Continuous indexing gear grinding method for cycloidal bevel gear

A cycloid bevel gear and indexing technology, applied in the direction of elements with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of large cost loss, no interchangeability, and can only be used in pairs , to achieve the effect of reducing the continuous indexing speed, ensuring its own strength, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

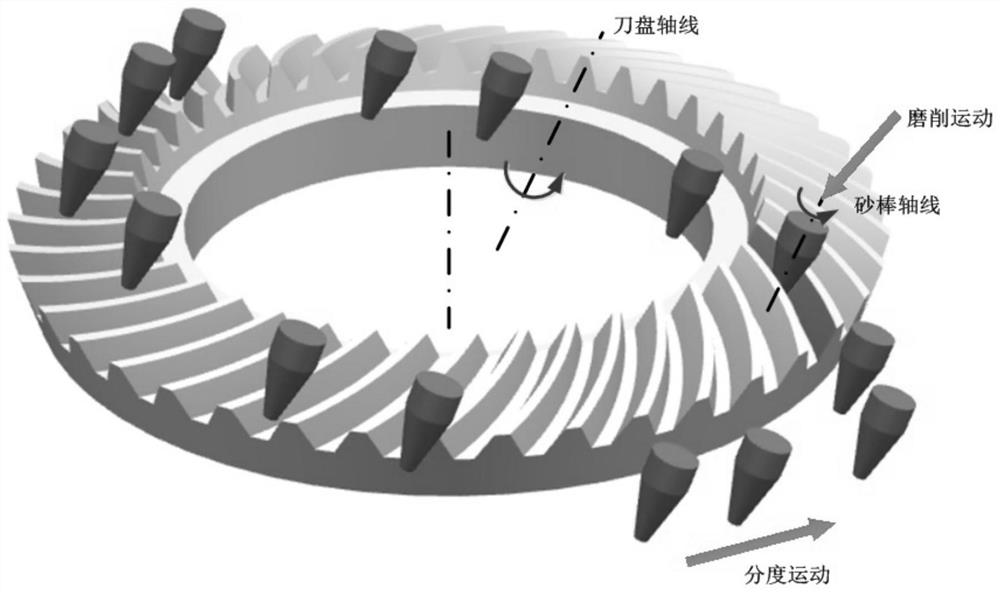

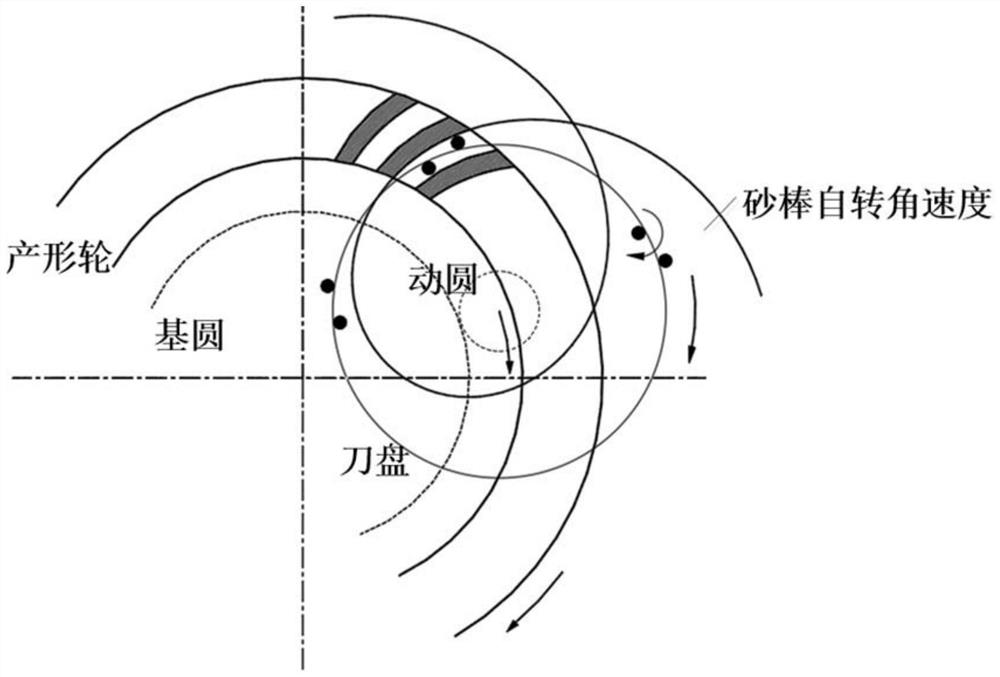

[0026] According to the cycloidal bevel gear continuous indexing grinding method of the present invention, the cycloidal bevel gear is processed by the face hobbing method, see figure 1 , and then replace the knife bar used for face hobbing on the cutterhead with a conical sand bar in situ, the generatrix of the tapered sand bar coincides with the edge line of the knife bar, and the generatrix of the tapered sand bar coincides with the knife bar The normal vectors on the theoretically generated shape surface formed by the blades are the same. After replacing the conical sand rod in situ, the gear grinding parameters are adjusted first, and then the cycloidal bevel gear is continuously indexed and ground by the generatrix of the sand rod.

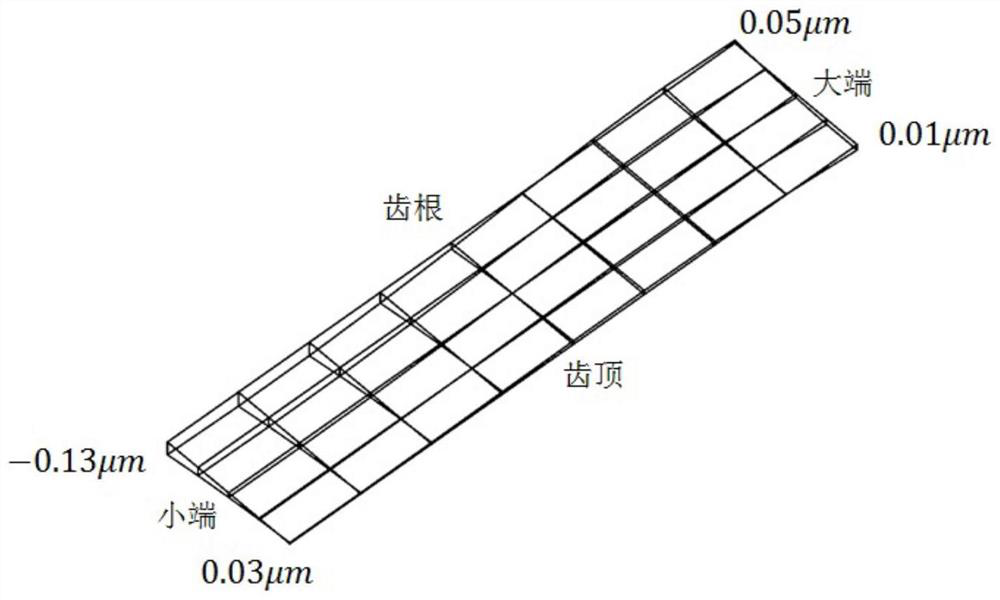

[0027] The generatrix of the conical sand bar is used to replace the blade blade, and the gear grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com