Sodium fusidate novel crystal form and preparation method and application thereof

A technology for sodium fusidate and fusidic acid is applied in the field of drug crystals, can solve problems such as poor fluidity of sodium fusidate, and achieve the effects of good fluidity, environmental friendliness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

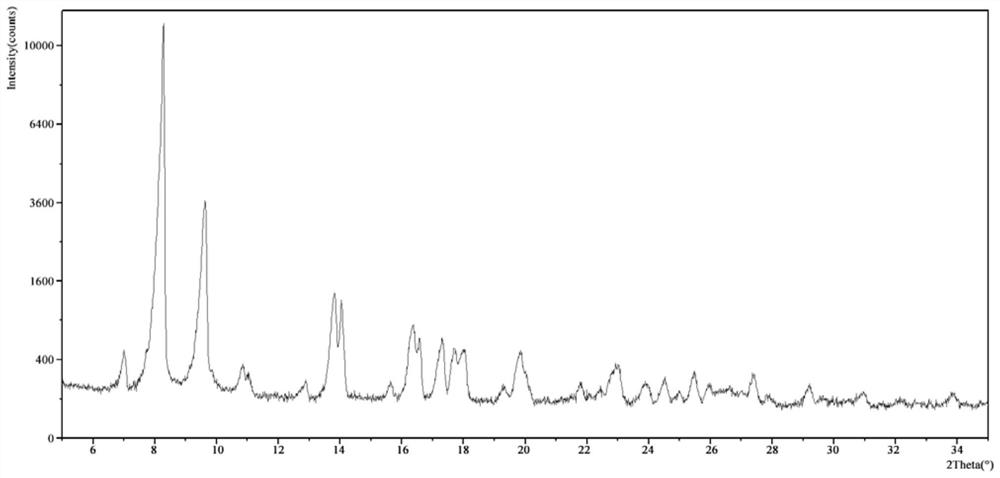

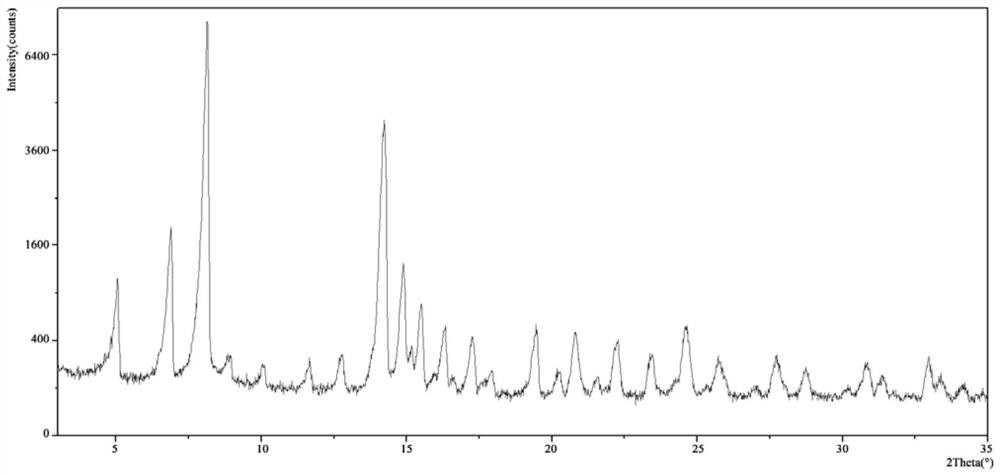

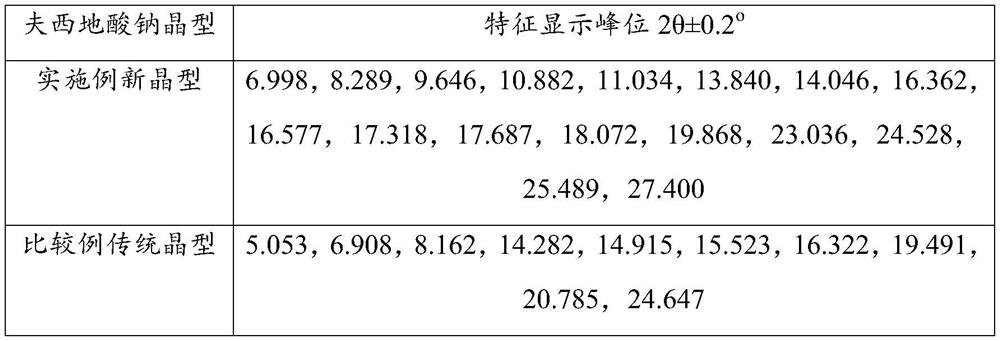

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method for the new crystal form of sodium fusidate, comprising the following steps:

[0035] Fusidic acid is dissolved in an alcohol solvent at 25-40°C, and sodium methoxide is added to obtain a sodium fusidic acid solution;

[0036] Under the condition of 20-30°C, dichloromethane was added dropwise to the sodium fusidate solution, stirred for 0.5-4 hours, and the solid was collected by solid-liquid separation; the solid was dried to obtain sodium fusidate new crystal form.

[0037] As in different embodiments, fusidic acid can be dissolved in alcohol solvent at 25°C, 30°C, 35°C, 40°C and other conditions.

[0038] In a specific embodiment of the present invention, the ratio of the fusidic acid to the alcohol solvent is 1 g: (1-2) mL. This ratio means that the alcohol solvent is used in an amount of 1 to 2 mL per 1 g of fusidic acid solid. For example, when the amount of fusidic acid solid is 10g, the amount of alcoho...

Embodiment 1

[0057] This embodiment provides a preparation method for a new crystal form of sodium fusidate, comprising the following steps:

[0058] (1) Weigh 20g of fusidic acid solid and place it in a reaction vessel, add 20mL of anhydrous methanol, heat to 40°C to dissolve the fusidic acid solid, then add sodium methoxide solid under stirring to obtain fusidic acid Sodium solution 25mL;

[0059] The molar ratio of the added amount of the sodium methoxide solid to the fusidic acid solid is 1:1.

[0060] (2) Control the temperature at 20°C, under stirring, add dichloromethane dropwise to the sodium fusidate solution obtained in step (1), at a rate of 300mL / h (5mL / min), when dichloromethane When the dropwise addition amount is 600mL, stop the dropwise addition, and continue to stir for 0.5h, then filter with suction, place the filter cake at 40°C and dry for 36h to obtain 14.3g of sodium fusidate crystals, the calculated yield is 68.6% . Its purity was determined to be 98.83% by HPLC. ...

Embodiment 2

[0062] This embodiment provides a preparation method for a new crystal form of sodium fusidate, comprising the following steps:

[0063] (1) Weigh 20g of fusidic acid solid and place it in a reaction vessel, add 40mL of anhydrous methanol, heat to 40°C to dissolve the fusidic acid solid, then add sodium methoxide solid under stirring to obtain fusidic acid Sodium solution 45mL;

[0064] The molar ratio of the added amount of the sodium methoxide solid to the fusidic acid solid is 1:1.

[0065] (2) Control the temperature at 25°C and add 1200 mL of dichloromethane dropwise to the sodium fusidate solution obtained in step (1) under agitation at a rate of 300 mL / h (5 mL / min). Afterwards, stirring was continued for 1 h, and then suction filtered, and the filter cake was dried at 45° C. for 48 h to obtain 15.6 g of sodium fusidate crystals, with a calculated yield of 74.8%. Its purity was determined to be 99.66% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com