A system and method for extracting gas pressure swing adsorption enrichment and production increase for underground coal mines

A pressure swing adsorption and gas extraction technology, which is applied in separation methods, chemical instruments and methods, and production fluids, etc., can solve the problems of poor fault tolerance, system shutdown, and huge investment, so as to avoid serious air leakage in drilling holes and reduce energy consumption. Consume cost and ensure the effect of conveying safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

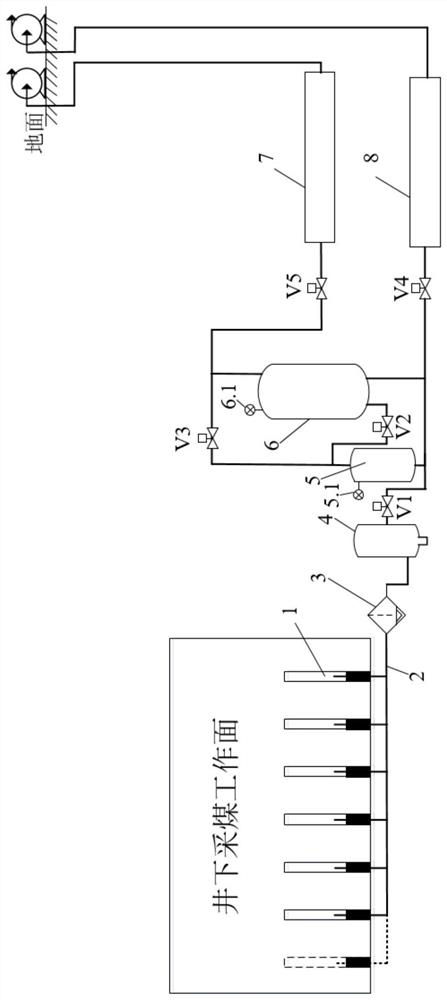

[0026] Such as figure 1 As shown, the present invention provides a gas drainage pressure swing adsorption enrichment and production increase system for underground coal mines, including a gas drainage branch pipe 2, a dust removal device 3, a gas-water separator 4, a dehydration device 5, a methane adsorption tank 6, Coal mine low negative pressure drainage system 7 and coal mine high negative pressure drainage system 8. In this embodiment, the dedusting device 3 adopts a spray dedusting type wet dedusting device, and the dehydration device 5 has a volume of 0.05 to 0.3 m 3 , methane adsorption tank 6 volume is 0.1 ~ 1m 3 . In addition, the reasonable selection of the height and diameter ratio of the methane adsorption tank 6 has an important influence on the separation and concentration of low-concentration gas. In this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com