Novel additive printing material and application thereof in ceramic 3D printing equipment

A technology of additive printing and 3D printing, applied in the direction of additive processing, metal processing equipment, 3D object support structure, etc., to achieve the effect of uniform and smooth discharge and good connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A new type of additive printing material, by weight percentage, comprising: 84.4% aliphatic polyurethane; 0.8% water-based defoamer; 0.6% wetting agent; 0.5% leveling agent; 2.8% dispersant; 5.9% pigment; and The water-based curing agent is 5%. The new additive printing material has a viscosity value of 98000 cps after testing.

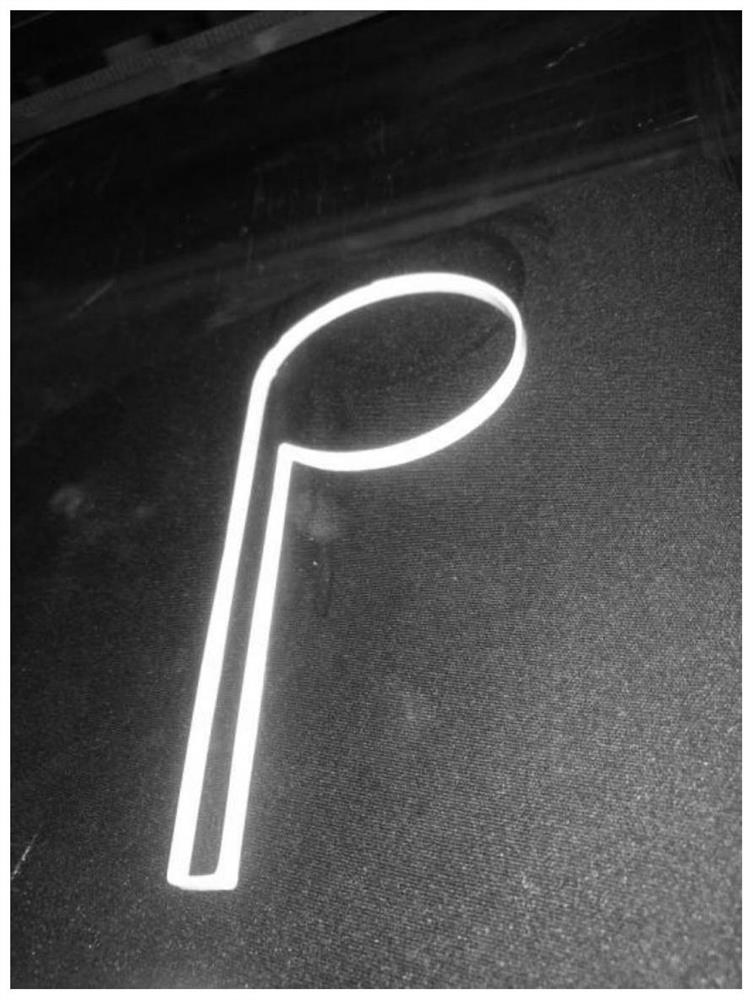

[0054] Use the PET flat base cloth as the base of 3D printing, put an appropriate amount of the new additive printing material provided in this embodiment into the ink cartridge of the ceramic 3D printing device, and add a suitable after the outlet of the ink cartridge. Matched caliber screw extruder. Design the three-dimensional pattern model to be 3D printed as a musical note The line model of the design model file is sliced and sent to the 3D printing control host. Set the 3D printing working parameters, specifically, set the size of the printing needle nozzle to 0.8mm, the printing line width to 0.5mm, the distance between the substrat...

Embodiment 2

[0056] The difference from Example 1 is that the new additive printing material provided in this example contains, by weight percentage: 83.1% of aliphatic polyurethane; 0.8% of water-based defoamer; 0.6% of wetting agent; leveling agent 0.5%; 3% dispersant; 2% pigment red, 5% pigment yellow; and 5% water-based curing agent. After testing, the new additive printing material has a viscosity of 100,000 cps.

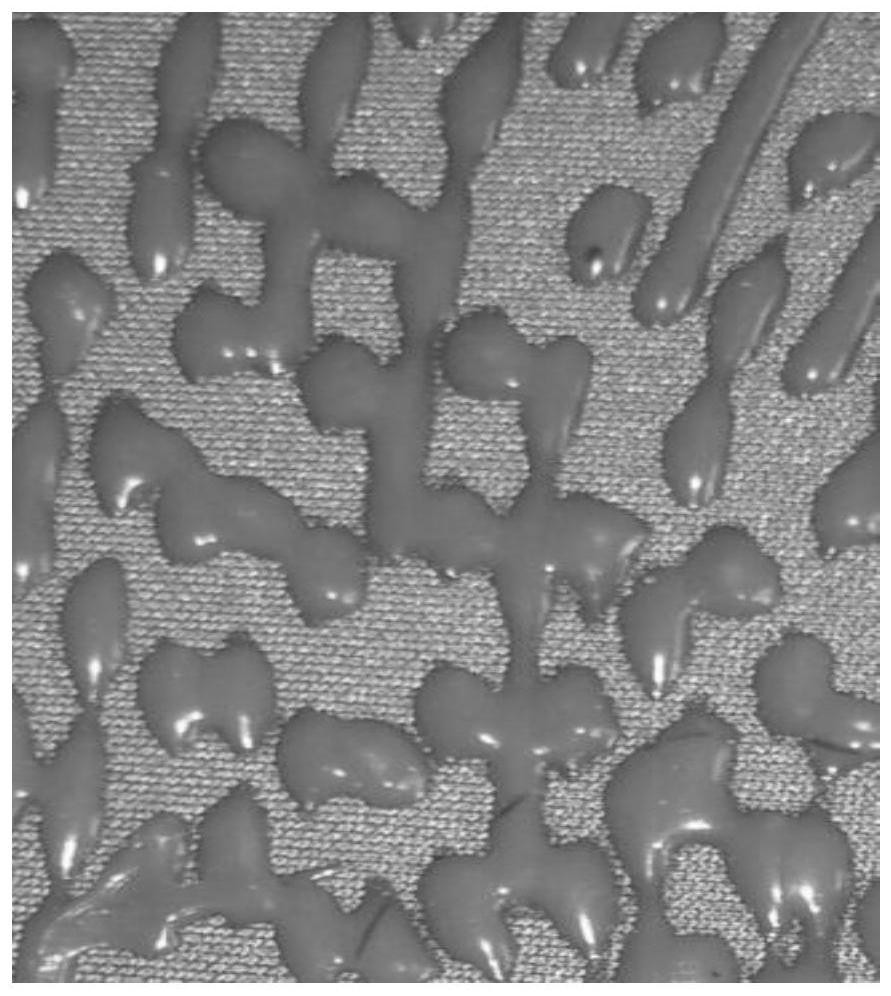

[0057] Using polyester-spandex blended flat fabric as the base for 3D printing, put an appropriate amount of the new additive printing material provided in this embodiment into the ink cartridge of the ceramic 3D printing device, and add a Suitable diameter screw extruder. Design the three-dimensional pattern model to be 3D printed as an irregular leveling pattern model, slice the design model file, and send it to the 3D printing control host. Set the working parameters of 3D printing, specifically, set the size of the printing needle nozzle to 1.2mm, the printing line wid...

Embodiment 3

[0059] The difference from Example 2 is that the new additive printing material provided in this example contains, by weight percentage: 78% of aliphatic polyurethane; 1.2% of water-based defoamer; 0.8% of wetting agent; 0.8% of leveling agent %; 5.2% of dispersant; 4% of pigment red, 4% of pigment yellow; and 6% of water-based curing agent. After testing, the new additive printing material has a viscosity value of 96000cps.

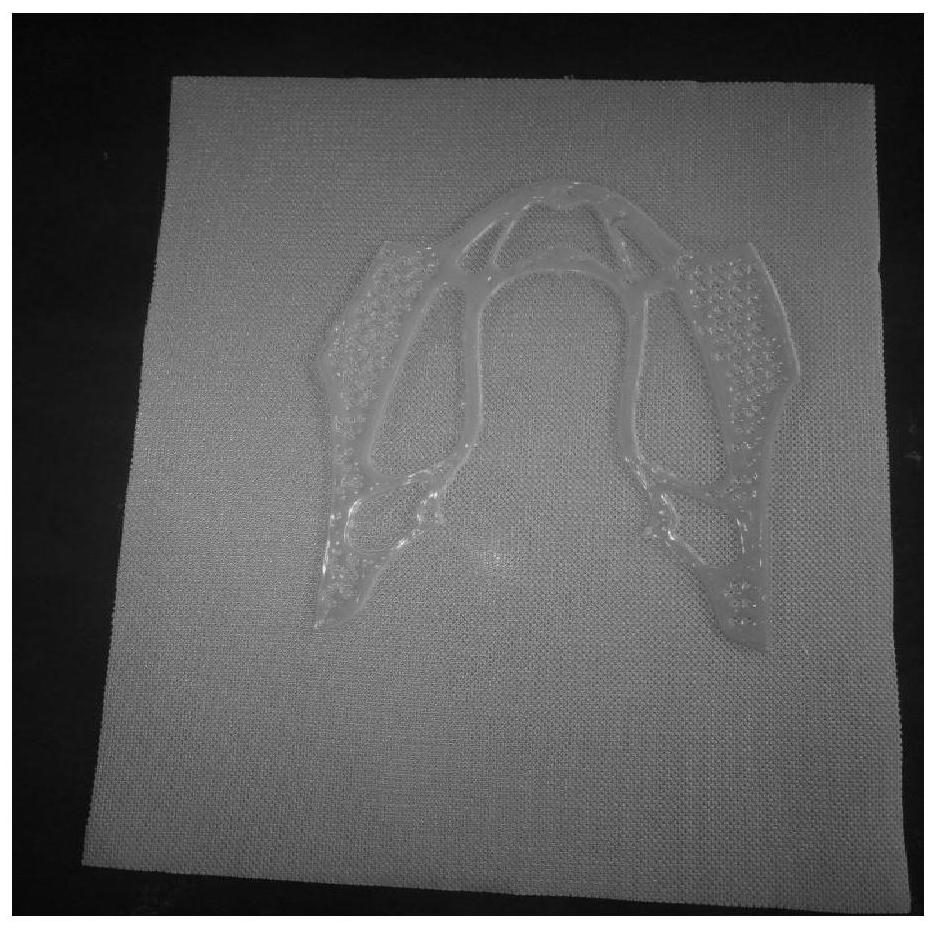

[0060] In this embodiment, the three-dimensional pattern model to be 3D printed is designed as a vamp model with a special pattern design. Set the working parameters of 3D printing, specifically, set the size of the printing needle nozzle to 1.2mm, the printing line width to 0.1mm, the distance between the substrate and the printing needle nozzle to 5mm, the compressed air pressure to 0.1mPa, and the viscous fluid to advance evenly The propulsion magnification (extrusion magnification) of the device (screw extruder) is 0.5 times, the retraction length is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap