Reinforcing steel bar machining equipment for reinforced concrete drainage pipe

A reinforced concrete and steel bar processing technology, applied in the field of construction equipment, can solve problems such as steel bar displacement and cutting, and achieve the effect of increasing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

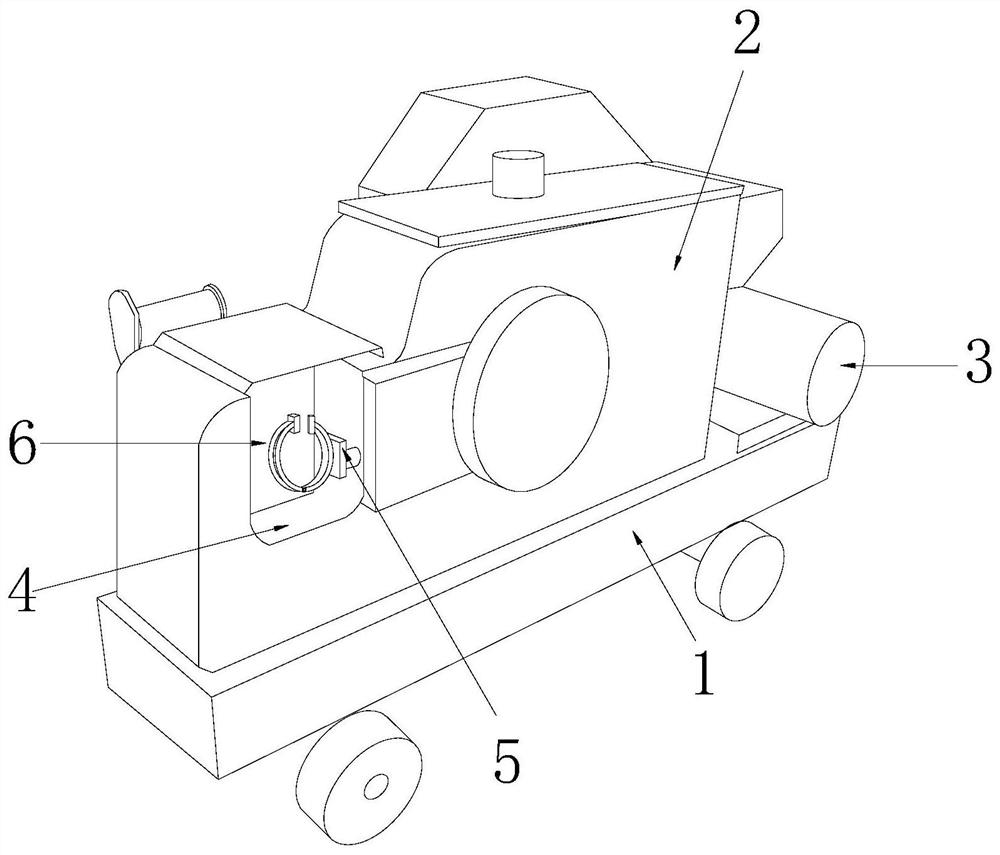

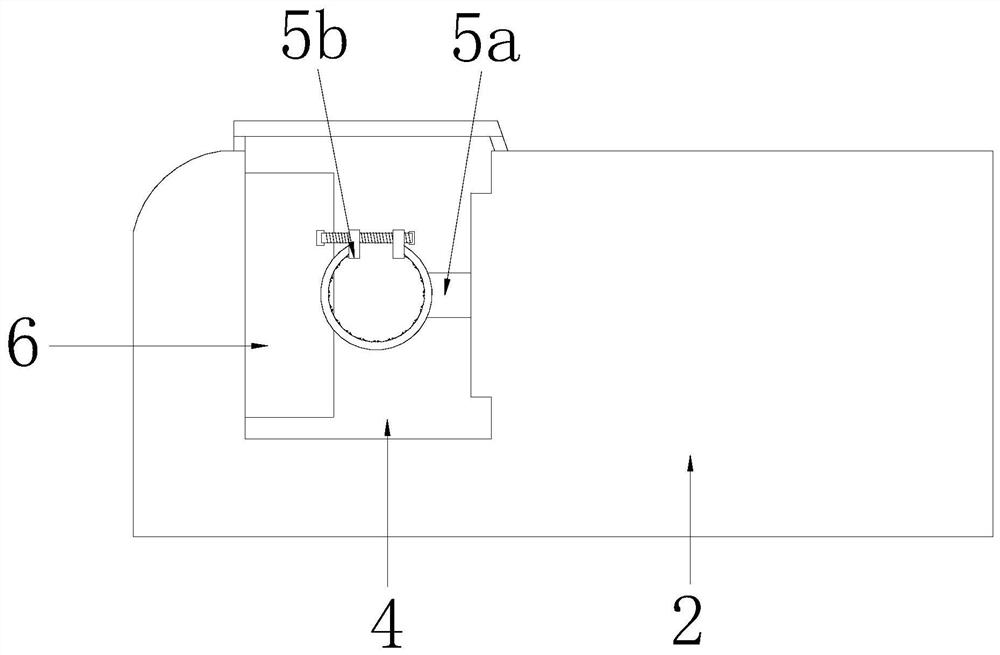

[0029] like Figure 1-Figure 4 As shown, the present invention provides a technical scheme of reinforced concrete drainage pipe reinforcement processing equipment:

[0030] like Figure 1-Figure 3 As shown, a reinforced concrete drainage pipe reinforcement processing equipment, its structure includes a mobile frame 1, equipment main body 2, drive motor 3, processing tank 4, protective device 5, cutting piece 6, the equipment main body 2 is installed on the mobile frame 1 On the upper surface, the driving motor 3 is located on the right side of the equipment main body 2 and cooperates, the processing tank 4 is located on the left side of the equipment main body 2 and is an integrated structure, and the protection device 5 is located on the right side of the processing tank 4 and Located on the front side, the cutting member 6 is installed on the left side inside the processing tank 4, the protection device 5 includes a spring pushing structure 5a and a fastening mechanism 5b, ...

no. 2 example

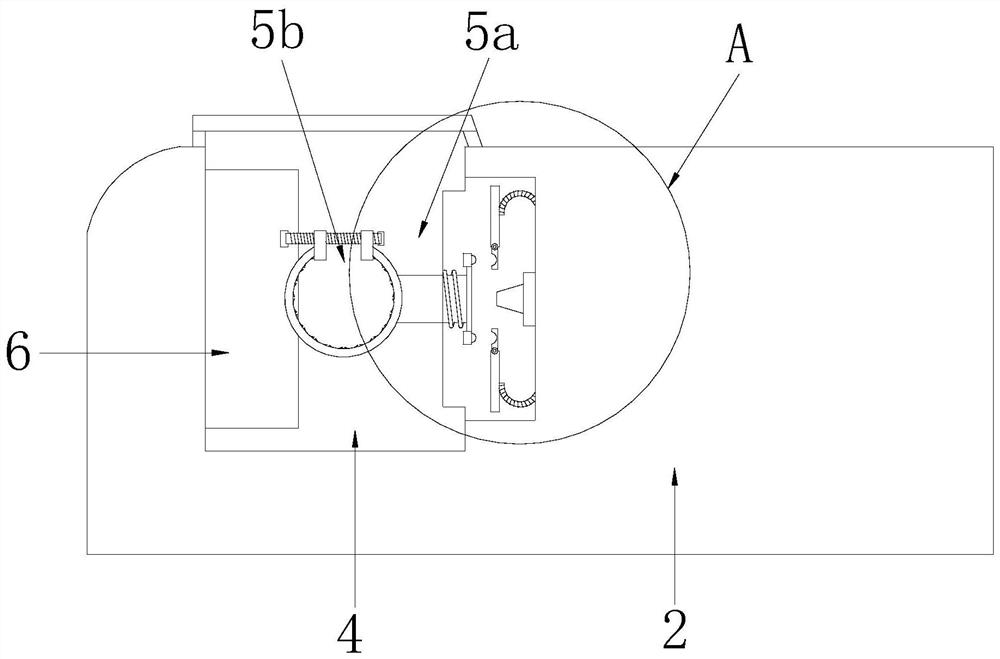

[0039] like Figure 4-Figure 6 As shown, the present invention provides a technical scheme of reinforced concrete drainage pipe reinforcement processing equipment:

[0040] like Figure 4-Figure 5 As shown, a reinforced concrete drainage pipe reinforcement processing equipment, its structure includes the fastening mechanism 5b including arc sleeve 5b1, matching torsion bar 5b2, perforated plate 5b3, screw rod 5b4, connecting rod 5b5, return spring 5b6, limit plate 5b7, there are two arc sleeves 5b1 and they are respectively connected by matching torsion bars 5b2; There are two perforated plates 5b3, the connecting rod 5b5 is installed on the right surface of the arc sleeve 5b1 provided on the right side, and extends into the cavity 5a1, and the return spring 5b6 is nested with the end of the connecting rod 5b5 and is located inside the cavity 5a1, the limiting plate 5b7 is installed on the right end of the connecting rod 5b5, and cooperates with the buckle groove plate 5a24,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap