Heat recovery coke oven flue gas multi-pollutant ultra-clean emission device and process thereof

A discharge device and heat recovery technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., to achieve the effects of avoiding wear, reliable process operation, and preventing condensation corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The purification process adopts SNCR denitrification / high temperature SCR denitrification and CFB semi-dry desulfurization and dust removal technology to build a coke oven flue gas desulfurization, denitrification and dust removal device, which not only reduces the NOx concentration in the flue gas to 50mg / Nm after purification 3 Below, SO 2 Concentration down to 30mg / Nm 3 Below, the particle concentration is reduced to 5mg / Nm 3 Below, it has the advantages of simple system, convenient operation and maintenance; it can realize the coordinated removal of VOC and dioxin; it has good adaptability to changes in the concentration of pollutants in the inlet flue gas.

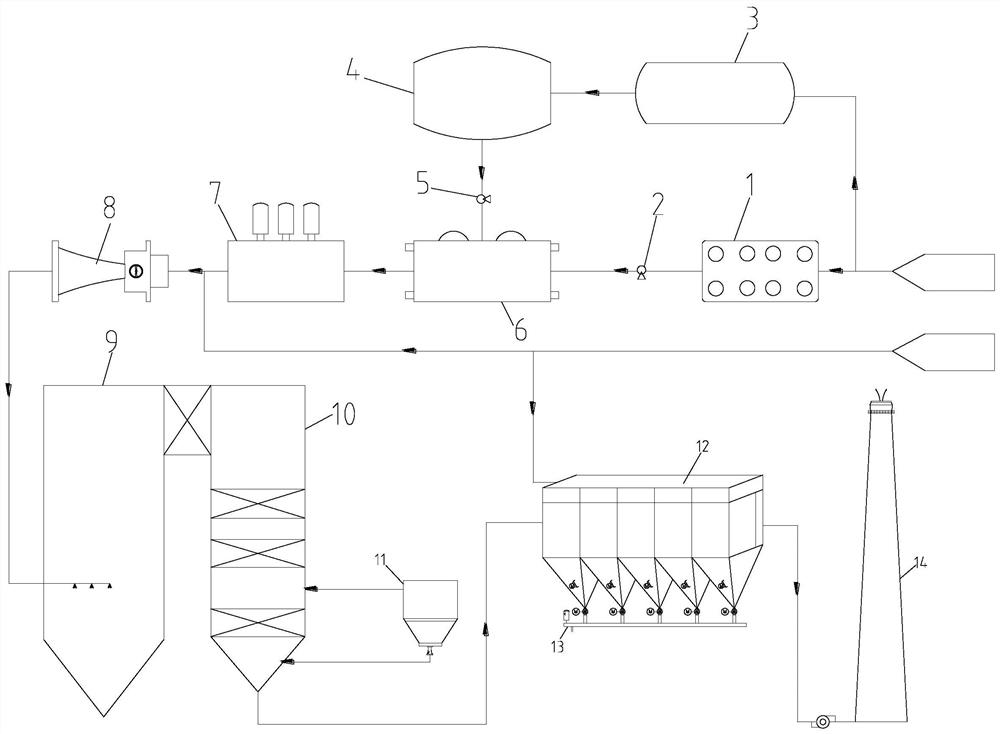

[0036] A heat recovery coke oven flue gas multi-pollutant ultra-clean discharge device of the present invention is a heat recovery coke oven desulfurization, denitrification and dust removal device, which mainly includes a reductant dissolution tank 3, a reductant storage tank 4, an injector 8, and an SCR Rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com