Process for preparing N-methyl-1,3-propane diamine through continuous catalytic reaction by using two fixed bed reactors

A fixed-bed reactor and catalytic reaction technology, applied in the preparation of amino compounds, organic compounds, carboxylic acid nitriles, etc., can solve the complex distillation and purification of products, many by-products, and difficult to achieve large-scale industrialization and other problems, to achieve the effect of easy continuous production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

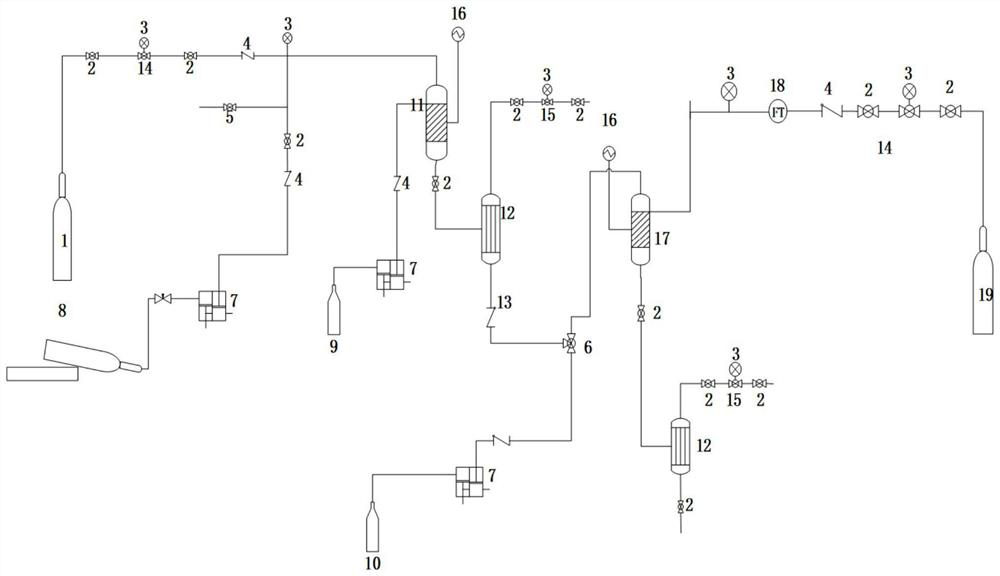

Method used

Image

Examples

Embodiment 1

[0026] (1) Firstly, the reactor 11 and the reactor 17 are filled with catalyst 4A type molecular sieve and Raney-Ni respectively. (2) Open the nitrogen cylinder, purge the whole system, discharge the air, set the pressure on the fixed bed reactor 11 through the nitrogen pressure reducing valve 14: 4MPa, and set the temperature by the temperature controller 16: 35°C. The pressure of the fixed bed reactor 17 is set by the hydrogen cylinder 19 through the pressure reducing valve 14 to the system to set the hydrogen pressure: 4MPa, and the hydrogen flow rate is controlled by the mass flow controller 18, and the temperature is set by the temperature controller 16 to 65°C. (3) Use two double-plunger micropumps 7 to transport monomethylamine ethanol solution (40%) and acrylonitrile (99%) to the fixed-bed reactor filled with 4A molecular sieve catalyst at a molar ratio of 1.1:1 11 reactions, at a space velocity of 0.8h -1 Under certain conditions, continuous reaction makes the reacti...

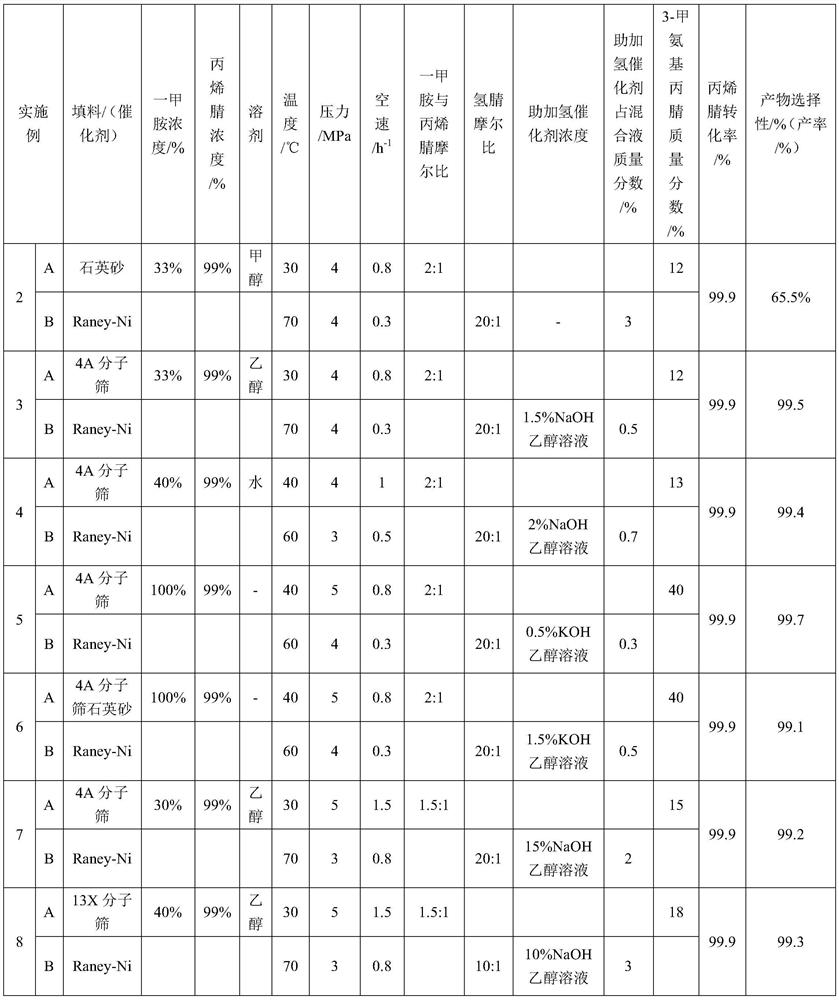

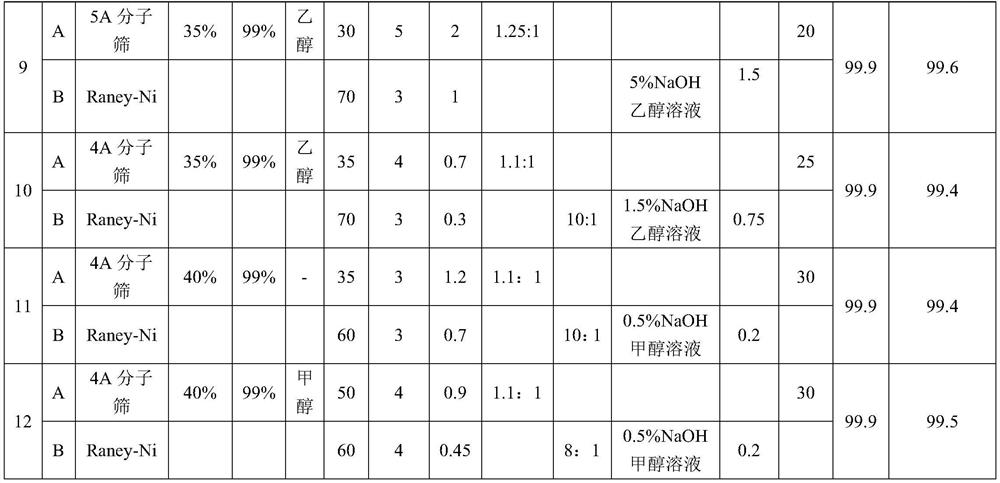

Embodiment 2-12

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com