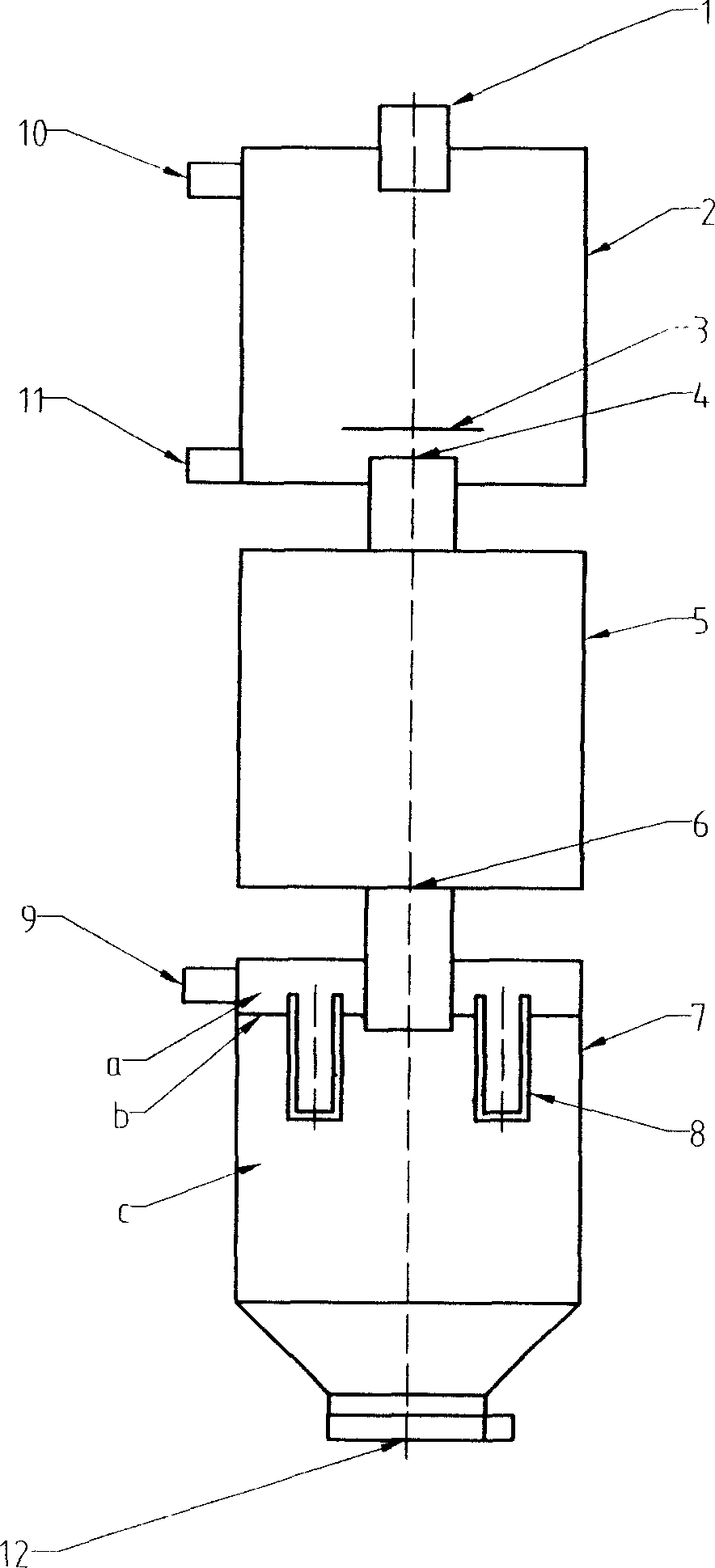

Microwave spray drier

A drying and heating drying technology, applied in the field of spray drying and microwave, to achieve the effect of improving thermal efficiency, small equipment volume, and reducing the possibility of material pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Group No. 1: Liquid (solution, mixed solution, suspension, emulsion, slurry) concentration: about 60% (w / w);

[0021] Particle size range after atomization: less than about 2000μm;

[0022] The particle size range of mist droplets entering the heating and drying chamber: less than about 100 μm;

[0023] Effective microwave electric field strength in heating and drying chamber: about 500 kV / m;

[0024] Heat radiation intensity in heating and drying room: more than 10 kW / square meter

[0025] Heating and drying time: about 0.1 seconds;

[0026] Carrier fluid: air;

[0027] Working pressure in heating and drying chamber: about 0.2MPa (absolute pressure);

[0028] Group

No

liquid thick

Spend

Heating and drying indoor pellets

Electric field strength

(kV / m)

(Second)

carrier stream

body

definitely work

pressure

(MPa)

2

aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com