Reinforced end mill for machining side wall

A technology for end mills and strengthening components, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of easy breakage at the connection between the milling cutter and the shank, low service life, and easy damage to the milling cutter. The phenomenon of knife dropping, improving the service life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

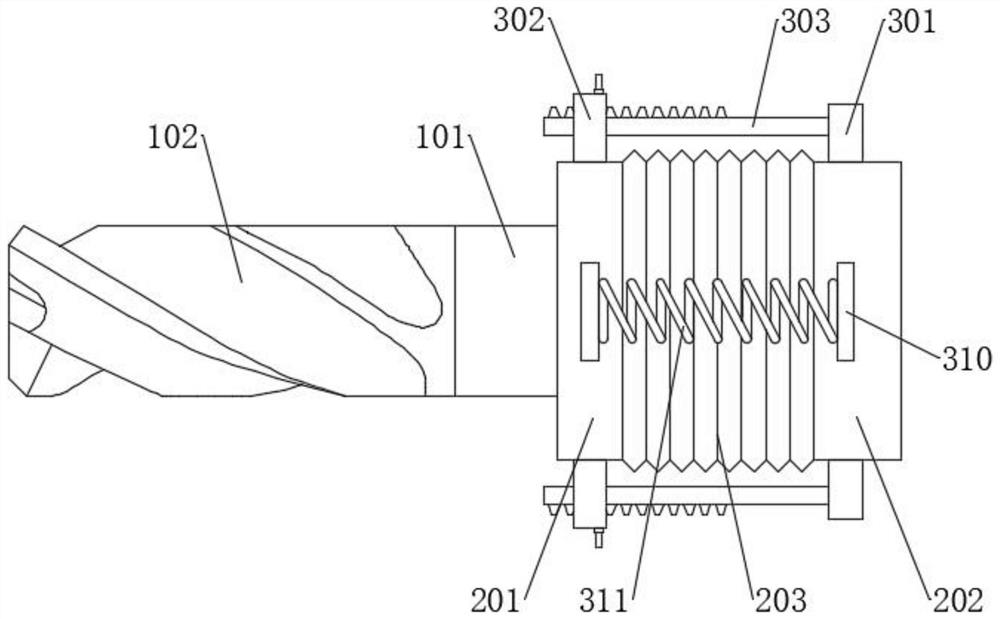

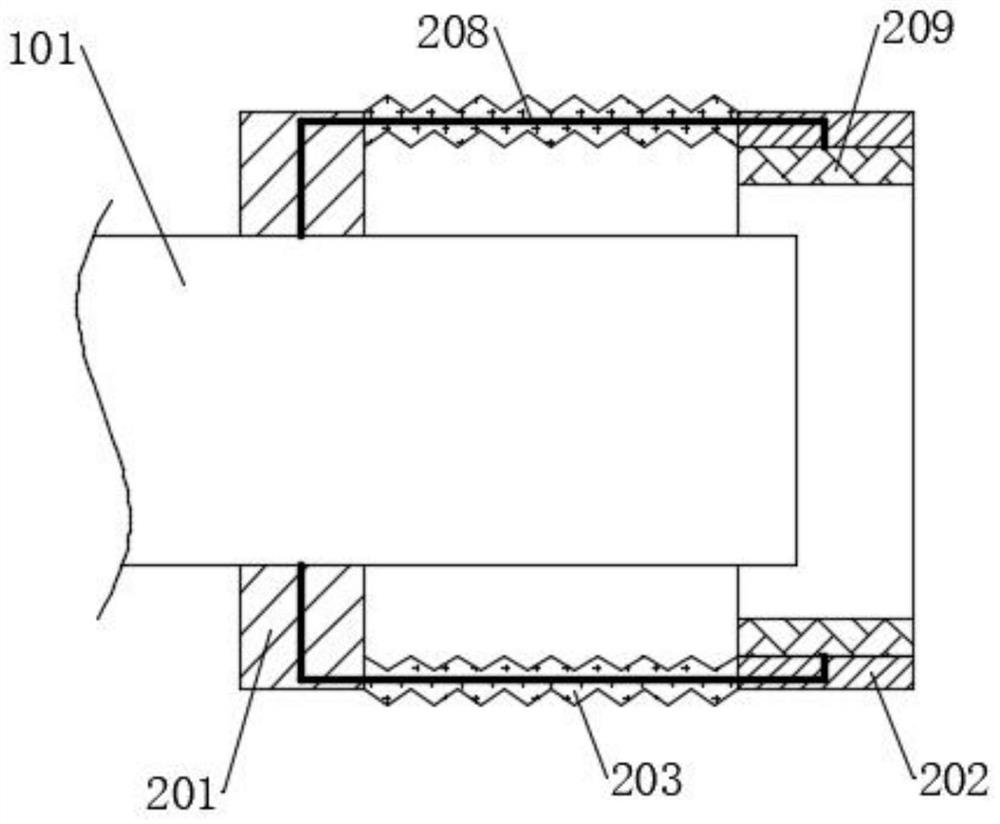

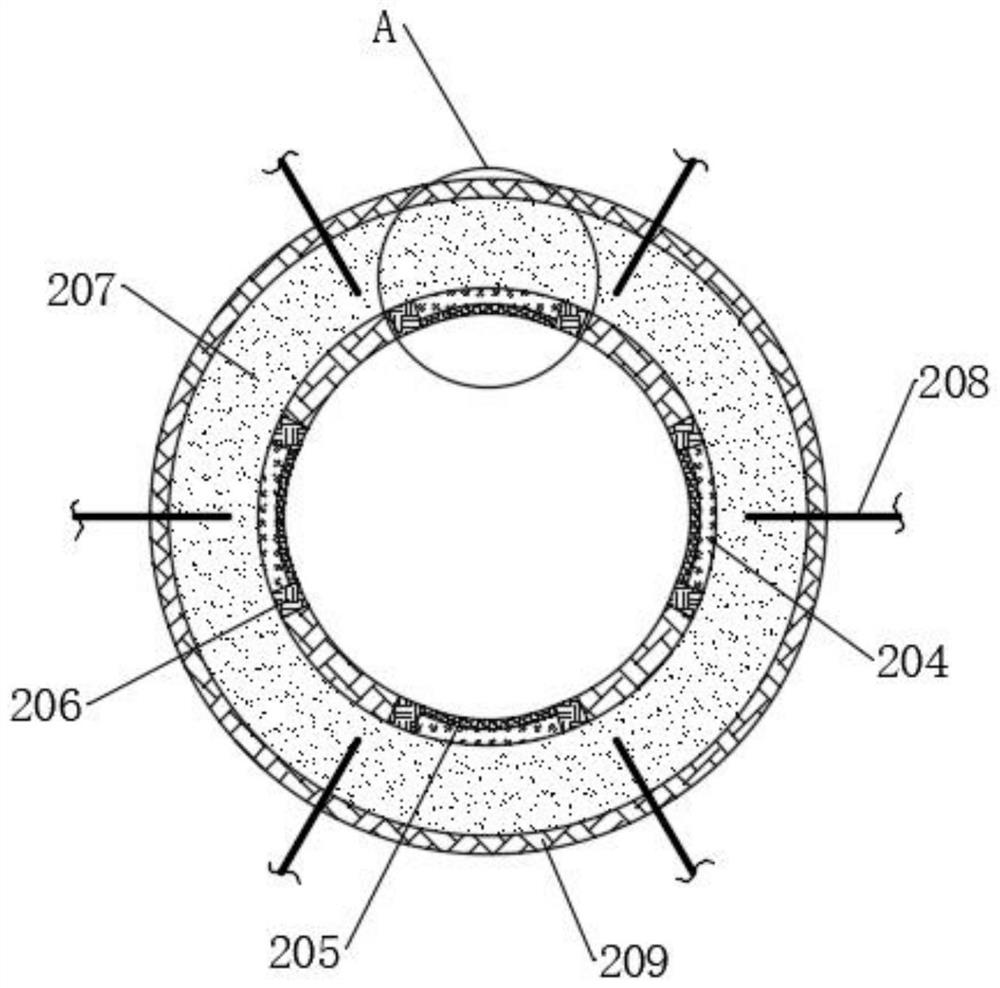

[0033] see Figure 1-5 , a reinforced end mill for processing side walls, including a cutter body, the cutter body includes a shank 101, a blade 102, the blade 102 is fixedly connected to one end of the shank 101, and a self-reinforcing component is arranged on the outer wall of the shank 101 , the self-reinforcing assembly includes a fixed collar 201 and a movable support ring 202. The fixed collar 201 is fixedly sleeved on the outer wall of the blade 102, and the movable support ring 202 is movably sleeved on the end of the handle 101 away from the blade 102. The fixed sleeve The connecting film cover 203 is connected between the ring 201 and the movable support ring 202, and the connecting film cover 203 is arranged in a folded shape, and the connecting film cover 203 is made of a flexible material, so that the connecting film cover 203 can be contracted and folded, and then the movable support The ring 202 can move towards the direction close to the fixed collar 201, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com