Automatic polishing equipment for steel sheets

A technology for automatic polishing and steel sheeting, which can be used in grinding/polishing equipment, metal processing equipment, machine tools with surface polishing, etc., and can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides an automatic polishing equipment for steel sheets, which is used to solve the technical problem of inconvenient operation in the prior art when polishing steel sheets manually. Specifically, when manually polishing the steel sheet, the labor intensity of the operator is high, the output is low, and the polishing quality cannot be guaranteed, and the labor cost is large, and the dust generated during the polishing process will cause serious damage to the health of the operator. Great threat.

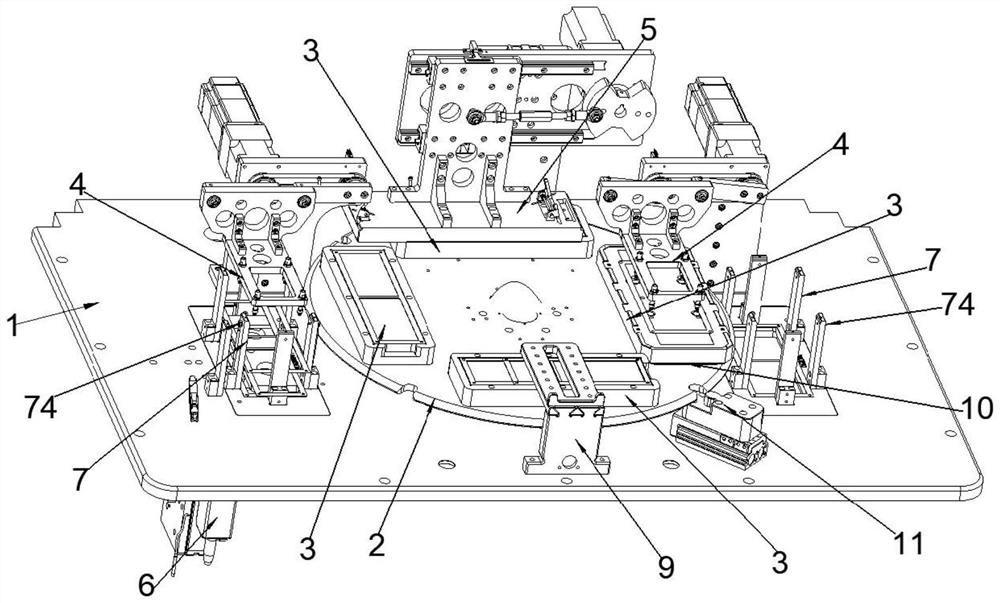

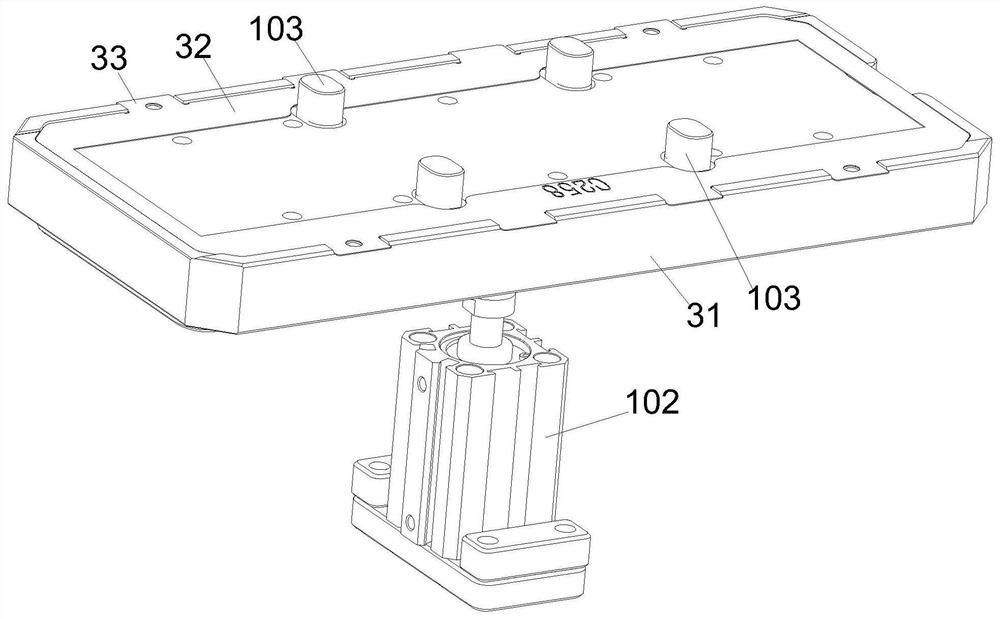

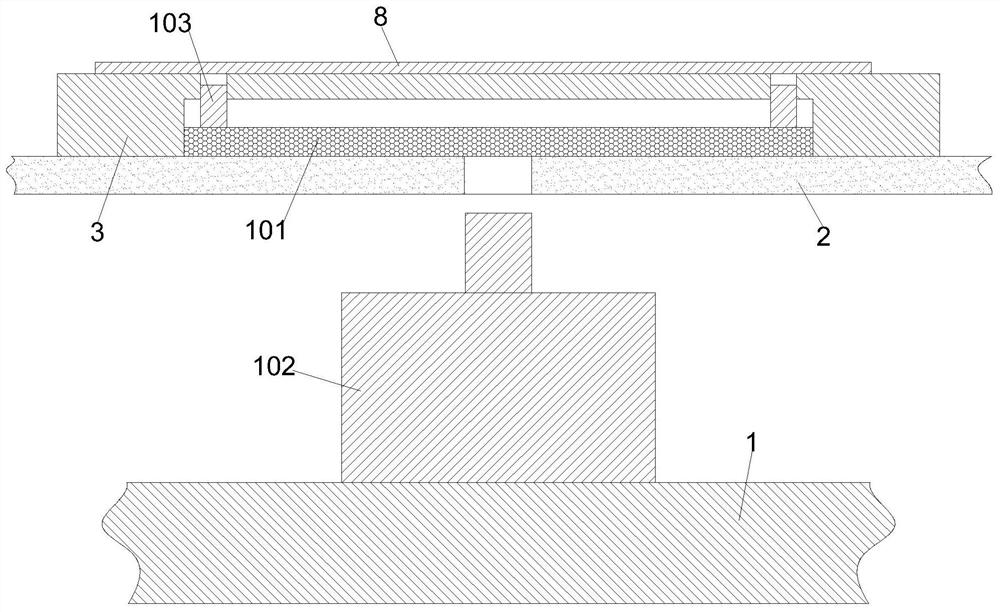

[0053] The steel sheet automatic polishing equipment provided in this embodiment includes a machine 1 , a transfer mechanism, a transport mechanism 4 , a controller, a polishing mechanism 5 and a material ejection mechanism 6 . As a best implementation mode of this embodiment, the transfer mechanism in this embodiment is a turntable 2 , and the above-mentioned transport mechanism 4 and polishing mechanism 5 are both arranged around the turntable 2 . Of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com