Method used for preparing high color fastness differential polyester staple fiber via dying of stock solution

A technology of polyester staple fiber and high color fastness, which is applied in the direction of adding pigments and single-component polyester artificial filaments to the spinning solution, which can solve the problems of continuous production of multi-color series and multi-color Pigments are uniformly dispersed, polyester compatibility problems, single species and other problems, to achieve the effects of high production efficiency, increased strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

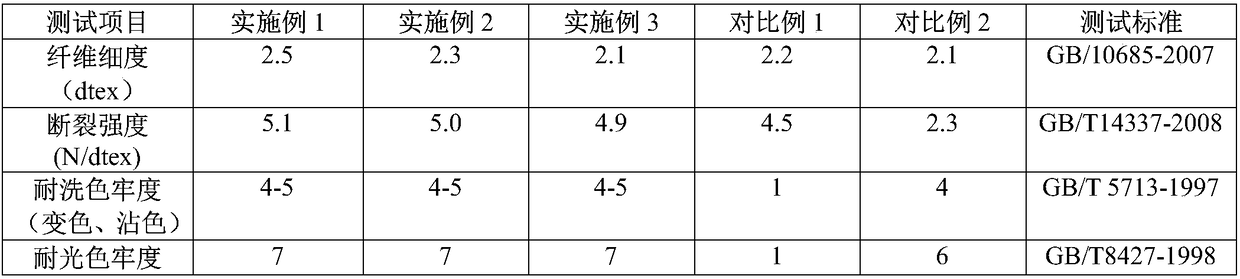

Embodiment 1

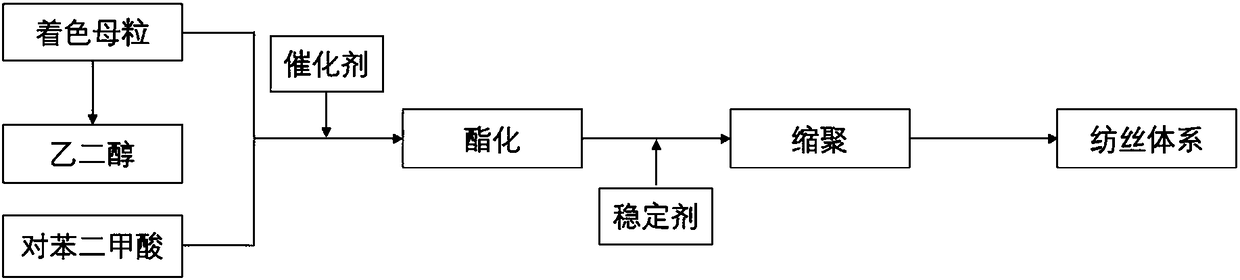

[0030] A method for preparing high color fastness differential polyester staple fiber by coloring with stock solution, the method may further comprise the steps:

[0031] (1) Preparation of masterbatch: (a) get cetyltrimethylammonium bromide and disperse it in 25% ethanol aqueous solution with a mass fraction of 1%, then add ammonia water therein to adjust the pH value 10, stirred at 25°C for 2 h under the condition of magnetic stirring; (b) Weighed tetraethyl orthosilicate and quinophthalone pigments with a mass ratio of 1:1 and added them to the reaction solution in step (a), the mass The fraction is 1%, reacted for 8h; (c) put the reaction solution of step (b) in a sand mill, then add 1% of the total mass of the solution silane coupling agent KH550 to grind for 3h, and then pass through a microporous membrane After filtering, washing, and drying in a blast drying oven at 85°C, the desired coloring masterbatch with a particle size of 50nm is obtained;

[0032] (2) Add 1% co...

Embodiment 2

[0040](1) Preparation of masterbatch: (a) get cetyltrimethylammonium bromide and disperse it in 30% ethanol aqueous solution with a mass fraction of 2%, then add ammonia water therein to adjust the pH value 11, stirred at 25°C for 1.5 h under the condition of magnetic stirring; (b) Weighed tetraethyl orthosilicate and fused ring ketone pigments with a mass ratio of 1:1 and added them to the reaction solution in step (a), The mass fraction is 2%, and the reaction is 5-8h; (c) the reaction solution of step (b) is placed in a sand mill, and then 3% of the total mass of the solution is added to the silane coupling agent KH550 to grind for 4h, and then through micro After filtering with a pore filter membrane, wash, and dry in an 88°C blast drying oven to obtain the required coloring masterbatch with a particle size of 300nm;

[0041] (2) Add 3% coloring masterbatch and 40% ethylene glycol into the reaction kettle, and stir for 1-2 hours at a temperature of 50-60°C;

[0042] (3) A...

Embodiment 3

[0049] (1) Preparation of color masterbatch: (a) get cetyltrimethylammonium bromide and disperse it in 35% ethanol aqueous solution with a mass fraction of 3%, then add ammonia water to it to adjust the pH value Stir at 25°C for 1 h under the condition of magnetic stirring; (b) Weigh tetraethyl orthosilicate and phthalocyanine pigments with a mass ratio of 1:1 and add them to the reaction solution in step (a), the mass fraction 3%, react for 5h; (c) put the reaction solution in step (b) in a sand mill, add 5% silane coupling agent KH550 of the total mass of the solution to grind for 3h, and then filter through a microporous membrane Finally, wash and dry in a blast drying oven at 90°C to obtain the desired coloring masterbatch with a particle size of 500nm;

[0050] (2) Add 6% coloring masterbatch and 45% ethylene glycol into the reaction kettle, and stir for 1 hour at a temperature of 60°C;

[0051] (3) Add 55% terephthalic acid and 0.5% antimony triacetate to the reaction k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com