Sponge coke and vacuum residue modified high-ductility concrete and preparation method thereof

A technology of high ductility concrete and decompression residue oil, applied in the field of fiber concrete, to achieve the effect of improving ultimate tensile strength and tensile strain, not easy to wear, and reducing the probability of being pulled out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

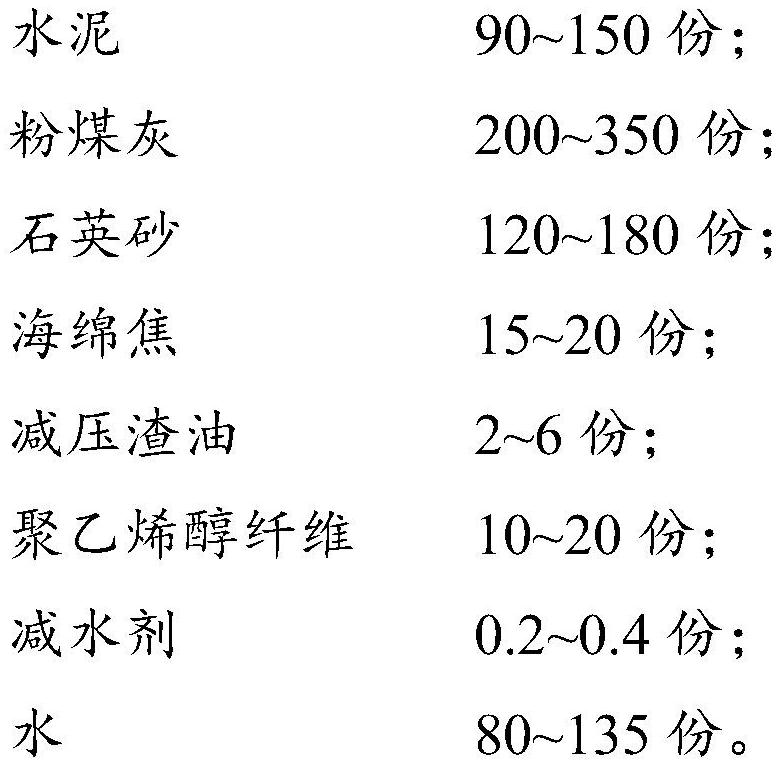

[0036] The present invention provides the preparation method of high-derivative concrete modified above the above-mentioned sponge coke and decompression residue, including the following steps:

[0037] (1) Comparative reduced pressure residue is heated with sponge to obtain a mixture of the plus;

[0038] (2) Stirring water, cement, fly ash, quartz sand and water reducer, and obtain premixed liquid;

[0039] (3) Mix the premixed liquid with an additive mixture, polyvinyl alcohol fibers, to obtain a high-profile concrete modified by sponge coke and decompression residue;

[0040] The steps (1), (2) have no time order limit.

[0041]The discollection residue is booled with a sponge to obtain a mixture of an extension. In the present invention, the temperature of the heating mixing is preferably 140 to 160 ° C, more preferably from 145 to 155 ° C. The present invention preferably heats the reduced pressure residue, and then adds a sponge mixing into the heat and reduction residue. I...

Embodiment 1

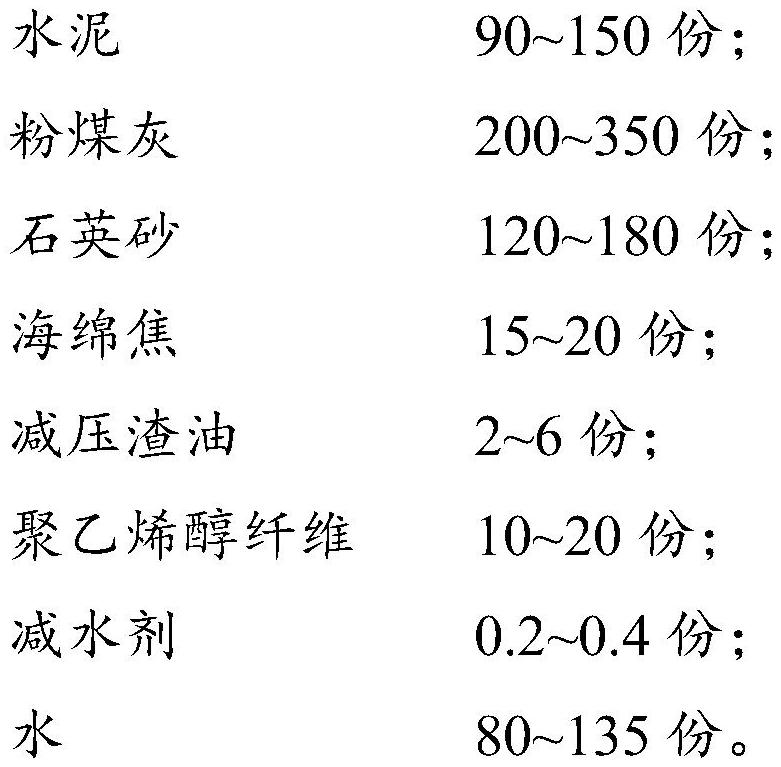

[0047] A sponge coke and decompression residue modified hypervasive concrete, prepared from the following mass of raw materials:

[0048]

[0049] Among them, the particle size of the fly ash is 1 to 100 μm, the particle size of the quartz sand is 0.5 to 2 mm, the particle size of the sponge is ≤ 1 mm; the polyvinyl alcohol fibers have a diameter of 14 to 26 μm, and the length is 6 to 12 mm.

[0050] The viscosity of the reduced pressure residue is 400mm 2 / S, the boiling point is 550 ° C, and the glue content in the decompression residue is 46%.

[0051] The preparation method is as follows:

[0052] (1) Add 90 cement, 200 pieces of fly ash, 120 pieces of stone sand into the stirring pan, stir well;

[0053] (2) Incorporating 0.2 parts water reduction into 80 parts of water, stir well;

[0054] (3) The liquid in step (2) is added to the stirring pan to continue stirring until the slurry flow spread reaches 230 mm to obtain a premixed liquid;

[0055] (4) 2 parts of decompressi...

Embodiment 2

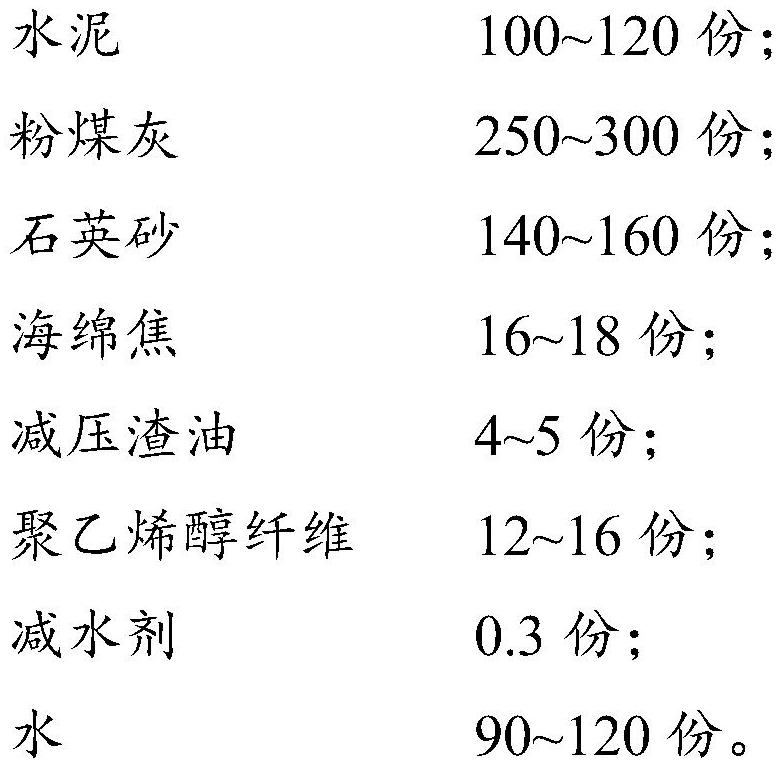

[0059] A sponge coke and decompression residue modified hypervasive concrete, prepared from the following mass of raw materials:

[0060]

[0061] Among them, the particle size of the fly ash is 1 to 100 μm, the particle size of the quartz sand is 0.5 to 2 mm, the particle size of the sponge is ≤ 1 mm; the polyvinyl alcohol fibers have a diameter of 14 to 26 μm, and the length is 6 to 12 mm.

[0062] The viscosity of the reduced pressure residue is 450mm 2 / S, the boiling point is 550 ° C, and the glue content in the decompression residue is 48%.

[0063] The preparation method is as follows:

[0064] (1) Add 110 cement, 260 pieces of fly ash, 150 pieces of stone sand into the stirring pan, stir well;

[0065] (2) In 100 parts of water, 0.3 parts of water reduction agent is mixed into 100 parts of water, stir well;

[0066] (3) The liquid in step (2) is added to the stirring pan to continue stirring until the slurry flow spread reaches 230 mm;

[0067] (4) 4 parts of decompress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com