Pushing mechanism for laser marking device

A push mechanism and laser marking technology, applied in the field of laser marking machines, can solve the problems of untimely retraction and extension of lifting blocks, damage to parts and equipment, and low feeding efficiency, so as to reduce waiting time and improve processing. Efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

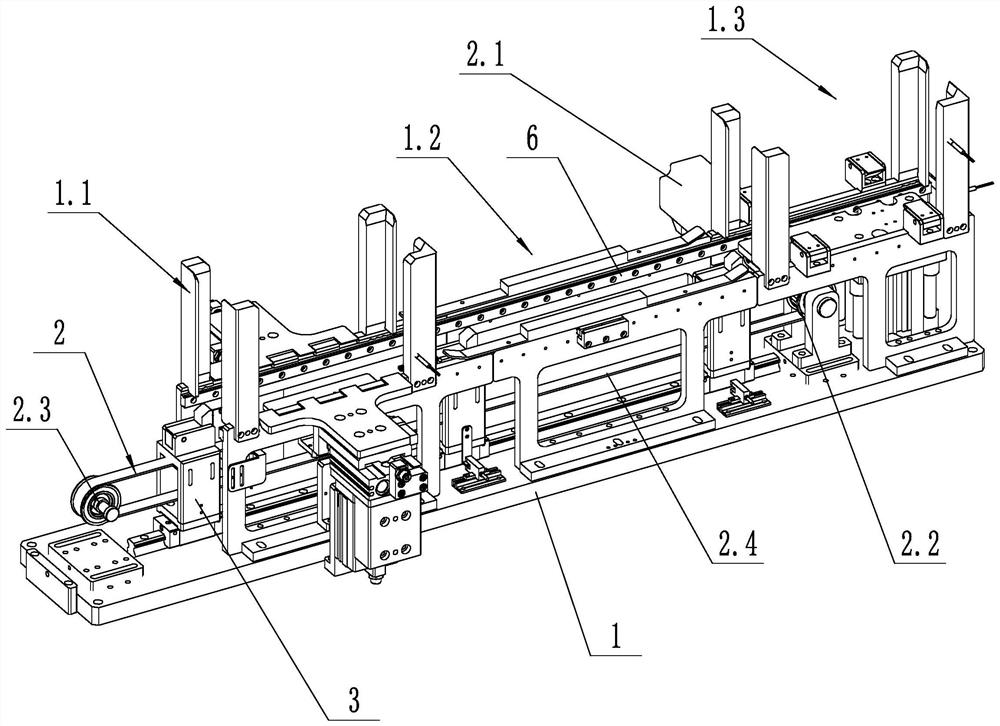

[0023] like figure 1 As shown, a push mechanism for a laser marking device includes a support frame 1, a push drive mechanism 2, a push assembly 3 and a tray, and the support frame 1 includes a loading station 1.1, a processing station 1.2 and an unloading station 1.3, the push assembly 3 and the support frame 1 are slidingly connected through the guide rail slider structure, and the push drive mechanism 2 includes the drive motor 2.1, the driving pulley 2.2, the driven pulley 2.3 and the timing belt 2.4, the driving pulley 2.2 and the driven pulley 2.3 is rotationally connected with the support frame 1, the driving motor 2.1 is fixed with the support frame 1, the driving pulley 2.2 is connected with the output shaft of the driving motor 2.1, and the timing belt 2.4 is arranged on the driving pulley 2.2 and the driven pulley 2.3; the push assembly 3 It is fixed with the synchronous belt 2.4; the upper end of the pushing component 3 is in contact with the side wall of the palle...

Embodiment 2

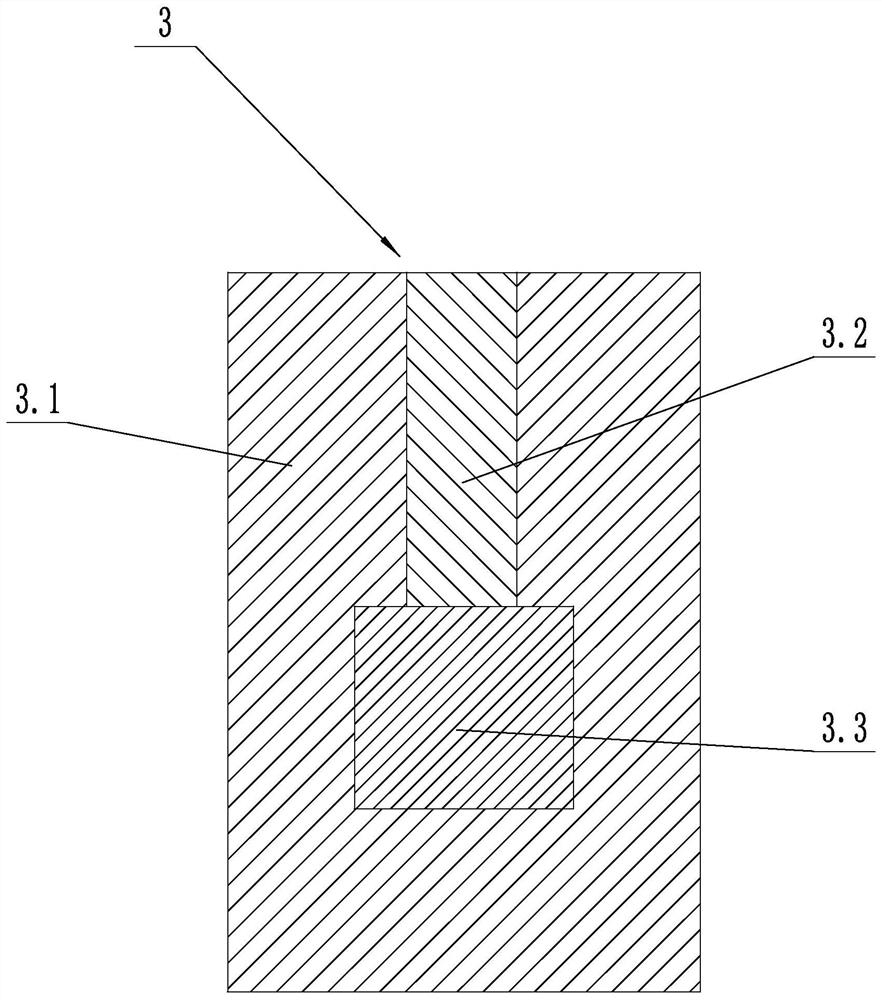

[0026] like figure 2 As shown, the push assembly 3 includes a sliding fixed block 3.1, a lifting block 3.2 and a lifting drive member 3.3, the lifting block 3.2 is slidably connected with the sliding fixed block 3.1 in the vertical direction, the lifting drive member 3.3 is fixed with the sliding fixed block 3.1, and the lifting The telescopic end of the driver 3.3 is connected with the lifting block 3.2. The lifting drive member 3.3 may be a linear drive mechanism such as an air cylinder or an oil cylinder. By implementing the above technical scheme, the lifting block 3.2 can be stretched out or retracted as required, and when the lifting block 3.2 is retracted, the lifting block 3.2 is prevented from contacting the upper pallet, even if there are The tray and the push assembly 3 can also be retracted, thereby reducing waiting time and improving processing efficiency.

Embodiment 3

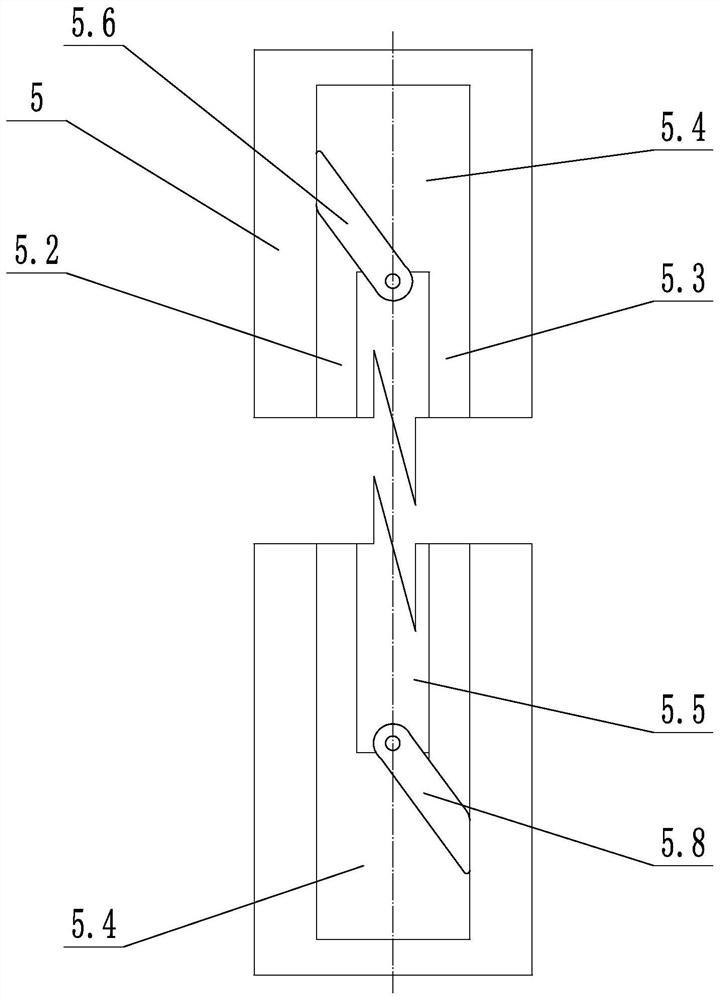

[0028] like image 3 and Figure 4 As shown, the number of the pushing assemblies 3 is two, and the two pushing assemblies 3 are arranged at intervals of one station. The two push assemblies 3 are connected with the same push drive mechanism 2 . The pushing assembly 3 includes a sliding and fixing block 3.1, a lifting block 3.2 and a traverse block 3.4, the sliding and fixing block 3.1 is fixed with the push drive mechanism 2, the sliding and fixing block 3.1 is slidably connected with the support frame 1, and the upper end of the lifting and lowering block 3.2 is connected with the tray. The side walls are in contact, the lifting block 3.2 is slidably connected with the sliding fixed block 3.1 in the vertical direction, the traverse block 3.4 is slidably connected with the sliding fixed block 3.1 in the horizontal direction, and the lifting block 3.2 is provided with a third spring 3.8, the third spring 3.8 One end is connected with the sliding fixed block 3.1, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com