Rapid prediction method for heat transfer characteristic of periodic structure composite material at high temperature

A periodic structure, composite material technology, applied in special data processing applications, instruments, design optimization/simulation, etc., can solve the problems of rarely considering the radiation transfer process, not analyzing the radiation transfer process, etc., to improve the calculation rate and efficiency. predicted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

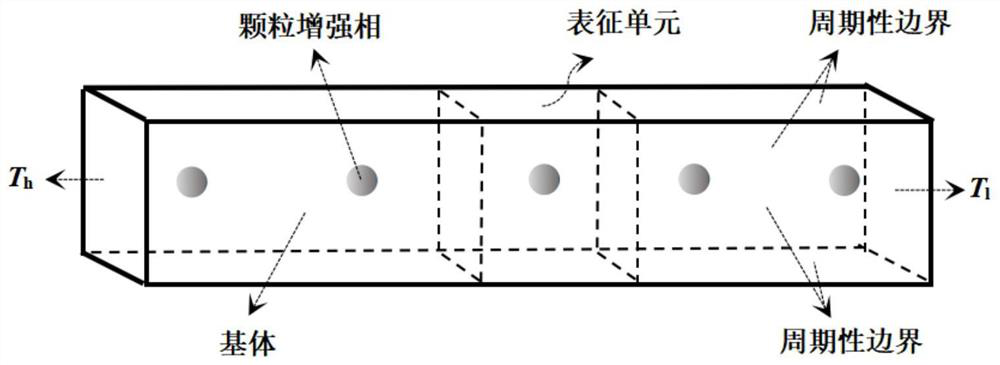

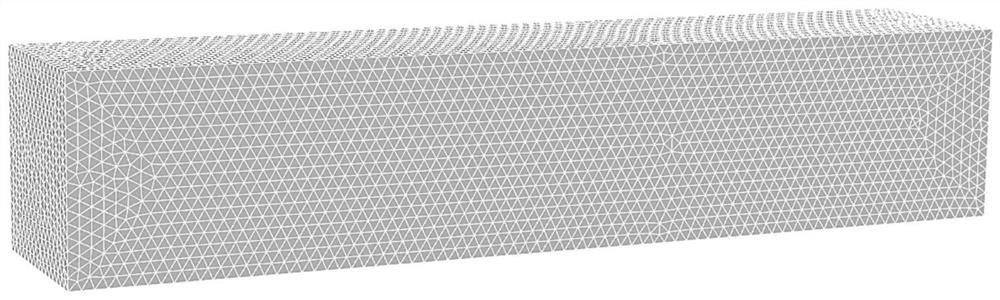

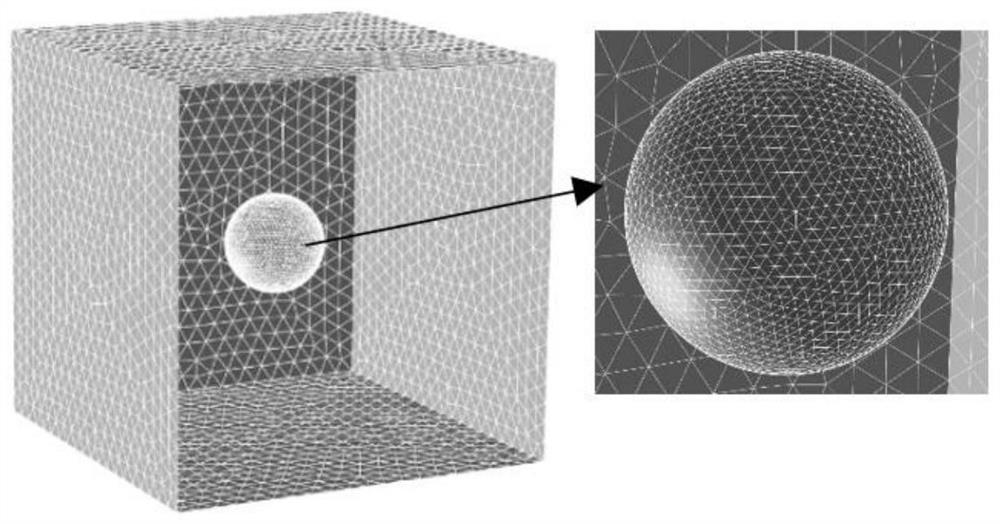

[0050] The invention is a rapid prediction method for the heat transfer characteristics of periodic structure composite materials at high temperature, which adopts the homogenization method of multi-scale asymptotic expansion, and decomposes the temperature field of the composite material into the representation of the macroscopic average field and the mesoscopic scale Intra-unit fluctuations are solved separately based on the information transfer mechanism between macro and meso scales, and finally a multi-scale reconstructed temperature field is obtained. The calculation procedure of the heat transfer characteristics of periodic structure composites at high temperature is illustrated by taking the heat insulation material with added particle-reinforced phase as an example.

[0051] Specifically, the physical model of the thermal insulation mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| scattering coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com