Pregelatinized starch with excellent thixotropic smoothness, and preparation method thereof

A pre-gelatinized starch and smooth technology, applied in the direction of filling slurry, etc., can solve the problems of poor thixotropic smoothness, laborious scraping, sticky hand feeling, etc., achieve good thixotropy and smoothness, and reduce material consumption , Improve the effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

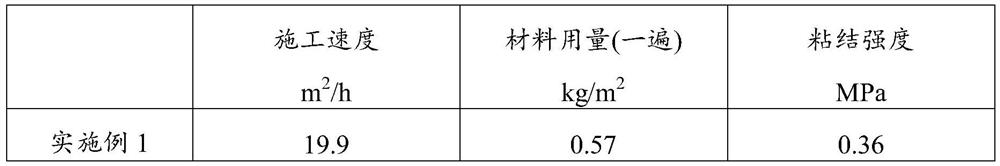

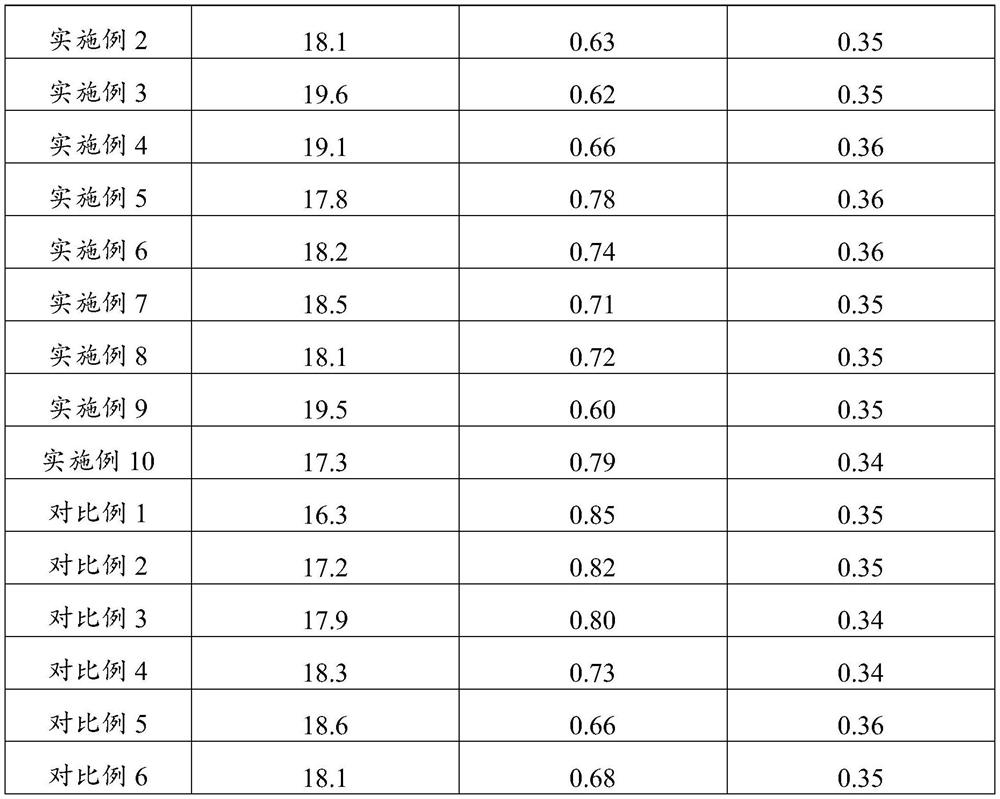

Examples

Embodiment 1

[0029] A pregelatinized starch with good thixotropic smoothness, comprising the following components in parts by mass:

[0030] 100 parts of starch, 1 part of lithium magnesium silicate, 0.02 parts of sodium pyrophosphate, 0.3 parts of surfactant, and 15 parts of water.

[0031] Wherein, the surfactant is sodium α-alkenyl sulfonate and cocamidopropyl betaine with a mass ratio of 95:5.

[0032] The preparation method of the good pregelatinized starch of this thixotropic smoothness is as follows:

[0033] 1) Dissolve lithium magnesium silicate in water, add sodium pyrophosphate, stir and disperse for 240 minutes, so that the lithium magnesium silicate is fully activated and dissociated;

[0034] 2), add a surfactant to the obtained in step 1), and disperse for 30 minutes to obtain a lithium magnesium silicate solution;

[0035] 3), adding the lithium magnesium silicate solution obtained in step 2) into the starch, stirring and dispersing for 60 minutes, and then standing for 1...

Embodiment 2

[0039] The difference with embodiment 1 is:

[0040] The pregelatinized starch with good thixotropic smoothness of the present embodiment comprises the composition of the following parts by mass:

[0041] 100 parts of starch, 0.5 part of lithium magnesium silicate, 0.01 part of sodium pyrophosphate, 0.1 part of surfactant, and 5 parts of water.

[0042] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0044] The difference with embodiment 1 is:

[0045] The pregelatinized starch with good thixotropic smoothness of the present embodiment comprises the composition of the following parts by mass:

[0046] 100 parts of starch, 1.2 parts of lithium magnesium silicate, 0.03 parts of sodium pyrophosphate, 0.5 parts of surfactant, and 10 parts of water.

[0047] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com