Method for establishing electromagnetic stirring parameters of secondary cooling area of plate blank

A technology of electromagnetic stirring and secondary cooling, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of large differences in conclusions and large differences in stirring effects, etc. The effect of improving the internal quality of the billet and increasing the stirring intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

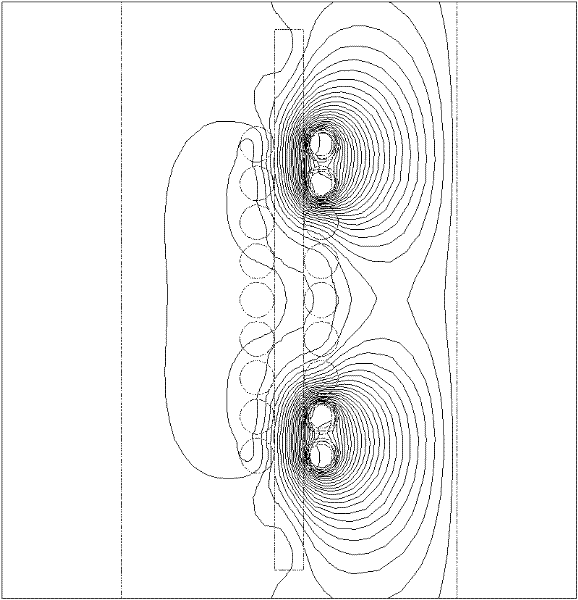

[0048] The method of the invention is used to calculate the magnetic field distribution generated by different electromagnetic stirrer arrangements, and to determine a reasonable electromagnetic stirrer arrangement.

[0049] The steel grade is 45# high carbon steel, which is implemented on the electromagnetic stirrer in the secondary cooling zone of the slab casting machine with a size of 200×1450 mm. The current is 400A, the frequency is 5Hz, the drawing speed is 1.4m / min, and the superheat degree is 18℃.

[0050] Calculate the relative permeability of air, rolls, coils, shells, molten steel and water in =1, the resistivity is 1×10 20 Ω m, 7.0×10 -7 Ω m, 1.67×10 -8 Ω m, 7.5×10 -7 Ω m, 150×10 -8 Ω m, 670 Ω ·m. The convergence monitoring amount of the electromagnetic field is less than 10 -6 , the calculated residual is less than 10 -4 .

[0051] The assumptions are:

[0052] 1. The molten steel is an incompressible conductive fluid, and the density, viscos...

Embodiment 2

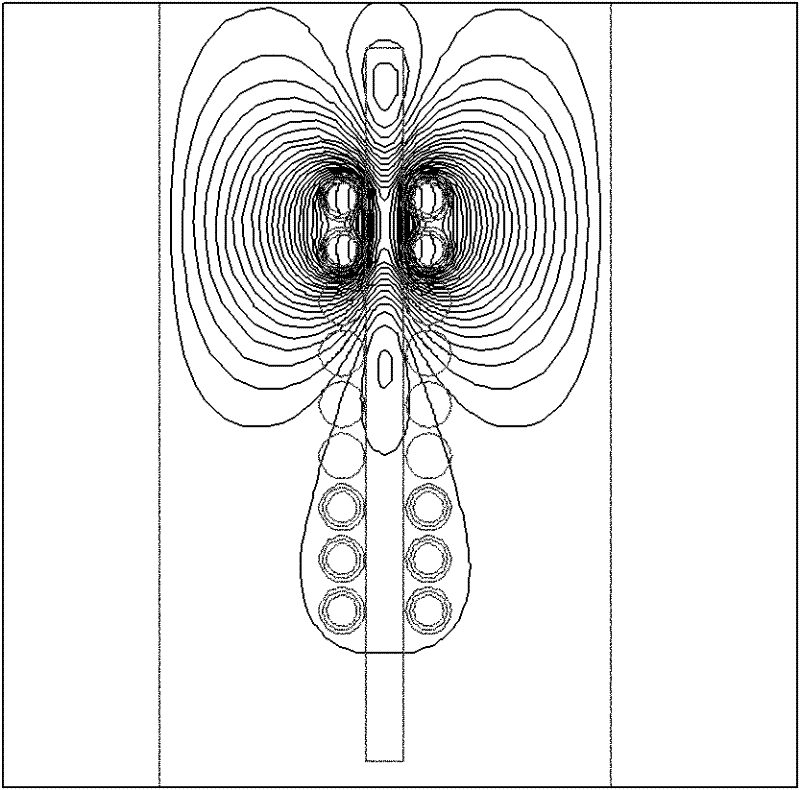

[0063] The method of the invention is used to calculate the magnetic field distribution generated by different stirring current directions, and to determine a reasonable stirring current direction.

[0064] The steel grade is 45# high carbon steel, which is implemented on the electromagnetic stirrer in the secondary cooling zone of the slab casting machine with a size of 200×1450 mm. The current is 400A, the frequency is 5Hz, the drawing speed is 1.4m / min, and the superheat degree is 18℃.

[0065] Calculate the relative permeability of air, rolls, coils, shells, molten steel and water in =1, the resistivity is 1×10 20 Ω m, 7.0×10 -7 Ω m, 1.67×10 -8 Ω m, 7.5×10 -7 Ω m, 150×10 -8 Ω m, 670 Ω ·m. The convergence monitoring amount of the electromagnetic field is less than 10 -6 , the calculated residual is less than 10 -4 .

[0066] The assumptions are:

[0067] 1. The molten steel is an incompressible conductive fluid, and the density, viscosity coefficient ...

Embodiment 3

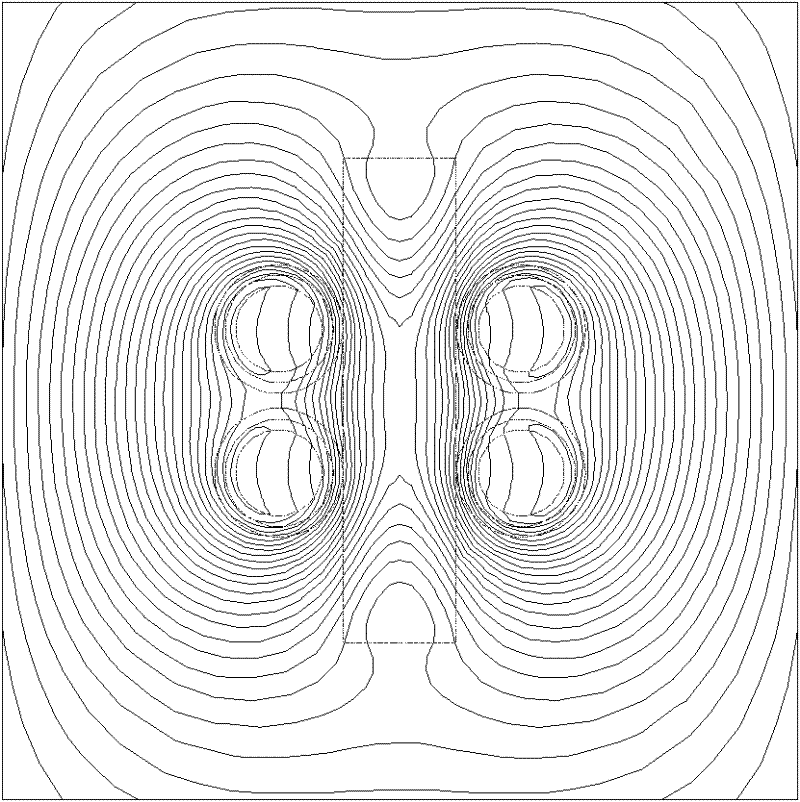

[0077] The agitator adopts the opposite arrangement, and the stirring current selects the opposite current to verify the implementation effect.

[0078] The steel grade is 45# high carbon steel, which is implemented on the electromagnetic stirrer in the secondary cooling zone of the slab casting machine of 200×1450 mm. The stirrer is located 4m below the meniscus, and the section size of the slab is 200×1380 mm. The current intensity is 400A, the frequency is 5Hz, the drawing speed is 1.4m / min, and the superheat degree is 18℃.

[0079] The stirrer is arranged oppositely, and the direction of stirring current selects an opposite current, and 8 furnaces are continuously produced, and the production runs smoothly. The dendrite inspection results show that the center of the billet is loose, subcutaneous cracks, core cracks, shrinkage holes and subcutaneous bubbles are all zero. grade, the central segregation is C0.5 grade, the average equiaxed grain rate is over 50%, and the inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com