Polymer containing lactide and preparation method thereof, medical material and surgical article

A technology of lactide and polymer, which is applied in the field of materials and chemical industry, can solve the problems of strength reduction and achieve good flexural strength retention rate and tensile strength retention rate, formability and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]The present invention further proposes a method for preparing a lactide-containing polymer as described above, comprising at least one of the following three steps:

[0041] (1) During the polymerization of polylactic acid prepared by lactide polymerization, when the polymerization reaction is carried out to 0.5-72h, adjust the pressure condition of the polymerization reaction to negative pressure and maintain it for 0.5-72h;

[0042] (2) After the polymerization reaction of preparing polylactic acid by lactide polymerization is completed, the polymerization product is vacuum-dried for 10-20 hours at 120° C. under a pressure of 1-10 mmHg;

[0043] (3) Washing and drying the polymerization product of polylactic acid prepared by polymerization of lactide with a solvent.

[0044] Decompression during the lactide polymerization process is conducive to the positive polymerization reaction, so that each lactide is connected to each other by ring opening. The preferred conditio...

Embodiment 1

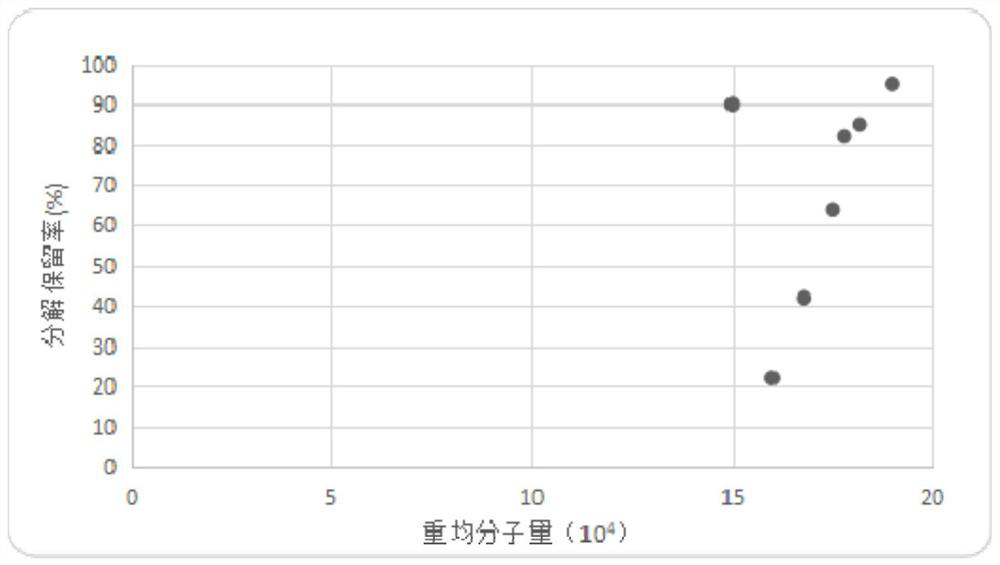

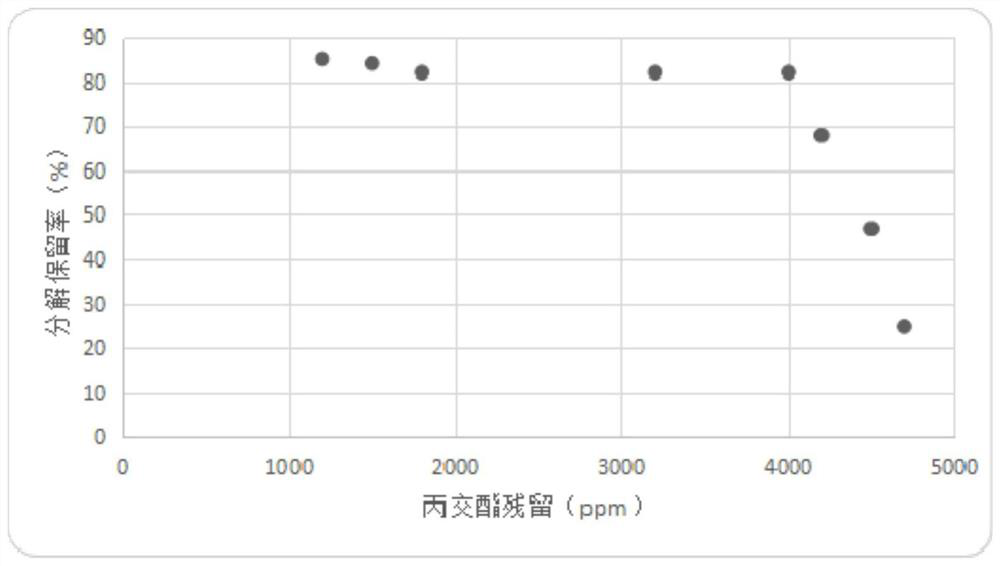

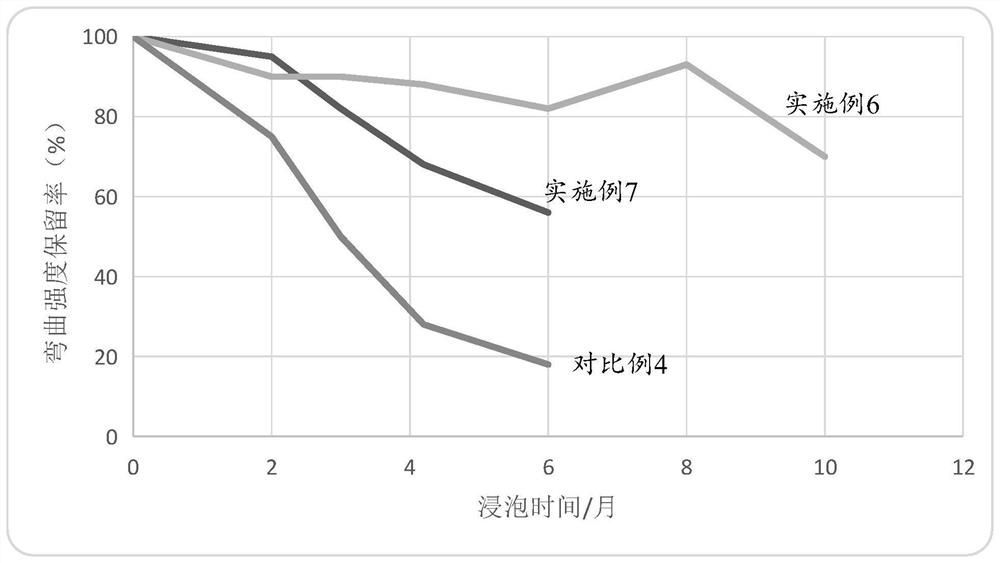

[0057] Under the condition that the molding temperature is 200-210°C, the polylactic acid is directly molded through the extruder without granulation, so that the diameter is Columns in the form of cylinders. The columnar material was subjected to vacuum thermal drying (under a reduced pressure of 1 mmHg, at 120° C. for 10 h) to obtain a columnar material with reduced lactide content. In addition, each pillar was stretched at a stretch ratio of 2.5 at a die temperature of 120-140°C using a hydrostatic extruder to prepare rods, each rod was cut and drawn to prepare a top diameter of A screw sample with a total length of 30 mm, the weight average molecular weight of the lactide-containing polymer in the screw sample is 189000, and the lactide content is 1319 ppm.

Embodiment 2

[0059] Under the condition that the molding temperature is 200~210℃, polylactic acid is directly molded through the extruder without granulation, so as to obtain a polylactic acid with a diameter of Columns in the form of cylinders. The column was subjected to vacuum thermal drying (under a reduced pressure of 10 mmHg, at 120° C. for 20 h) to obtain a column with reduced lactide content. In addition, each pillar was stretched at a stretch ratio of 2.5 at a die temperature of 120 to 140°C using a hydrostatic extruder to prepare rods, each rod was cut and drawn to prepare a top diameter of A screw sample with a total length of 30 mm, the weight average molecular weight of the lactide-containing polymer in the screw sample is 176,000, and the lactide content is 1442 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com