Preparation method of voltage stabilizing diode with stable breakdown voltage

A voltage-stabilizing diode and breakdown voltage technology, which is applied in the field of diodes, can solve problems such as large changes in impurity concentration distribution and impact on breakdown voltage, and achieve reduced breakdown voltage changes, improved breakdown voltage stability, and good process compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

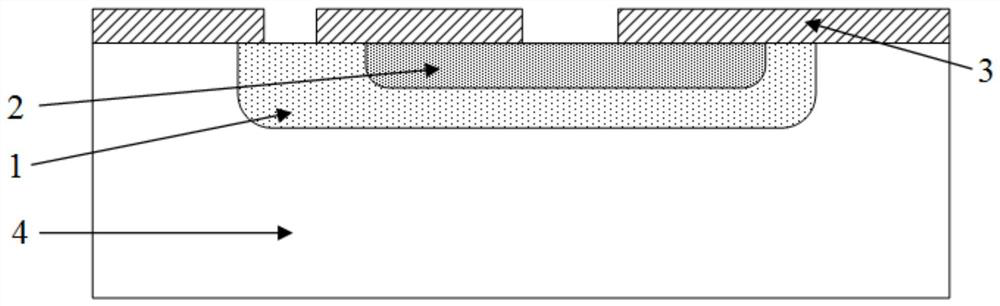

[0049] The Zener diode structure formed by the process method of the present invention is as follows:

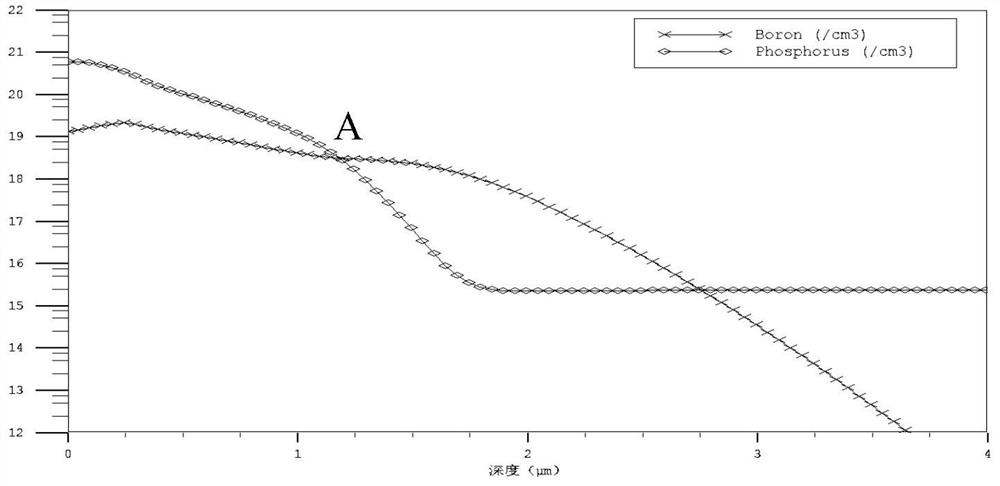

[0050] 1. The junction depth of the P-type region 1 of the Zener diode is 2.7 μm, and the doping concentration is 1.0E19cm -3 , the junction depth of the high-concentration N-type region 2 is 1.0 μm; the doping concentration is 1.0E20cm -3 ;

[0051] 2. Under the same breakdown voltage condition of the Zener diode, the standard deviation of the breakdown voltage of the Zener diode formed by the process method of the present invention is 0.02376, the standard deviation of the breakdown voltage of the traditionally formed Zener diode is 0.04967, and the voltage stabilizer formed by the new process method Diode breakdown voltage stability is higher than traditional technology.

[0052] This structure can be realized by the following methods:

[0053] 1. At a temperature of 950°C, a 100nm silicon dioxide layer 3 is grown on the silicon surface of the N-type substrate through ...

Embodiment example 2

[0061] The Zener diode structure formed by the process method of the present invention is as follows:

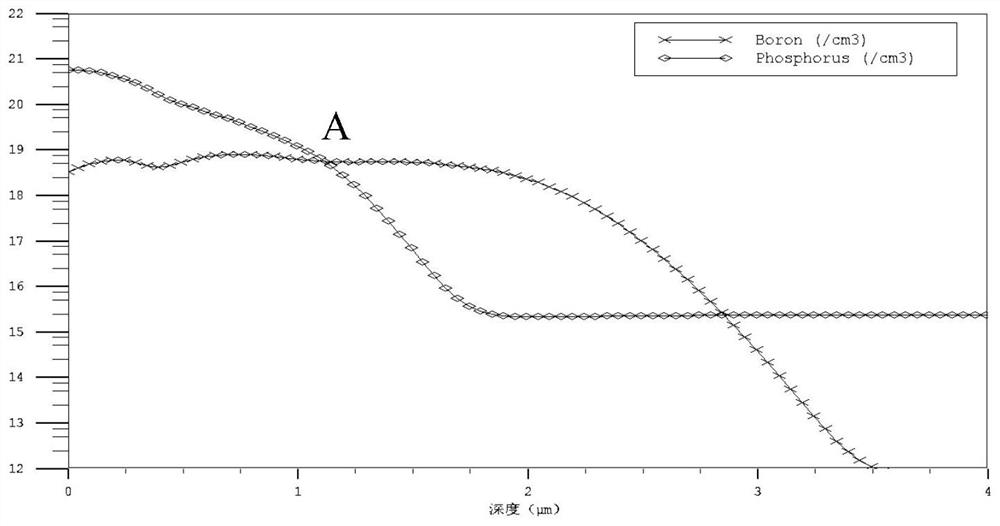

[0062] 1. The junction depth of the P-type region 1 of the Zener diode is 2.0 μm, and the doping concentration is 1.0E18cm -3 , the junction depth of the high-concentration N-type region 2 is 1.2 μm; the doping concentration is 1.0E20cm -3 ;

[0063] 2. Under the same breakdown voltage condition of the Zener diode, the standard deviation of the breakdown voltage of the Zener diode formed by the process method of the present invention is 0.03671, the standard deviation of the breakdown voltage of the traditionally formed Zener diode is 0.06053, and the voltage stabilizer formed by the new process method is 0.03671. Diode breakdown voltage stability is higher than traditional technology.

[0064] This structure can be realized by the following methods:

[0065] 1. At a temperature of 950°C, a 100nm silicon dioxide layer 3 is grown on the silicon surface of the N-type substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com