Variable frequency heat pump unit and control method thereof

A technology for heat pump units and units, applied in the direction of heat pumps, compressors, refrigerators, etc., can solve the problems of reducing the flexibility of use of heat pump units, reducing the service life of compressors, and consuming large power, so as to achieve strong applicability and reduce power loss , Improve the effect of cooling and heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

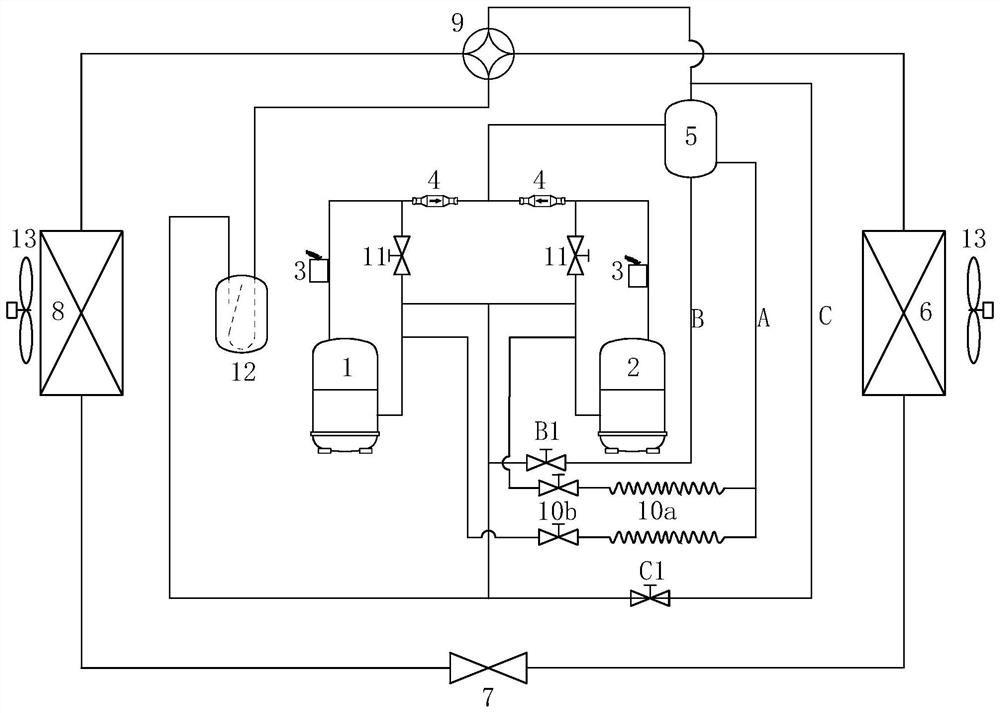

[0042] Such as figure 1 As shown, the frequency conversion heat pump unit of Embodiment 1 of the present invention includes: a refrigerant formed by a compressor, an oil separator 5, a reversing valve 9, a condenser 6, a throttling mechanism 7, and an evaporator 8 connected in series through a refrigerant pipeline. Circulation circuit; between the oil separator 5 and the air return port of the compressor, a parallel normal oil return oil circuit A and a forced oil return oil circuit B are arranged; a system pressure balance pipe is arranged between the high pressure side and the low pressure side of the unit Road C.

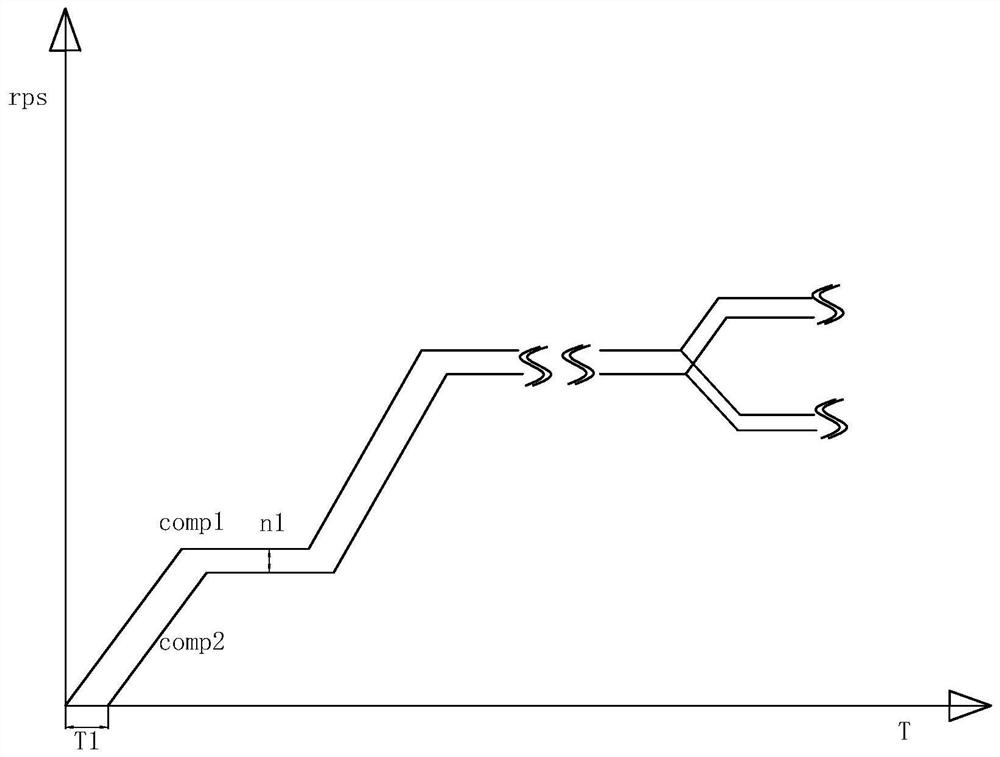

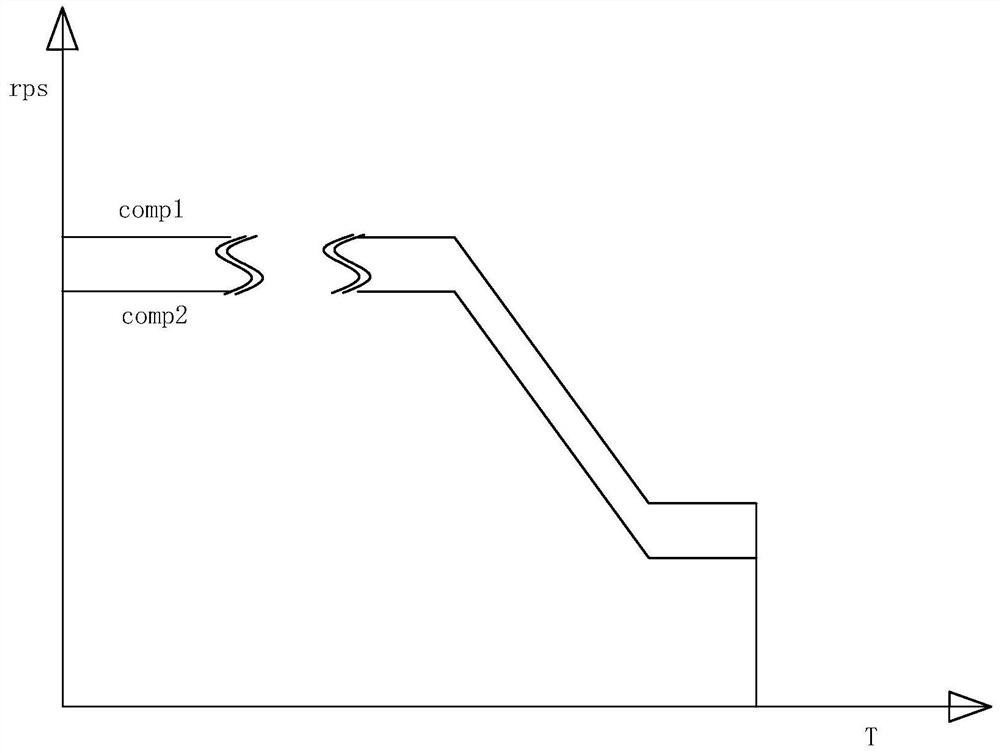

[0043] Wherein, there are two compressors arranged in parallel, that is, 1# compressor 1 and 2# compressor 2, both of which are inverter compressors. The variable frequency compressor can adjust the running speed of the compressor at any time, and will not be turned on frequently, which greatly reduces the power loss caused by frequent shutdown and restart, and ...

Embodiment 2

[0058] Such as Figure 6 to Figure 9 shown, and refer to figure 1 : The frequency conversion heat pump unit and the second embodiment of the present invention figure 1 The variable frequency heat pump unit in Embodiment 1 shown has basically the same structure, except that three variable frequency compressors (namely comp1, comp2 and comp3) are arranged in parallel in the variable frequency heat pump unit in Embodiment 2, which will not be shown in detail here.

[0059] In the frequency conversion heat pump unit according to Embodiment 2 of the present invention, the control method of the three compressors is basically the same as that of the two compressors in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com