Graphene heating sheet and preparation method and application thereof

A kind of graphene, heating sheet technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained and illustrated below in conjunction with specific embodiments.

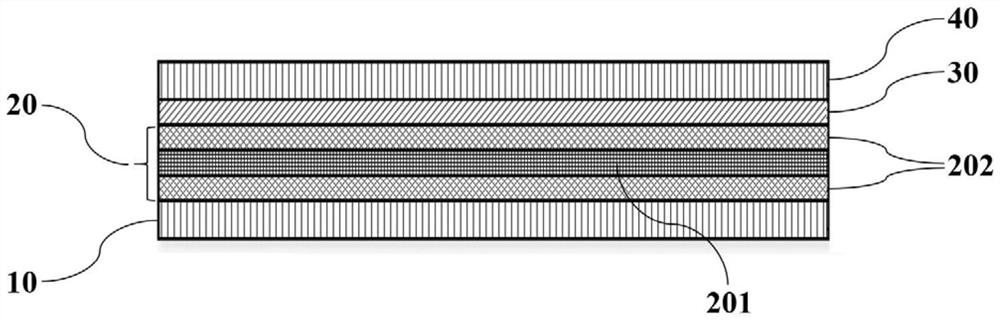

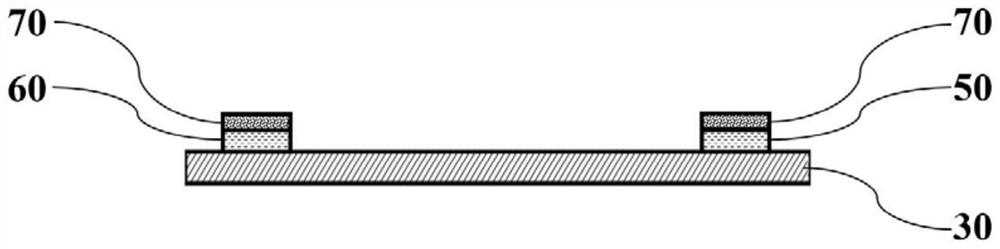

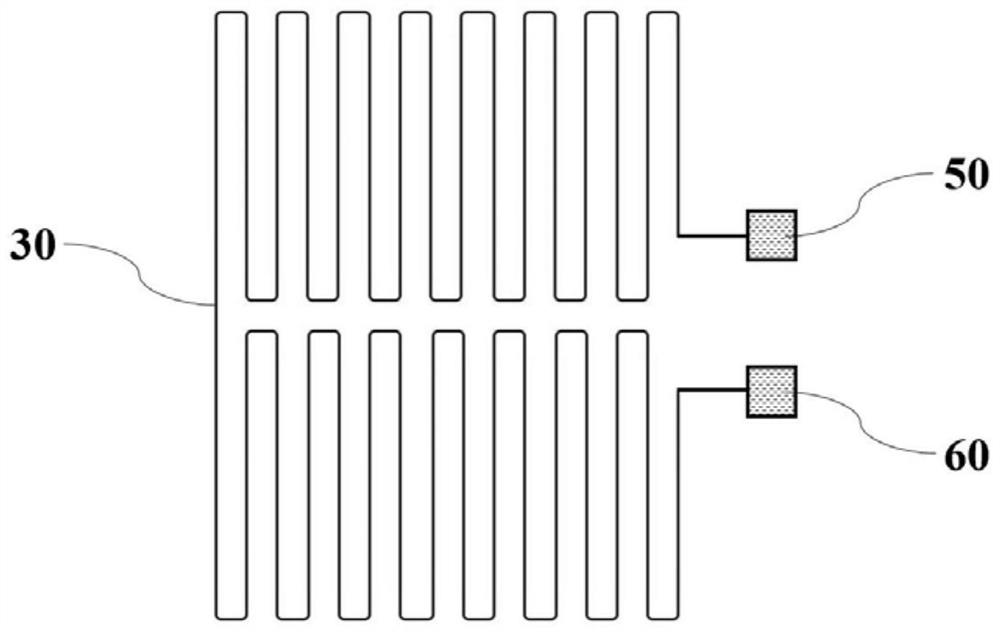

[0031] Such as Figure 1~3 As shown, a graphene heating chip, its composition structure includes a lower insulating layer 10, a heating layer 20, a copper conductive layer 30 and an upper insulating layer 40 arranged sequentially from bottom to top, and also includes a Positive electrode 50 and negative electrode 60; The composition of described heating layer 20 comprises flexible base material layer 201 and the graphene heating layer 202 that is coated on flexible base material layer two sides; The surface of described positive electrode 50 and negative electrode 60 is coated with There is a ceramic powder coating 70 with a positive temperature coefficient thermistor effect; the graphene heating layer 202 is electrically connected to the copper conductive layer 30; the flexible substrate layer 201 is an aramid fiber film; the lower insulating layer 10 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com