Preparation method of BI-SiO2/TPU with high transparency and easy processing molding

An easy-to-process, bi-sio2 technology, applied in the field of thermoplastic elastomers, can solve the problems of glass without flexibility and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

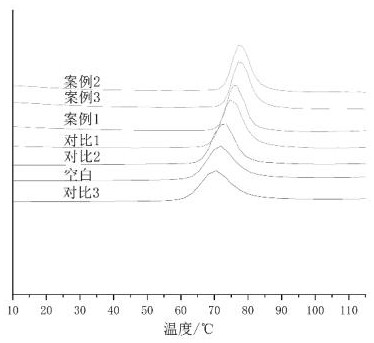

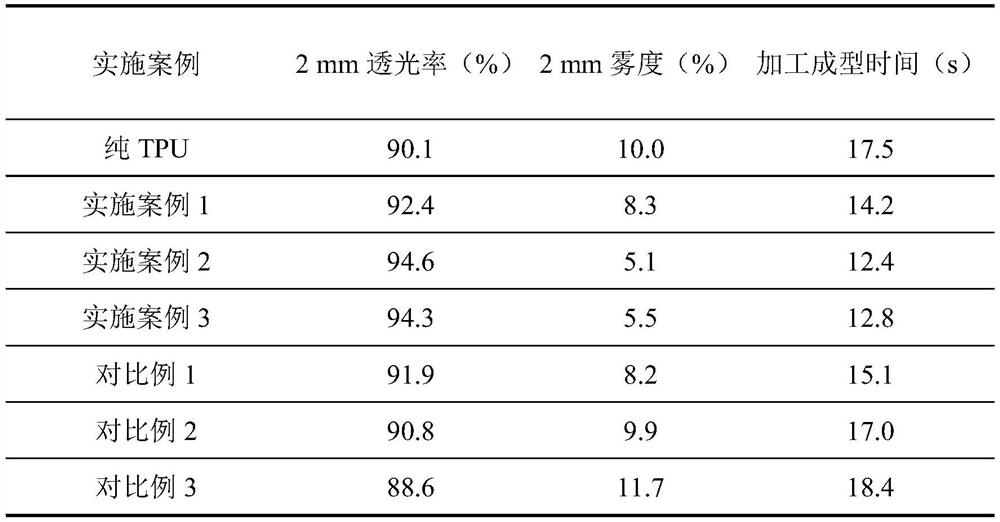

[0036] A kind of BI-SiO with high transparency and easy processing 2 / The preparation method of TPU, its raw material includes by weight: 52.75 parts of polytetrahydrofuran, 9.0 parts of 1,4-butanediol, 38.25 parts of diphenylmethane diisocyanate, nucleating agent BI-SiO 2 0.1 part.

[0037] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0038]The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

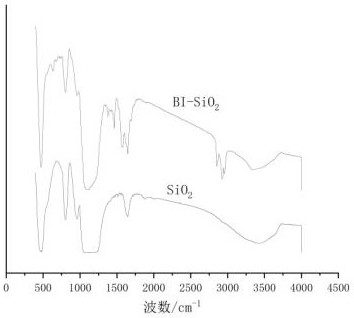

[0039] The BI-SiO 2 Preparation: 5-10 grains of 4A molecular sieves were activated in a vacuum oven at 120°C for 12 hours, and the activated 4A molecular sieves were added with 20ml of N-methylpyrrolidone and sealed for 24 hours to remove the moisture in the N-methylpyrrolidone. Dry 0.5-1.0g of nano silicon dioxide in a vacuum oven at 120°C for 5 hours to remove the moisture adsorbed on the surface and obtain activated SiO 2 . At room temperature, weigh 0.5g of baked nano-sili...

Embodiment 2

[0047] A kind of BI-SiO with high transparency and easy processing 2 / The preparation method of TPU, its raw material includes by weight: 52.75 parts of polytetrahydrofuran, 9.0 parts of 1,4-butanediol, 38.25 parts of diphenylmethane diisocyanate, nucleating agent BI-SiO 2 0.2 parts.

[0048] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0049] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0050] The BI-SiO 2 Preparation: 5-10 grains of 4A molecular sieves were activated in a vacuum oven at 120°C for 12 hours, and the activated 4A molecular sieves were added with 20ml of N-methylpyrrolidone and sealed for 24 hours to remove the moisture in the N-methylpyrrolidone. Dry 0.5-1.0g of nano silicon dioxide in a vacuum oven at 120°C for 5 hours to remove the moisture adsorbed on the surface and obtain activated SiO 2 . At room temperature, weigh 0.5g of baked nano-si...

Embodiment 3

[0058] A kind of BI-SiO with high transparency and easy processing 2 / The preparation method of TPU, its raw material includes by weight: 52.75 parts of polytetrahydrofuran, 9.0 parts of 1,4-butanediol, 38.25 parts of diphenylmethane diisocyanate, nucleating agent BI-SiO 2 0.3 parts.

[0059] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0060] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0061] The BI-SiO 2 Preparation: 5-10 grains of 4A molecular sieves were activated in a vacuum oven at 120°C for 12 hours, and the activated 4A molecular sieves were added with 20ml of N-methylpyrrolidone and sealed for 24 hours to remove the moisture in the N-methylpyrrolidone. Dry 0.5-1.0g of nano silicon dioxide in a vacuum oven at 120°C for 5 hours to remove the moisture adsorbed on the surface and obtain activated SiO 2 . At room temperature, weigh 0.5g of baked nano-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com