Lithium-philic alloy modification layer, composite lithium negative electrode material, and preparation method and application of material

A negative electrode material, lithium alloy technology, applied in nanotechnology for materials and surface science, negative electrodes, battery electrodes, etc., can solve the problems of electrode volume expansion, complex preparation methods, lithium dendrite growth, etc., to achieve extended cycle Effects of longevity, rate performance improvement, and high affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment 1 provides a lithium-philic alloy modification layer, a composite lithium negative electrode material and a preparation method thereof, specifically comprising the following steps:

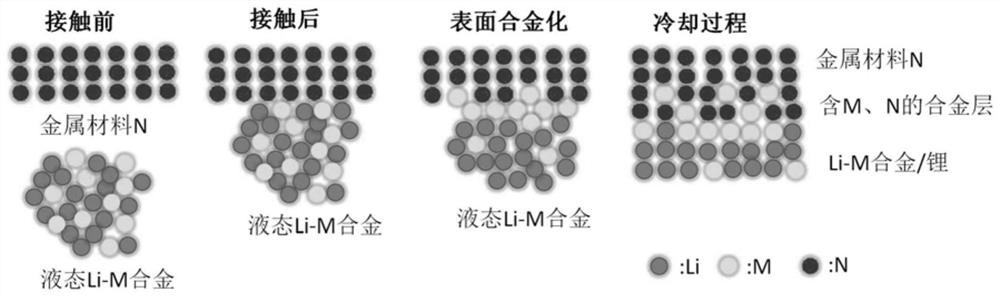

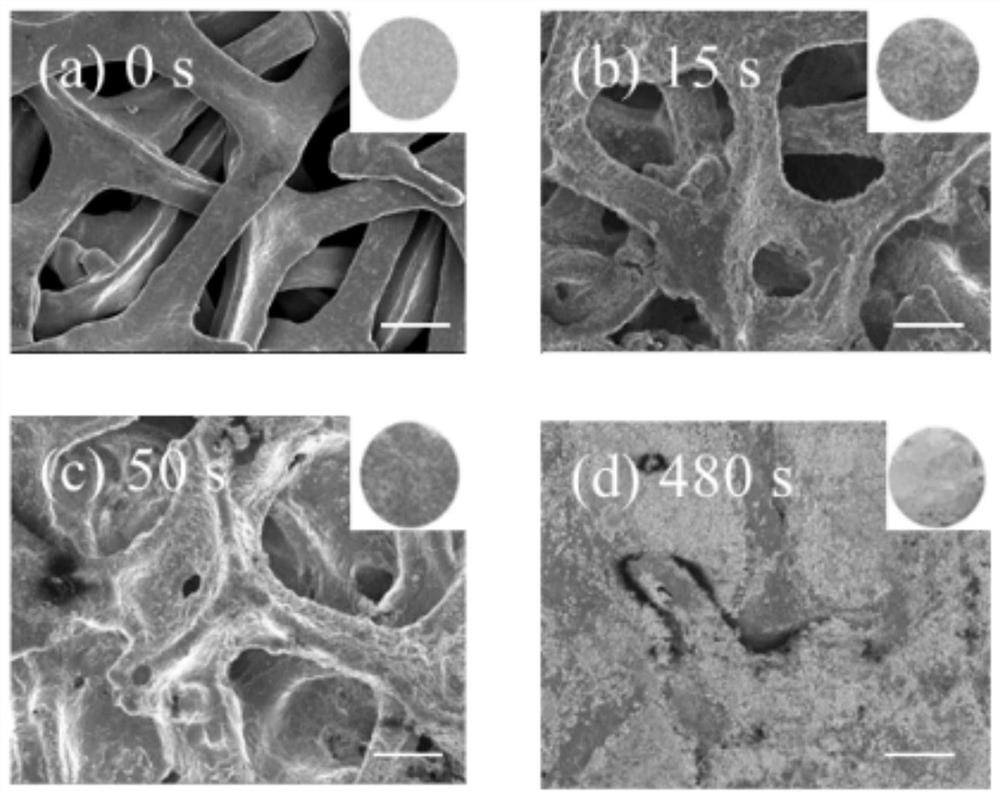

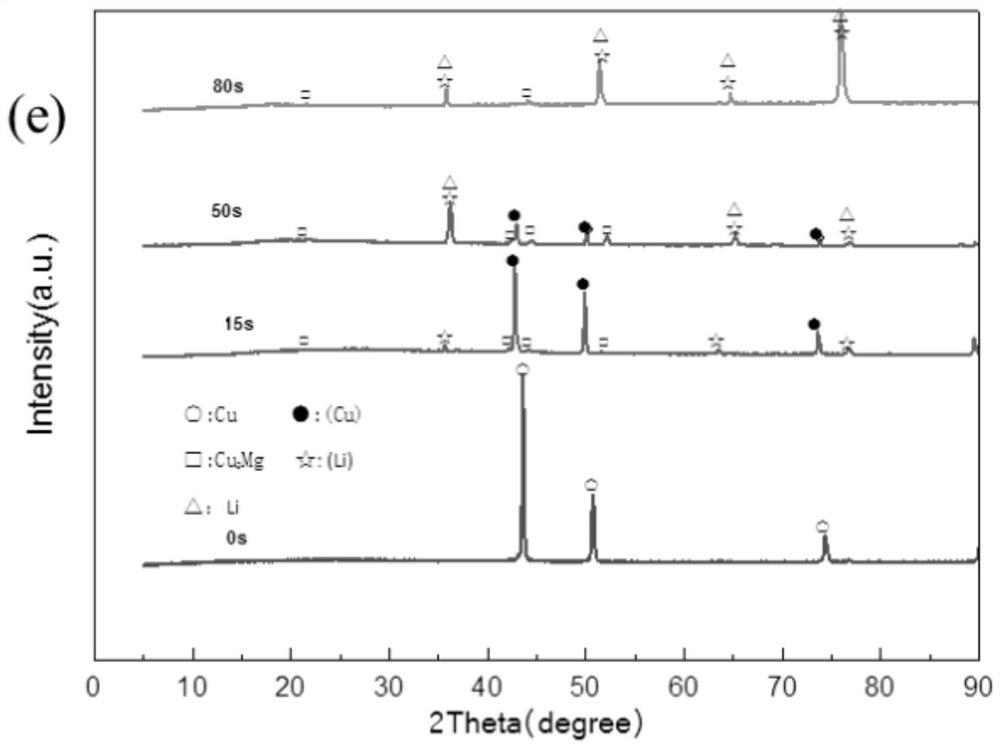

[0035] In an external environment with a dew point of -50°C and an oxygen content of less than 10ppm, metal lithium is placed in a stainless steel crucible and placed on a heating platform with a temperature of 400°C to make the metal lithium into a molten state; then metal magnesium ( Mg) is added to molten metal lithium to form a molten lithium alloy; finally, the obtained molten lithium alloy is contacted with the surface of the foamed copper cavity structure, and it is cooled to room temperature within 2 minutes to obtain a metal-containing material. A three-layer structure of Cu skeleton layer, Mg-Cu lithium-philic alloy modification layer and Li-Mg lithium alloy / metal lithium layer, a solid composite lithium anode material containing at least three components, and a sch...

Embodiment 2

[0037] This embodiment 2 provides a lithium-philic alloy modification layer, a composite lithium negative electrode material and a preparation method thereof. The difference from embodiment 1 is only that the foamed copper cavity structure material in embodiment 1 is replaced with copper foil, and the remaining parameters are the same.

Embodiment 3

[0039]This embodiment 3 provides a lithium-philic alloy modification layer, a composite lithium negative electrode material and a preparation method thereof. The difference from the embodiment 1 is only that the foamed copper cavity structure material in the embodiment 1 is replaced by a copper wire network, and the rest The parameters are all the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com