Desulfurization and denitrification tower and desulfurization and denitrification method

A desulfurization, denitrification and denitration technology, which is applied in the field of gas desulfurization and denitrification and desulfurization and denitrification, can solve the problems of sulfur poisoning and reduction of removal efficiency, and achieve the effects of increasing the contact area, increasing the reaction time, and improving the reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

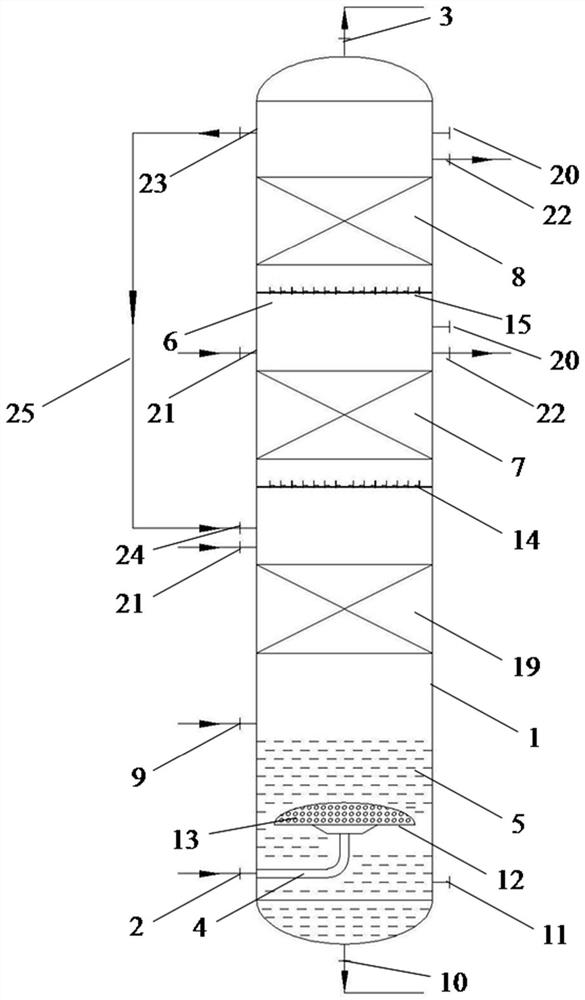

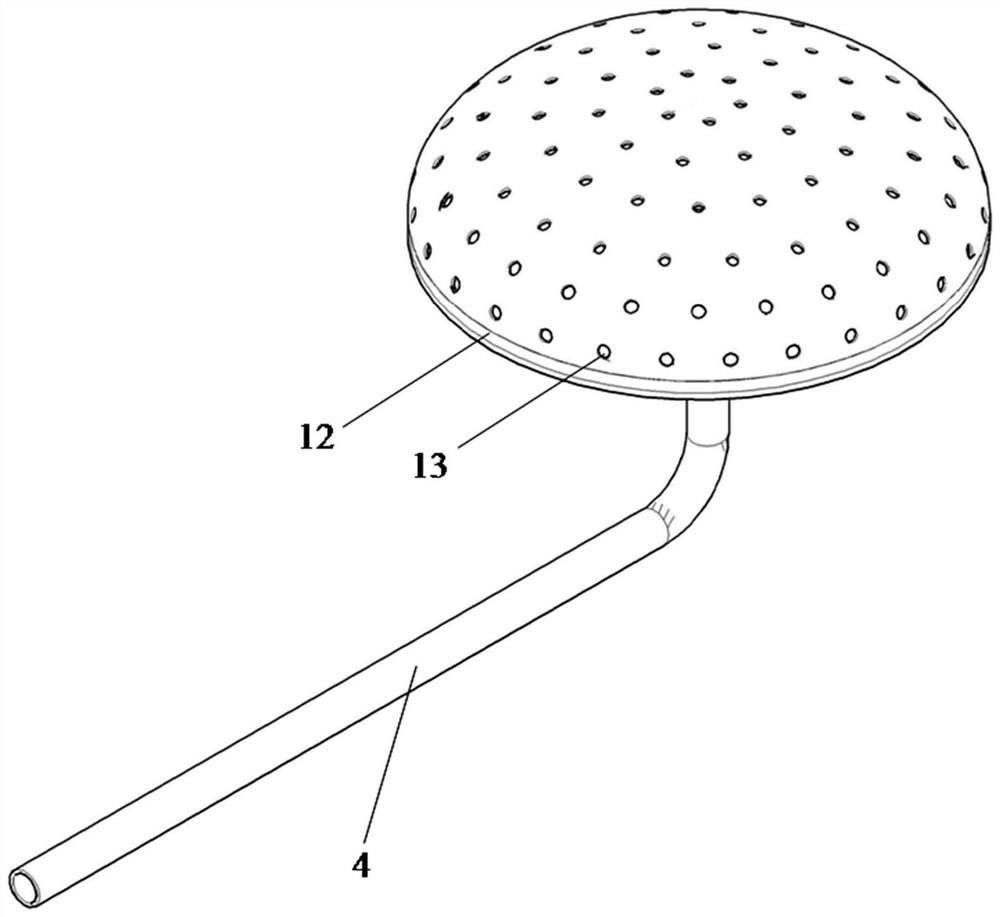

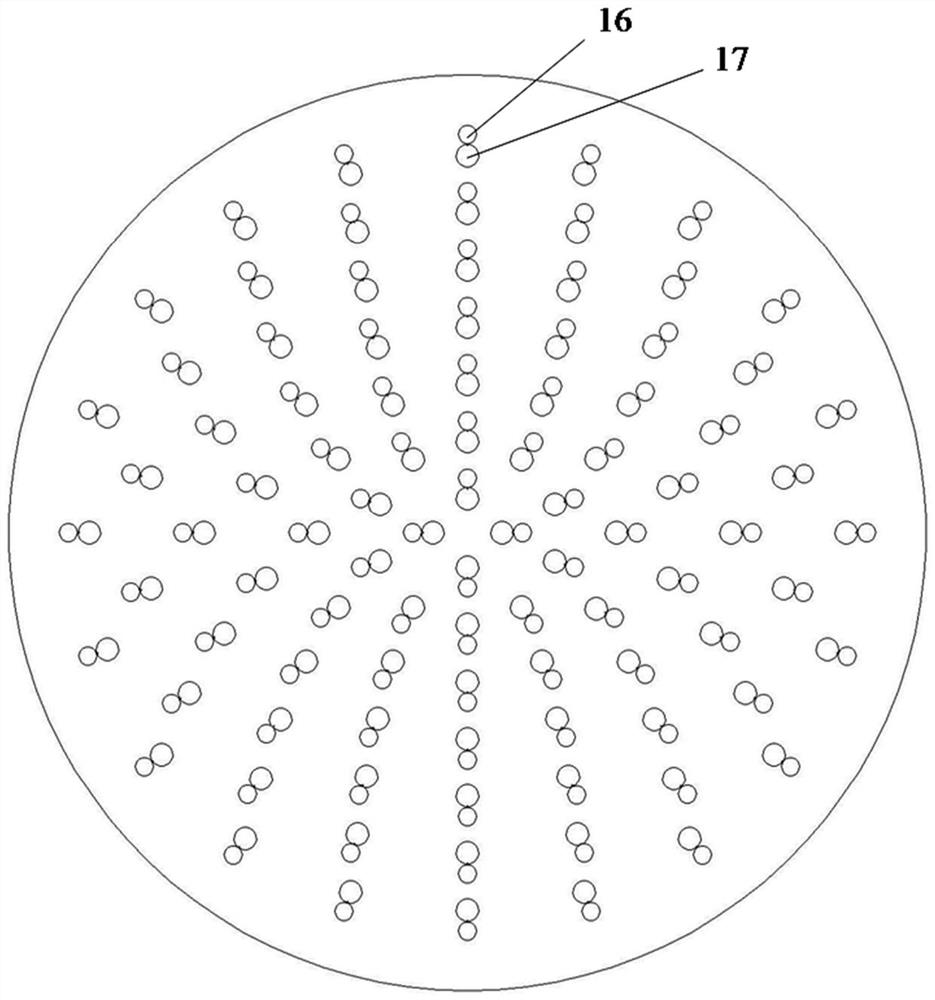

[0055] Desulfurization and denitrification tower: such as Figures 1 to 4 As shown, the desulfurization and denitrification tower provided by the present invention includes a tower body 1, an air inlet 2 and an air outlet 3, and the air inlet 2 and the air outlet 3 are connected to the air inlet pipe 4 and the air outlet pipe respectively. The pre-oxidation layer 5 and the desulfurization and denitrification layer 6, the desulfurization and denitration layer is provided with a desulfurization section 7 and a denitration section 8 along the gas flow direction, the air inlet 2 is arranged on the pre-oxidation layer 5, and the gas outlet 3 is arranged above the desulfurization and denitration layer 6. The desulfurization section 7 and the denitrification section 8 are respectively filled with desulfurization adsorbents and denitrification adsorbents that have catalytic conversion functions for sulfides or nitrides in the gas. The desulfurization adsorbents filled in the desulfuriz...

Embodiment 2

[0065] Desulfurization and denitrification tower: only the gas splitter B15 is installed, and the rest of the structure and connections are the same as those in Embodiment 1.

[0066] The method for gas desulfurization and denitrification in the desulfurization and denitrification tower:

[0067] (1) Pre-treat the gas to be treated, and initially remove impurities such as tar, aromatics, and dust;

[0068] (2) Desulfurization and denitrification: the pretreated gas is passed into the pre-oxidation layer 5 of the desulfurization and denitrification tower, and part of the SO in the gas 2 react with NO and hydrogen peroxide to form SO 3 and NO 2 or further generate H 2 SO 4 and HNO 3 The gas after the pre-oxidation treatment enters the desulfurization section 7 after being dehydrated by the dehydration layer, and performs desulfurization treatment; the gas after the desulfurization treatment enters the denitration section 8 after being shunted by the gas splitter B15, and clea...

Embodiment 3

[0072] Desulfurization and denitrification tower: only one of the gas splitter A14 or the gas splitter B15 is installed, and only one regeneration gas inlet 21 and one desorption gas outlet 22 are installed on the entire desulfurization and denitrification layer 6, and the rest of the structure and connection relationship are the same as in Embodiment 1.

[0073] The method for gas desulfurization and denitrification in the desulfurization and denitrification tower:

[0074] (1) Pre-treat the gas to be treated, and initially remove impurities such as tar, aromatics, and dust;

[0075] (2) Desulfurization and denitrification: the pretreated gas is passed into the pre-oxidation layer 5 of the desulfurization and denitrification tower, and part of the SO in the gas 2 react with NO and hydrogen peroxide to form SO 3 and NO 2 or further generate H 2 SO 4 and HNO 3 The gas after the pre-oxidation treatment is dehydrated by the dehydration layer and then diverted by the gas spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com