Single crystal copper two-body abrasive wear simulation method

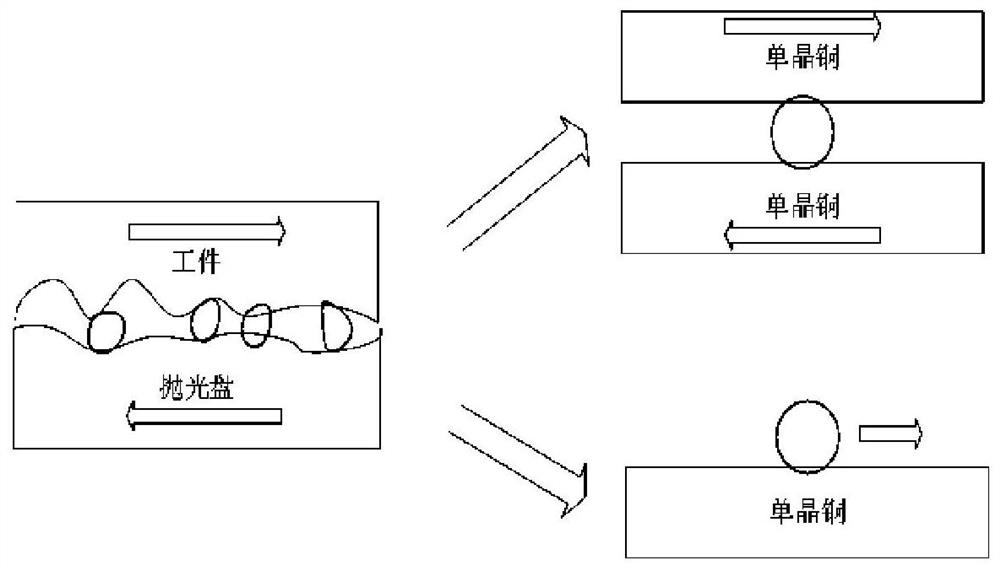

A kind of technology of abrasive wear and simulation method, which is applied in the field of simulation simulation calculation, can solve the problems of extremely complicated contact mode, insufficient understanding of the essence, difficulty in control and observation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

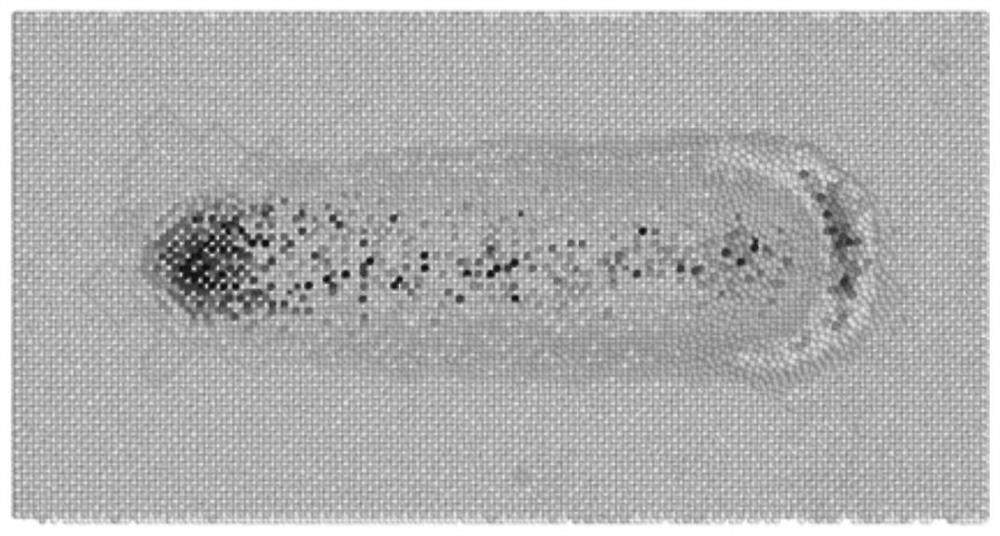

Examples

Embodiment

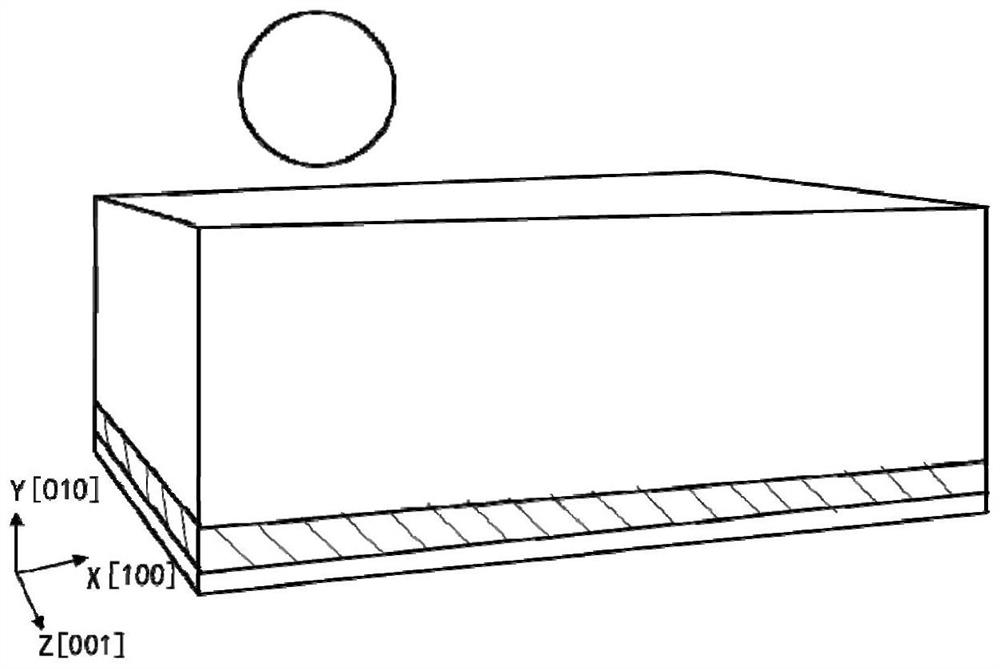

[0035] according to figure 2 , using Lammps software to establish a molecular dynamics model of single-crystal copper two-body abrasive wear, the size of the molecular dynamics model is 28.92nm×10.85nm×14.80nm, and the number of atoms is 400140.

[0036] The single crystal copper matrix model is divided into fixed layer, constant temperature layer and Newton layer from bottom to top, and a space coordinate system is established. Periodic boundary conditions are used in the X and Z directions, and fixed boundary conditions are used in the Y direction. The EAM potential is used to describe the interaction between copper atoms, the Morse potential is used to describe the relationship between copper atoms and carbon atoms, and the binding energy coefficient D 0 = 0.087eV, potential energy curve gradient coefficient α = 51.41nm, atomic distance γ 0 = 0.205nm.

[0037] Set the load to 40-100nN, set the abrasive sliding velocity to 50-200m / s, use the conjugate gradient method to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com