Three-arm workpiece production process and the workpiece produced by this process

A production process and workpiece technology, which is applied to the three-arm workpiece production process and the workpiece field produced by this process, can solve the problems of reducing the production yield of the workpiece, deformation damage, and the final workpiece cannot be effectively matched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 is a kind of three-arm workpiece production process disclosed by the present invention, comprising the following steps:

[0059] S1. Select raw materials and find raw material blocks whose volume and shape can meet the design requirements;

[0060] Use ruler tools such as vernier calipers to select raw materials whose size meets the design requirements;

[0061] Use spectrometers, metallographic microscopes and other detection tools to detect the elemental composition of raw materials, and select raw materials with less non-metallic inclusions and no cracks.

[0062] When selecting raw materials, fully inspecting the raw materials first can effectively improve the yield of the final product and reduce the probability of the final workpiece being unqualified due to raw material problems.

[0063] S2. Heating. Use an intermediate frequency heating furnace to heat the raw materials to a temperature of 450-500 degrees. Keep this temperature until all positions...

Embodiment 2

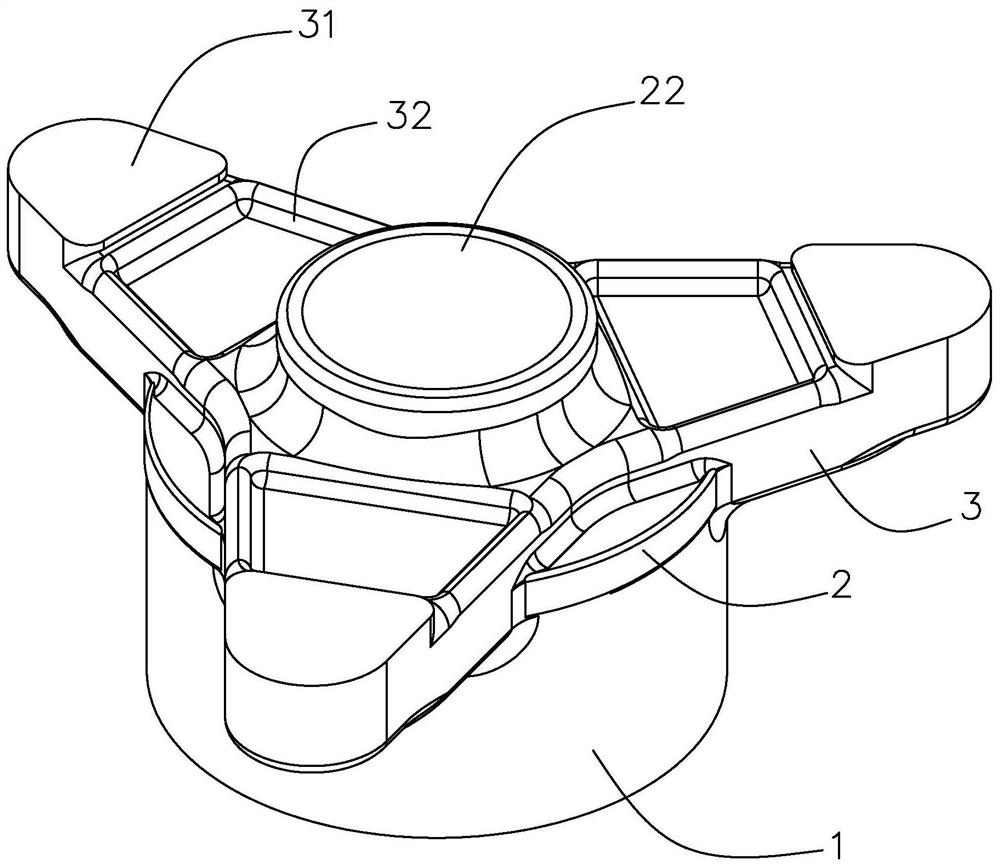

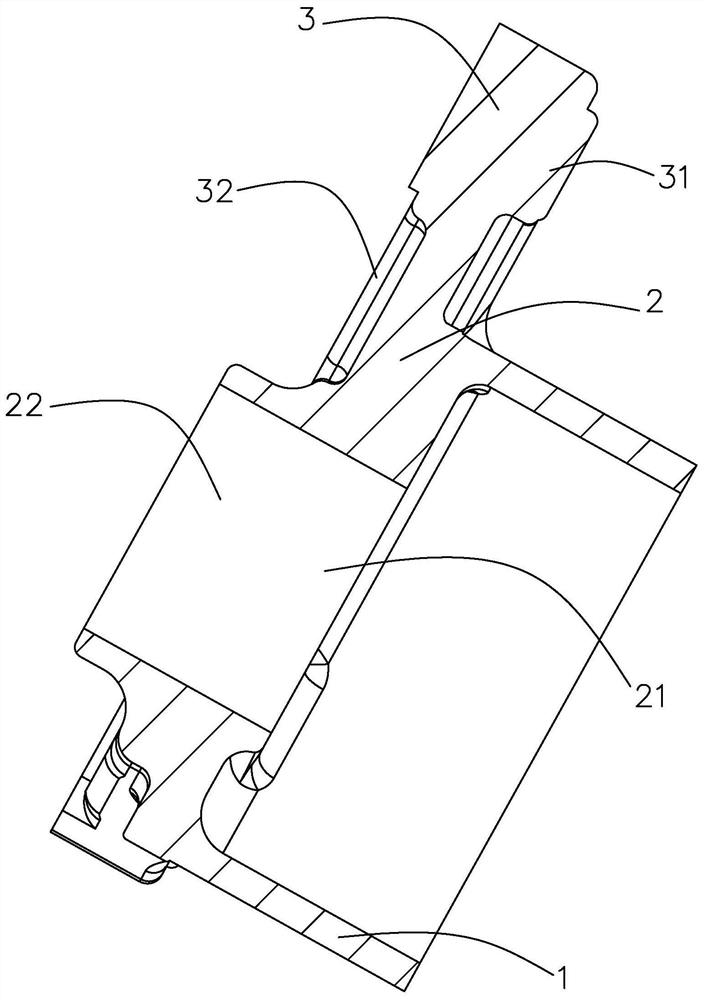

[0085] figure 1 with figure 2 It is a workpiece produced by using the three-arm workpiece production process disclosed in the present invention, and it is characterized in that it includes a cylindrical part 1 and a support part 2 fixedly connected to one end of the cylindrical part 1, and the plane where the support part 2 is located is perpendicular to the cylindrical part 1 central axis setting. Three support arms 3 are fixedly connected to the side wall of the support part 2 , and the three support arms 3 are arranged around the cylindrical part 1 . The surfaces of the three support arms 3 away from the cylindrical portion 1 are fixedly connected with support blocks 31 , and the support blocks 31 are all arranged at the ends of the support arms 3 away from the cylindrical portion 1 . A through hole 21 is opened in the middle of the supporting part 2 , and the diameter of the through hole 21 is smaller than the inner diameter of the cylindrical part 1 . An extension tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com