A kind of epoxy resin toughening curing agent and preparation method and application thereof

A technology of epoxy resin and curing agent, applied in the direction of epoxy resin glue, epoxy resin coating, adhesive, etc., can solve the problem of inability to achieve toughening and improving effect, and achieve the improvement of toughening and improving effect, comprehensive functions, and preparation. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

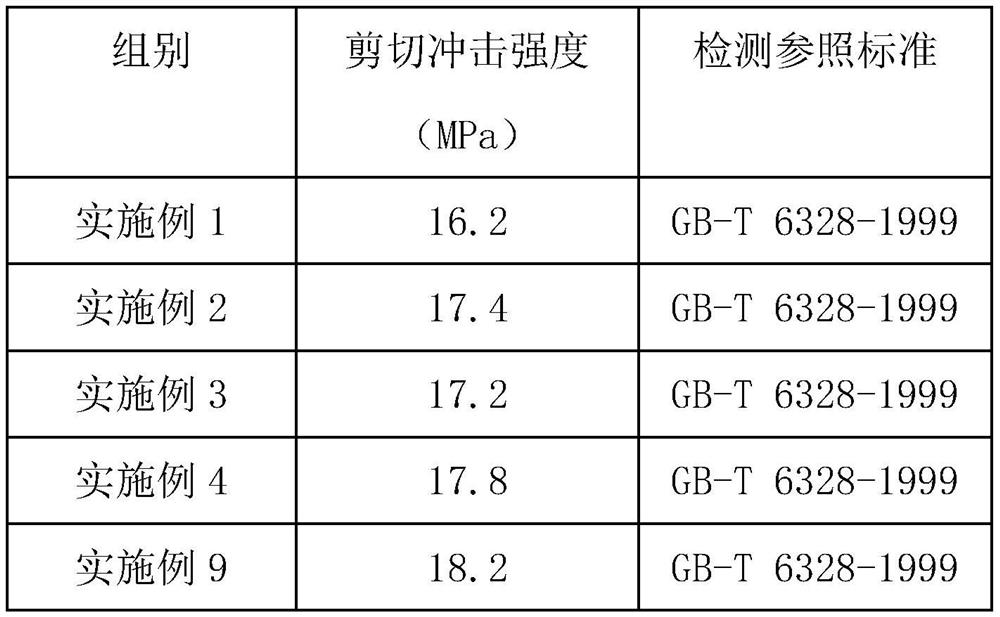

Examples

preparation example Construction

[0017] As another preferred embodiment of the present invention, the preparation method of the modified diphenylmethane-4,4'-diisocyanate comprises: weighing the diphenylmethane-4,4'-diisocyanate and heating it to 45-65 ℃, then vacuumize and add triglyceride and polypropylene glycol to mix, then add acrylate and 2-ethyl-1,3-hexanediol and heat to 45-65 ℃ for insulation, vacuum to remove moisture to obtain the Described modified diphenylmethane-4,4'-diisocyanate.

[0018] As another preferred embodiment of the present invention, in the method for preparing modified diphenylmethane-4,4'-diisocyanate, the vacuuming is performed by using a negative pressure pump until the vacuum degree is 0.6- 60Pa, because it is heated and reacted under negative pressure vacuum conditions to make modified diphenylmethane-4,4'-diisocyanate, while ensuring the normal progress of the reaction, it effectively reduces the reaction temperature caused by excessively high reaction. Moreover, due to the ...

Embodiment 1

[0038]An epoxy resin toughening curing agent, comprising the following raw materials: 80 kilograms of modified diphenylmethane-4,4'-diisocyanate, polyoxypropylene triol (molecular weight is 400, and the hydroxyl group of polyoxypropylene triol is 80 kg). The value is 80 mgKOH / g) 7 kg, polycaprolactone polyol 20 kg, isobutylene-maleic anhydride copolymer 1 kg, imidazole compound 20 kg, and an appropriate amount of organic solvent. Wherein, the amount of the organic solvent used is 60 wt % of the weight of the modified diphenylmethane-4,4'-diisocyanate. The imidazole compound is dimethylimidazole. The organic solvent is N,N-dimethylformamide.

[0039] In this embodiment, the preparation method of the epoxy resin toughening curing agent specifically includes the following steps:

[0040] 1) According to the mass ratio of diphenylmethane-4,4'-diisocyanate, triglyceride, polypropylene glycol, acrylate and 2-ethyl-1,3-hexanediol is 12:20:18:1: Diphenylmethane-4,4'-diisocyanate wa...

Embodiment 2

[0044] An epoxy resin toughening curing agent, comprising the following raw materials: 120 kilograms of modified diphenylmethane-4,4'-diisocyanate, polyoxypropylene triol (molecular weight is 1200, and the hydroxyl group of polyoxypropylene triol is 1200 kg). The value is 120 mgKOH / g) 15 kg, polycaprolactone polyol 40 kg, isobutylene-maleic anhydride copolymer 6 kg, imidazole compound 50 kg, and an appropriate amount of organic solvent. Wherein, the amount of the organic solvent is 130 wt % of the weight of the modified diphenylmethane-4,4'-diisocyanate. The imidazole compound is dimethylimidazole. The organic solvent is N,N-dimethylformamide.

[0045] In this embodiment, the preparation method of the epoxy resin toughening curing agent specifically includes the following steps:

[0046] 1) According to the mass ratio of diphenylmethane-4,4'-diisocyanate, triglyceride, polypropylene glycol, acrylate and 2-ethyl-1,3-hexanediol is 18:40:40:8: Weigh diphenylmethane-4,4'-diisoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com