) cobalt porphyrin, preheat at 90° C., add to 2), stir for 40 min, centrifuge, wash with water, and dry to obtain the final product.

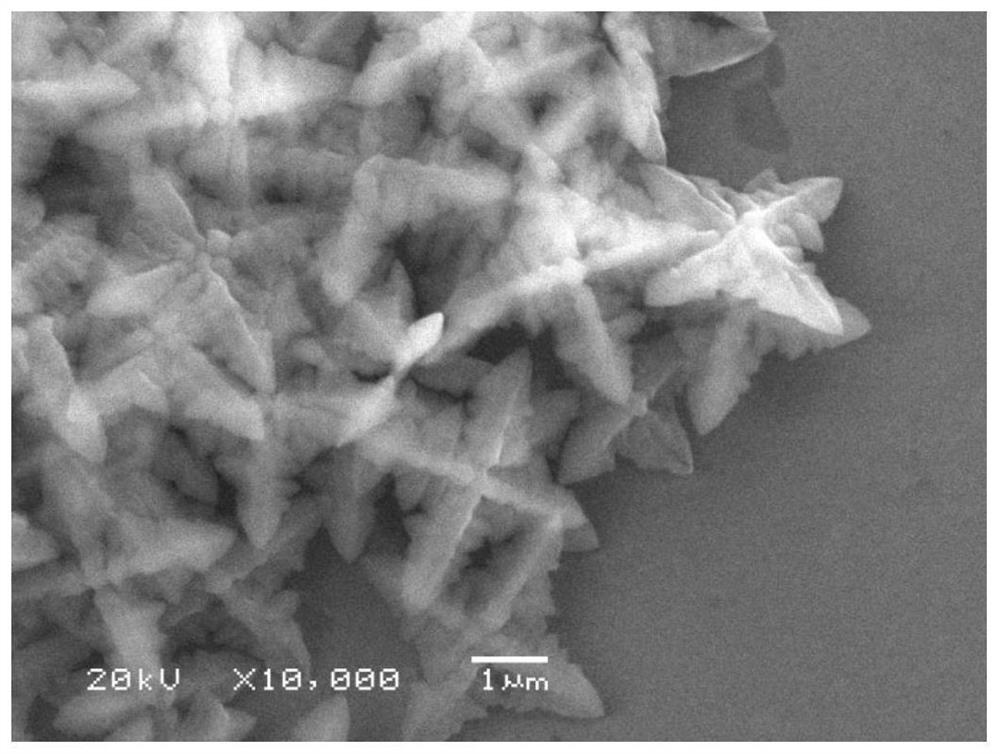

[0032] like image 3 , the transmission electron microscope image of the final product prepared in Example 1, and its morphology is a snowflake-like structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com