Ultrasonic probe assembly

An ultrasonic and component technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, which can solve the problems of aging and cracking of skin-transparent rubber water films, easy damage and compression of sealing film screws, and maintenance costs. Increase and other problems, to achieve the effect of simplifying the cleaning and maintenance process and difficulty, not easy to be corroded by oils and fats, and easy to process and produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

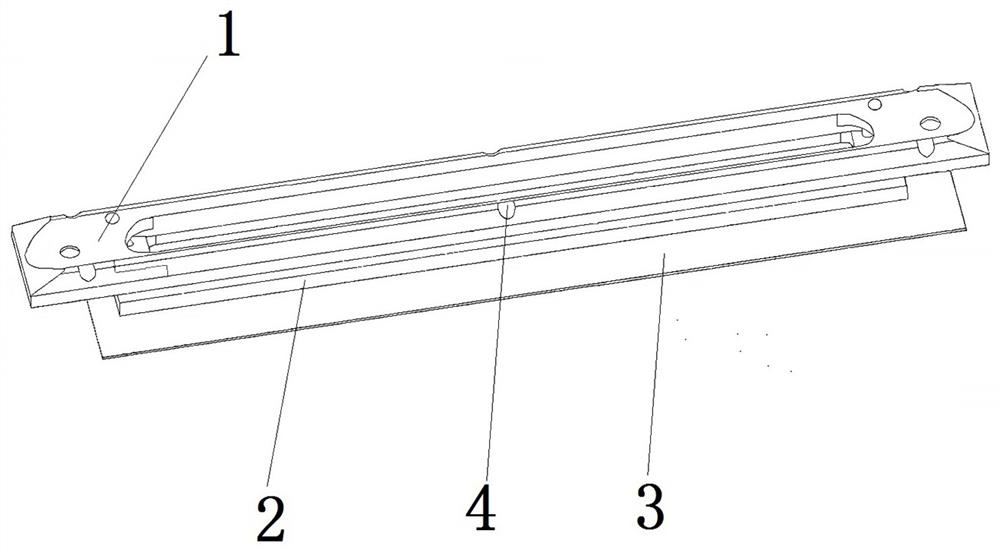

[0013] An ultrasonic probe assembly, comprising a wear-resistant plate 1, a sealing film plate 2, a water film 3, a probe shoe and a probe, the wear-resistant plate 1 and the sealing film plate 2 are hollow inside, the wear-resistant plate 1, the sealing film A number of screw holes 4 are evenly distributed around the membrane plate 2, water film 3 and the probe shoe. The bottom of the wear-resistant plate 1 is the sealing film plate 2, and the bottom of the sealing film plate 2 is the water film 3. The water The bottom of the film 3 is a probe, and the probe is provided with a cavity inside, and a probe is fixed in the cavity, and the wear-resistant plate 1, the sealing plate 2, the water film 3 and the probe are fixedly connected by screws .

[0014] The sealing film plate 2 is metal.

[0015] Described screw hole 4 matches with screw.

[0016] The water film 3 is a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com