A highly transparent and easy-to-process bi-sio 2 /tpu preparation method

An easy-to-process, bi-sio2 technology, applied in the field of thermoplastic elastomers, can solve the problems of limited application scope and lack of flexibility of glass, and achieve the effect of improving steric hindrance and preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

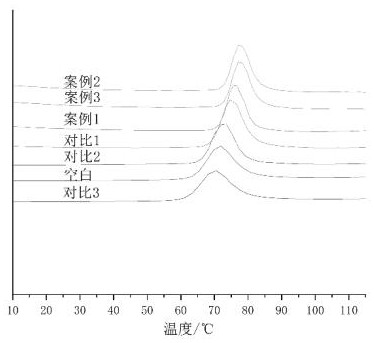

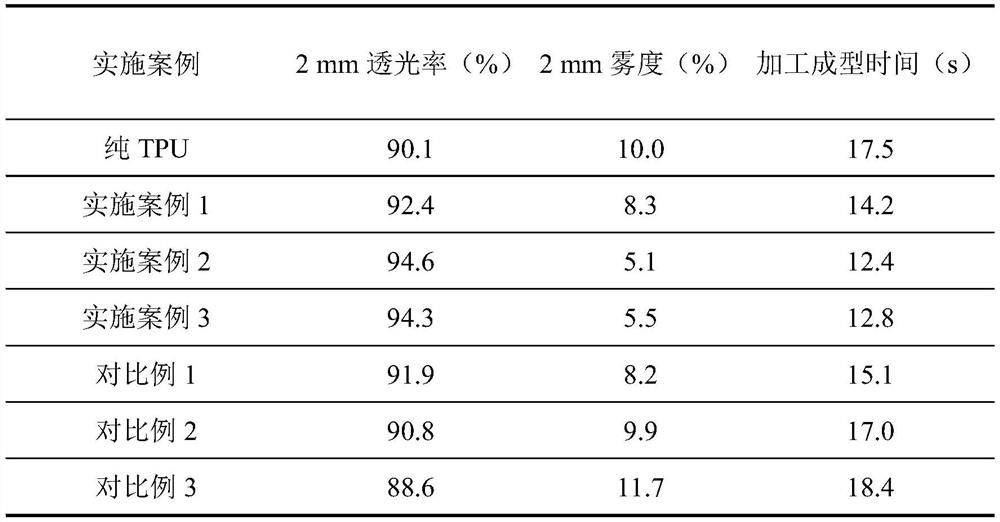

[0036] A highly transparent BI-SiO that is easy to process and mold 2 Preparation method of / TPU, the raw materials in terms of the number of parts by weight include: polytetrahydrofuran 52.75 parts, 1,4-butanediol 9.0 parts, diphenylmethane diisocyanate 38.25 parts, nucleating agent BI-SiO 2 0.1 serving.

[0037] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0038] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12, a hydroxyl value of 1000 ~ 1200mg KOH / g.

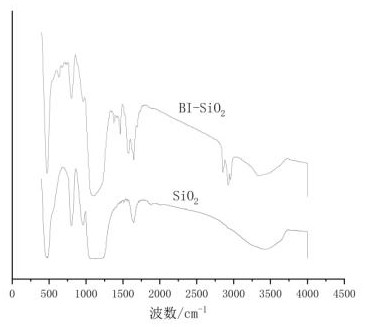

[0039] The BI-SiO 2 Preparation: 5-10 4A type molecular sieves were placed in a vacuum oven at 120 °C for 12 h, and the activated 4A type molecular sieves were added to the 20 ml N-methylpyrrolidone sealed for 24 h to remove the moisture in N-methylpyrrolidone. 0.5-1.0g nano silica was baked at 120 °C in a vacuum oven for 5 h to remove the moisture adsorbed on the surface to obtain activated SiO 2 。 At room temperature, the baked nano-silica weighed 0.5g dispers...

Embodiment 2

[0047] A highly transparent BI-SiO that is easy to process and mold 2 Preparation method of / TPU, the raw materials in terms of the number of parts by weight include: polytetrahydrofuran 52.75 parts, 1,4-butanediol 9.0 parts, diphenylmethane diisocyanate 38.25 parts, nucleating agent BI-SiO 2 0.2 servings.

[0048] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0049]The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12, a hydroxyl value of 1000 ~ 1200mg KOH / g.

[0050] The BI-SiO 2 Preparation: 5-10 4A type molecular sieves were placed in a vacuum oven at 120 °C for 12 h, and the activated 4A type molecular sieves were added to the 20 ml N-methylpyrrolidone sealed for 24 h to remove the moisture in N-methylpyrrolidone. 0.5-1.0g nano silica was baked at 120 °C in a vacuum oven for 5 h to remove the moisture adsorbed on the surface to obtain activated SiO 2 。 At room temperature, the baked nano-silica weighed 0.5g disper...

Embodiment 3

[0058] A highly transparent BI-SiO that is easy to process and mold 2 Preparation method of / TPU, the raw materials in terms of the number of parts by weight include: polytetrahydrofuran 52.75 parts, 1,4-butanediol 9.0 parts, diphenylmethane diisocyanate 38.25 parts, nucleating agent BI-SiO 2 0.3 servings.

[0059] The molecular weight of the polytetrahydrofuran is between 1024-1056.

[0060] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12, a hydroxyl value of 1000 ~ 1200mg KOH / g.

[0061] The BI-SiO 2 Preparation: 5-10 4A type molecular sieves were placed in a vacuum oven at 120 °C for 12 h, and the activated 4A type molecular sieves were added to the 20 ml N-methylpyrrolidone sealed for 24 h to remove the moisture in N-methylpyrrolidone. 0.5-1.0g nano silica was baked at 120 °C in a vacuum oven for 5 h to remove the moisture adsorbed on the surface to obtain activated SiO 2 。 At room temperature, the baked nano-silica weighed 0.5g disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com