A kind of varactor diode die and its preparation method

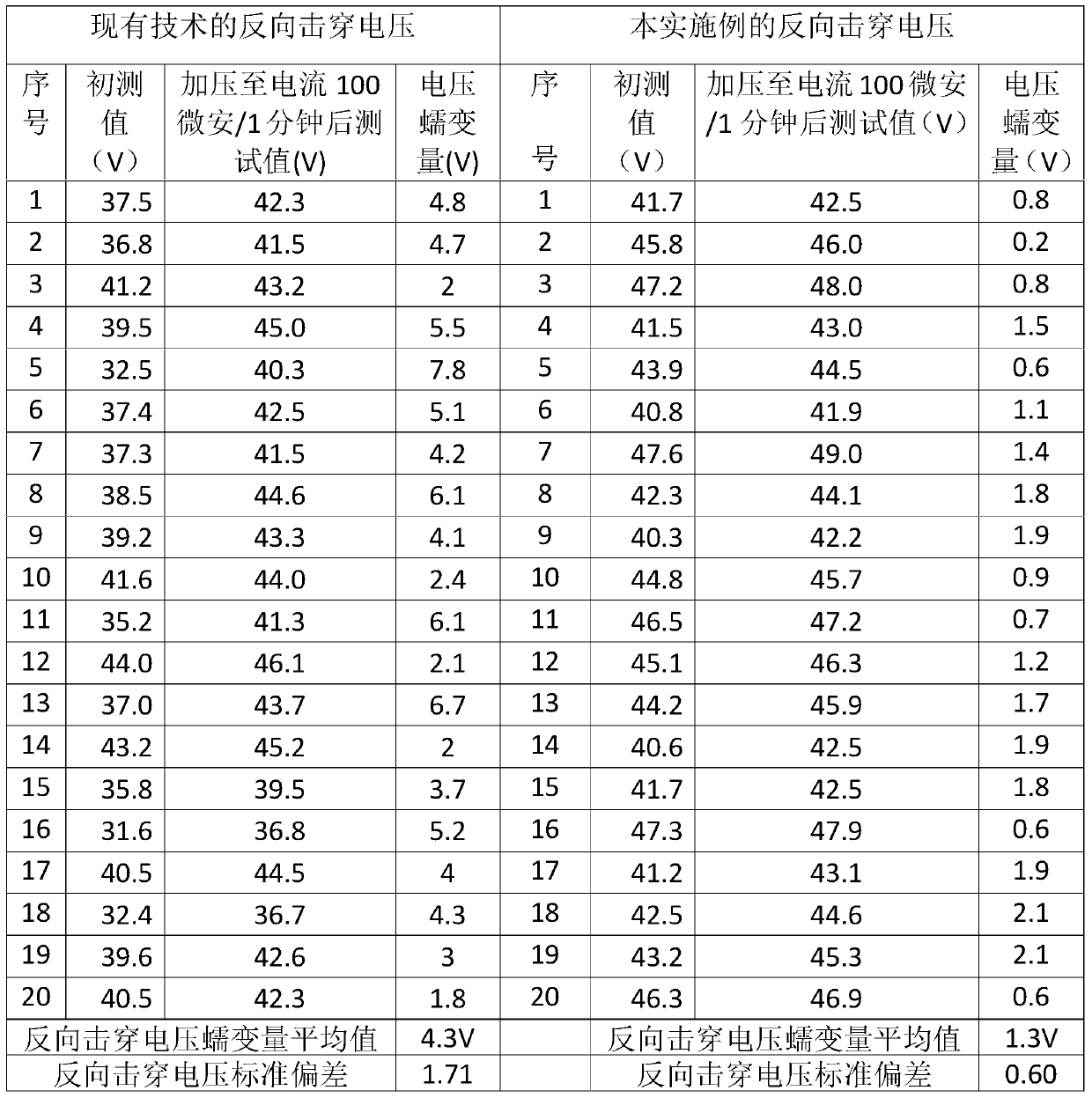

A technology of varactor diodes and tube cores, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as surface impurity contamination, ineffective fixation, yield and electrical parameters, etc., to achieve reverse The effect of reducing leakage current value and dispersion, improving breakdown voltage stability, and improving high temperature performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

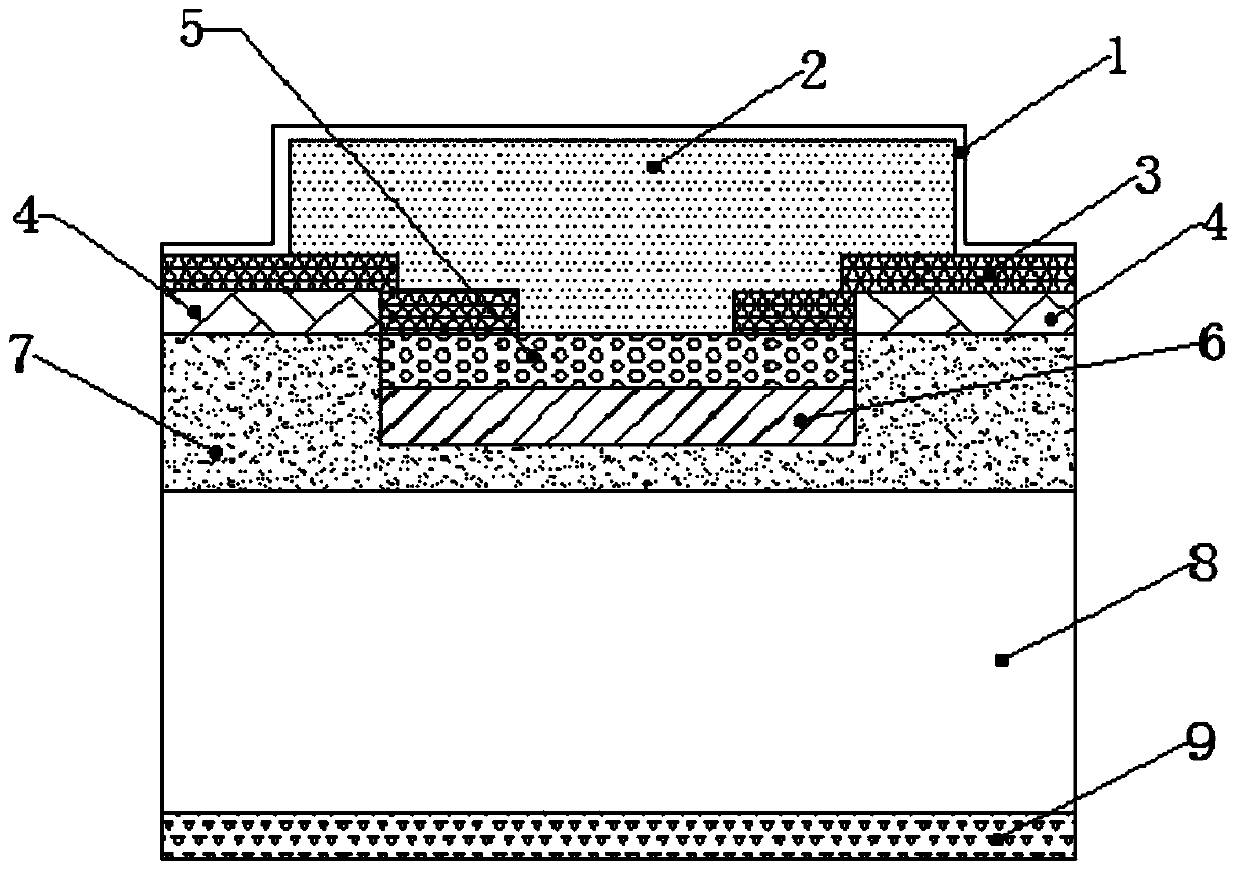

[0088] Such as figure 1 As shown, the present invention provides two layers of passivation layers on the tube core, the first passivation layer 3 is located between the PN junction and the silver stage electrode 2, but does not completely block the contact between the PN junction and the silver stage electrode 2, and the second passivation layer 3 The second passivation layer 1 covers the uppermost layer of the die. The central part of the PN junction is in direct contact with the silver platform electrode 2; the second passivation layer 1 covers the silver platform electrode 2 and the exposed first passivation layer 3.

[0089] The PN junction is composed of an epitaxial layer 7, a phosphorus diffusion layer 6 and a boron diffusion layer 5, the phosphorus diffusion layer 6 and the boron diffusion layer 5 are located in the well structure of the epitaxial layer 7, wherein the phosphorus diffusion layer 6 is located at the bottom of the well structure, The boron diffusion laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com