A method for preparing non-equilibrium ultrafine microstructure alloys by using high-energy beams

A high-energy beam, non-equilibrium technology, applied in the field of metal material preparation and processing, can solve the problems of limited solid solution degree and thin thickness of alloying elements, and achieve the effect of adjustable elastic modulus, high elastic modulus and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation of Al-Si alloy material based lightweight superhard

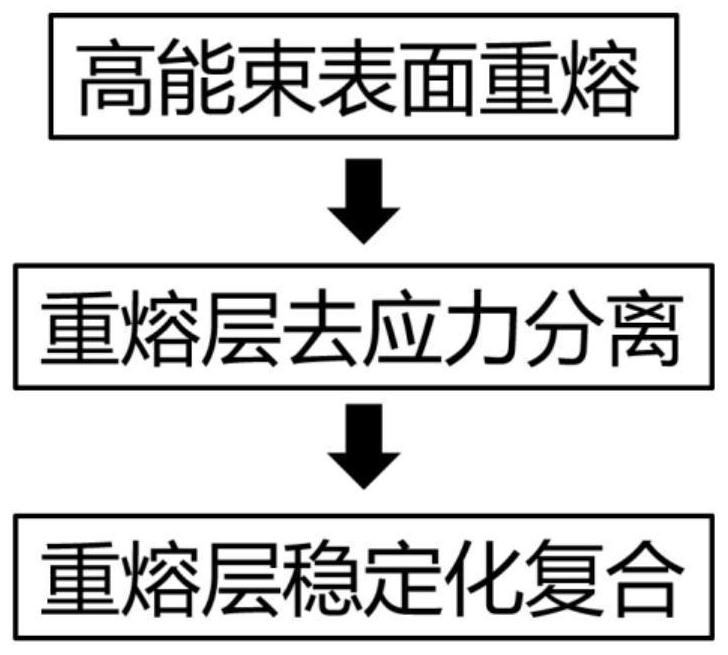

[0048] Embodiment of the present invention, the alloy composition is Al-10Si-2Mg-0.5Li-0.2Fe, addition of Si, Mg, Li alloy to reduce the density of the alloy while increasing the strength of the effect of small amount of Fe added for improving strength. By conventional ingot casting method to obtain the alloy. The density of the national standard GB / T 1423-1996 "precious metals and their alloys Density Test Method" as measured in the drainage alloy is 2.61g / cm 3 , Pure Al is lower than the density of 2.70g / cm 3 , To the light effect. Then, according to the process proposed by the invention (see, figure 1 ): High energy beam remelting surface layer remelted to stress → → remelted layer separation stabilizing compound, prepared unbalanced ultra fine grain Al-10Si-2Mg-0.5Li-0.2Fe alloy.

[0049] The surface of the high energy beam remelting in commercial selective laser melting apparatus, the la...

Embodiment 2

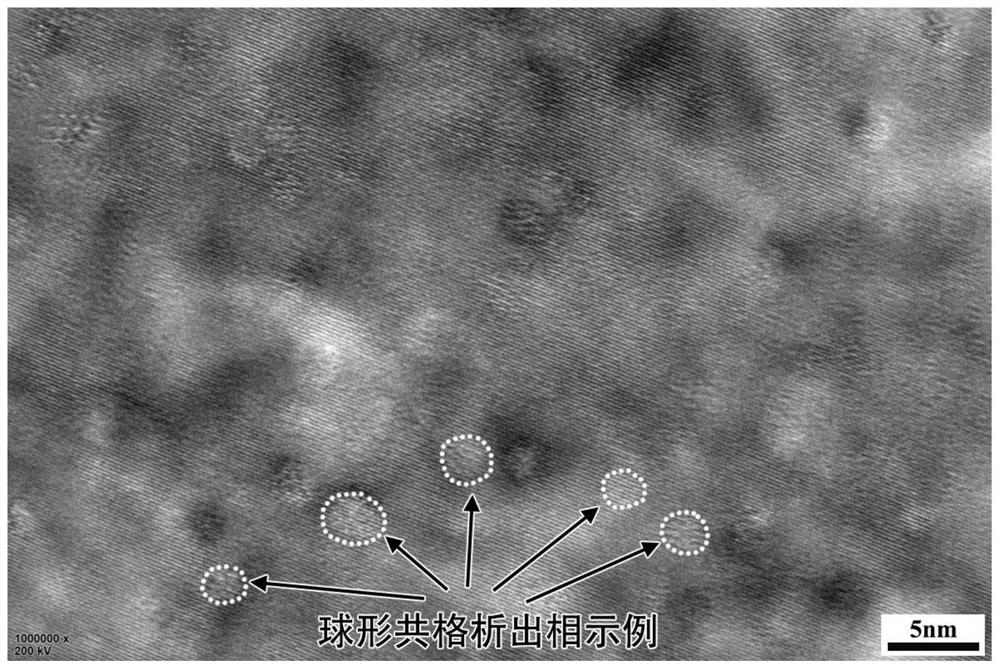

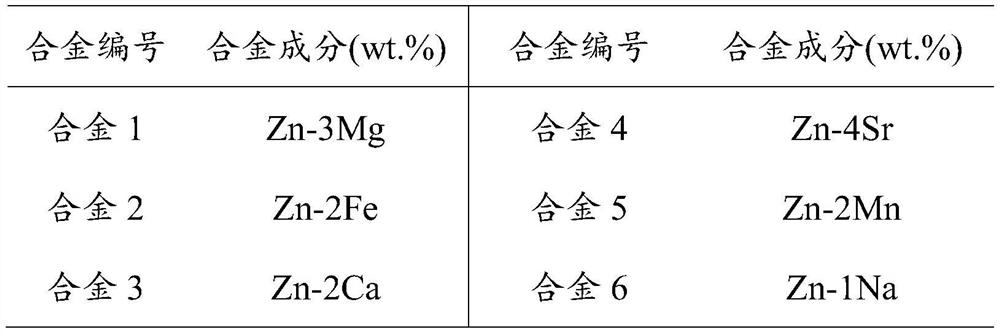

[0052] Example 2: Preparation of high-strength zinc alloy strong function degradation

[0053] Example 6 of the present embodiment which degraded the zinc alloy composition as shown in Table 2-1. Add Mg, Fe, Ca, Sr, Mn, Na alloying elements in the object are pure zinc is zinc improve the strength and exerts beneficial effect of these nutrients and trace elements on the human body. To better illustrate the effect of the present invention, provided the following Comparative Example, a conventional casting method the composition of six kinds of zinc alloy was prepared as shown in Table 2-1, first high purity metal raw material into the smelting furnace according to the ratio ceramic crucible, vacuum, when the pressure decreases below 10 Pa (degree of vacuum), purged with argon protection, when the argon gas introduced into the furnace to a pressure of 0.04MPa, transmission starts heating, the alloy melt is heated to 700 ~ 750 ℃ refining incubated for 5 to 10 minutes, then poured in...

Embodiment 3

[0060] Preparation of non-equilibrium ultra fine titanium / magnesium composite: Example 3

[0061]This embodiment of the process proposed by the invention: a surface layer remelted remelting → → remelted layer separation stress to stabilize the composite prepared unbalanced ultra fine titanium / magnesium composite high-energy beam. Preparation Example of the present embodiment four kinds of titanium / magnesium composite material is Ti-6Al-4V / Mg-6Zn, Ti-5Mo-5V-8Cr-3Al / Mg-9Al-1Zn, Ti-6Al-3.5Mo-1.5Zr-0.3 si / Mg-3.5Li, Ti-32Mo / Mg-6Sn-5Zn.

[0062] High energy beam remelting the surface of the electron beam in a commercial district melting apparatus, the titanium alloy is an electron beam power parameters 150 ~ 500W, the scanning speed of 80 ~ 200mm / s, pitch pass 30 ~ 50μm. Magnesium alloy process parameters of the electron beam power of 100 ~ 300W, the scanning speed of 150 ~ 300mm / s, pitch pass 30 ~ 50μm. Measured electron beam remelting the surface layer has a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com