A kind of high wear-resistant matte feel oil and its preparation method and application method

An application method, the technology of hand oil, which is applied in the field of hand oil, can solve the problems of affecting product appearance, poor visual effect, poor wear resistance, etc., and achieve the effect of ensuring smooth texture, improving wear resistance, and increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

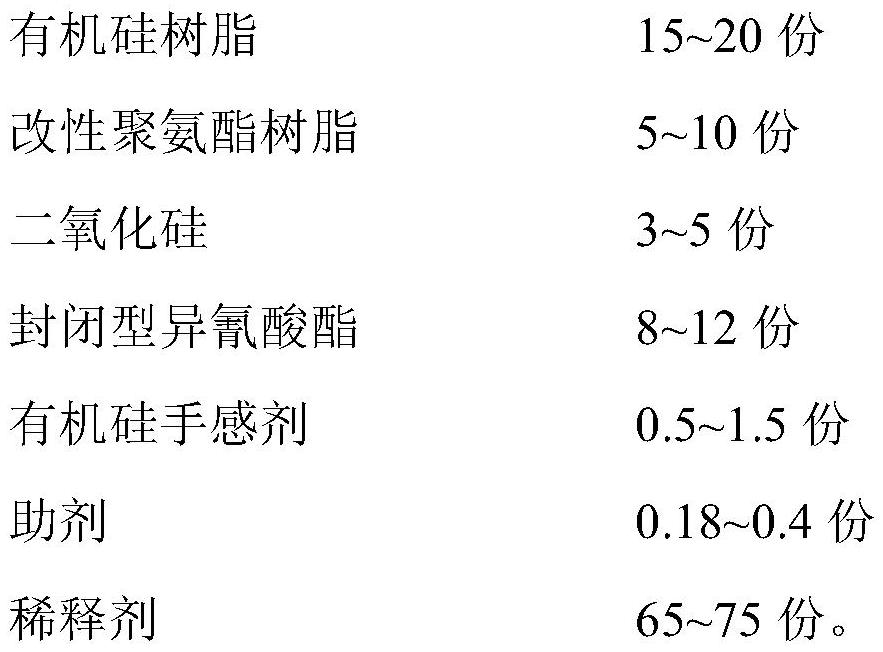

[0030] A high wear-resistant matte feel oil, comprising the following raw materials in parts by weight:

[0031]

[0032] In this embodiment, the diluent is an ester organic solvent and / or an alcohol organic solvent.

[0033] In this embodiment, the additives include 0.1 part of silicone leveling agent, 0.1 part of silicone defoamer and 0.1 part of silicone dispersant.

[0034] The preparation method of the above-mentioned high wear-resistant matte feel oil includes the following steps executed in sequence:

[0035] A mixing step, which is used to add the silicone resin, modified polyurethane resin, blocked isocyanate, silicone hand feeling agent and additives into the container and mix and stir for 3 minutes at a speed of 1200 rpm to obtain a mixed material;

[0036] A dispersion step, which is used to add a formula amount of silicon dioxide to the mixed material obtained in the mixing step, and mix and stir at a speed of 1200 rpm for 30 minutes to obtain a high-viscosity...

Embodiment 2

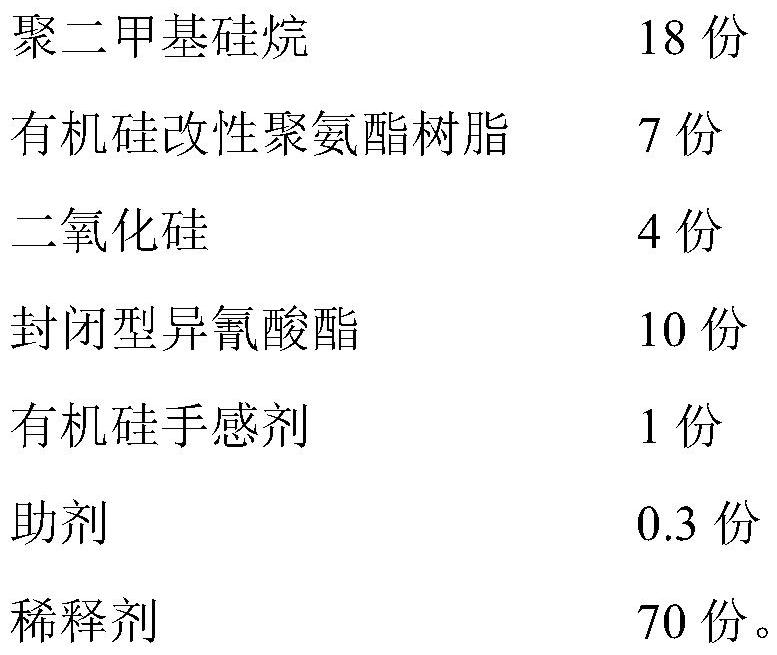

[0043] A high wear-resistant matte feel oil, comprising the following raw materials in parts by weight:

[0044]

[0045] In this embodiment, the diluent is an ester organic solvent and / or an alcohol organic solvent.

[0046] In this embodiment, the additives include 0.05 part of silicone leveling agent, 0.07 part of silicone defoamer and 0.06 part of silicone dispersant.

[0047] The preparation method of the above-mentioned high wear-resistant matte feel oil includes the following steps executed in sequence:

[0048] A mixing step, which is used to add the silicone resin, modified polyurethane resin, blocked isocyanate, silicone hand feeling agent and additives into the container and mix and stir for 4 minutes at a speed of 1000 rpm to obtain a mixed material;

[0049] A dispersion step, which is used to add a formula amount of silicon dioxide to the mixed material obtained in the mixing step, and mix and stir at a speed of 1000 rpm for 35 minutes to obtain a high-viscos...

Embodiment 3

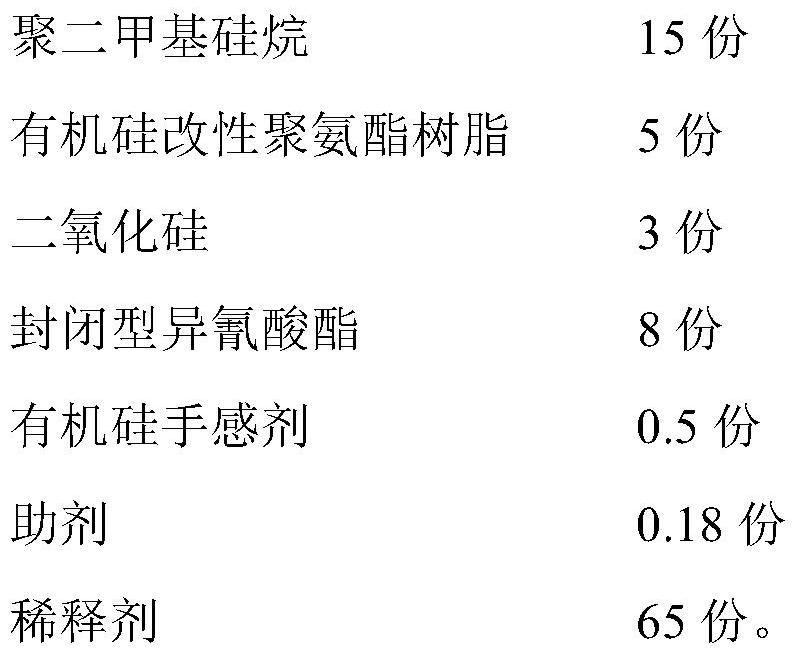

[0056] A high wear-resistant matte feel oil, comprising the following raw materials in parts by weight:

[0057]

[0058]

[0059] In this embodiment, the diluent is an ester organic solvent and / or an alcohol organic solvent.

[0060] In this embodiment, the additives include 0.15 parts of silicone leveling agent, 0.13 parts of silicone defoamer and 0.12 parts of silicone dispersant.

[0061] The preparation method of the above-mentioned high wear-resistant matte feel oil includes the following steps executed in sequence:

[0062]A mixing step, which is used to add the silicone resin, modified polyurethane resin, blocked isocyanate, silicone hand feeling agent and additives into the container and mix and stir for 2 minutes at a speed of 1500 rpm to obtain a mixed material;

[0063] A dispersion step, which is used to add a formula amount of silicon dioxide to the mixed material obtained in the mixing step, and mix and stir at a speed of 1500 rpm for 25 minutes to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com