A preparation method of ddmbdx-pi/tpu with high transparency and easy processing

A DDMBDX-PI, easy-to-process technology, which is applied in the field of high-transparency and easy-to-process DDMBDX-PI/TPU preparation, can solve the problems that the transparency of thermoplastic polyurethane needs to be improved, so as to increase organic affinity, improve dispersion ability, and good nucleation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

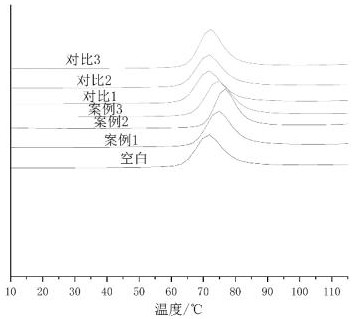

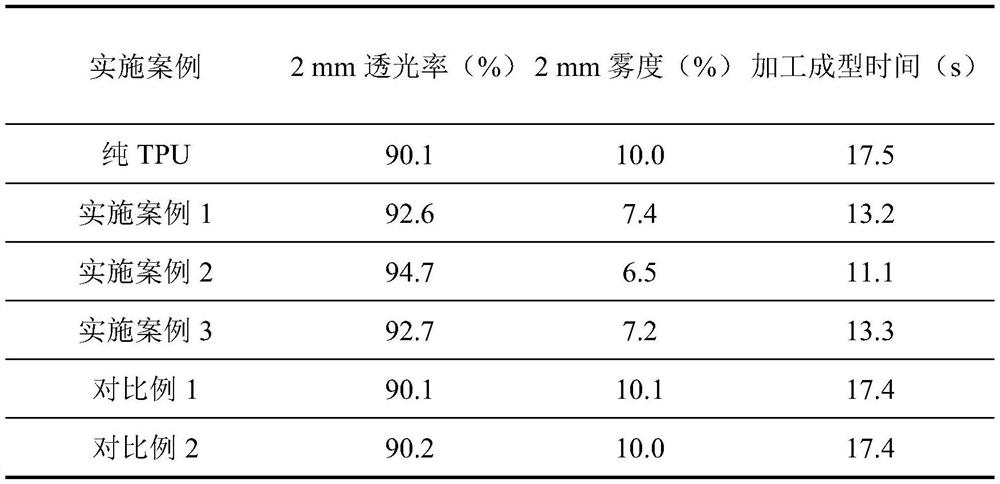

[0031] A preparation method of DDMBDX-PI / TPU with high transparency and easy processing and molding. The raw materials include: 52.75 parts of polytetrahydrofuran, 9.0 parts of 1,4-butanediol, 38.25 parts of diphenylmethane diisocyanate, Nucleating agent DDMBDX-PI0.1 part.

[0032] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0033] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0034] The catalyst is selected from organotin dibutyltin dilaurate.

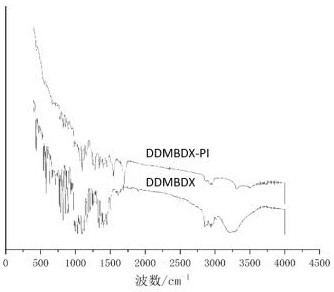

[0035] The preparation of DDMBDX-PI: Pretreatment: Since propyl isocyanate can react with water, if there is water in the reaction system, it will affect the progress of the reaction, so it is necessary to fully remove water before the reaction. Before the reaction, put 10g DDMBDX into a vacuum drying oven to fully dry; put 5-10 fully dried 4A molecular sieves into 20ml of 1-methyl-2-pyrrolidone (NMP) solvent and seal t...

Embodiment 2

[0039] A preparation method of DDMBDX-PI / TPU with high transparency and easy processing and molding. The raw materials include: 52.75 parts of polytetrahydrofuran, 9.0 parts of 1,4-butanediol, 38.25 parts of diphenylmethane diisocyanate, Nucleating agent DDMBDX-PI0.15 parts.

[0040] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0041] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0042] The catalyst is selected from organotin dibutyltin dilaurate.

[0043] The preparation of DDMBDX-PI: Pretreatment: Since propyl isocyanate can react with water, if there is water in the reaction system, it will affect the progress of the reaction, so it is necessary to fully remove water before the reaction. Before the reaction, put 10g DDMBDX into a vacuum drying oven to fully dry; put 5-10 fully dried 4A molecular sieves into 20ml of 1-methyl-2-pyrrolidone (NMP) solvent and seal...

Embodiment 3

[0047] A preparation method of DDMBDX-PI / TPU with high transparency and easy processing and molding. The raw materials include: 52.75 parts of polytetrahydrofuran, 9.0 parts of 1,4-butanediol, 38.25 parts of diphenylmethane diisocyanate, Nucleating agent DDMBDX-PI0.2 parts.

[0048] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0049] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0050] The catalyst is selected from organotin dibutyltin dilaurate.

[0051] The preparation of DDMBDX-PI: Pretreatment: Since propyl isocyanate can react with water, if there is water in the reaction system, it will affect the progress of the reaction, so it is necessary to fully remove water before the reaction. Before the reaction, put 10g DDMBDX into a vacuum drying oven to fully dry; put 5-10 fully dried 4A molecular sieves into 20ml of 1-methyl-2-pyrrolidone (NMP) solvent and seal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com