Composition, fireproof coating containing composition and preparation method of fireproof coating

A fire-resistant coating and composition technology, applied in the field of flame-retardant materials, can solve the problems of small number of parts, large amount of use, and inability to form hard ceramic bodies, etc., and achieve the effect of increasing the fire-resistant limit, improving the fire-resistant limit, and facilitating popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

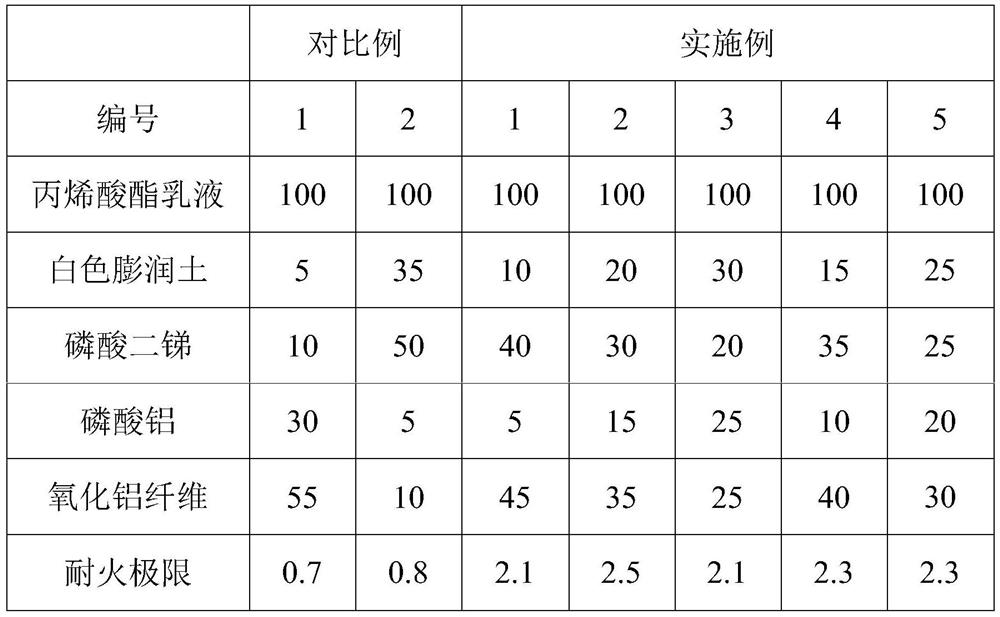

Embodiment 1

[0026] According to the following mass ratio weighing each prepared component: 10 copies of white bentonite, 40 copies of phosphate, 5 copies of aluminum phosphate, 45 aluminum oxide fibers; 45 parts of alumina, pour each component into the vertical high-speed mixer, add acrylic acid The fireproof coating 1 is obtained in the ester emulsion 100.

[0027] The fire-resistant lifting limit of the fireproof coating 1 was measured at 2.1 h.

Embodiment 2

[0029] According to the following mass ratio weighing each prepared component: 20 copies of white bentonite, 30 pieces of phosphate, 15 pieces of aluminum phosphate, 35 aluminum oxide fibers; 1 component is poured into the vertical high-speed mixer and added acrylic acid after mixing The ester emulsion is stirred for 15 min to obtain a fireproof coating 2.

[0030] The fire-resistant lifting limit of the fire painting 2 was 2.5 h.

Embodiment 3

[0032] According to the following mass ratio weighing each prepared component: 30 copies of white bentonite, 20 copies of phosphate, 25 pieces of aluminum phosphate, 25 aluminum oxide fibers; 1 pour each component into the vertical high-speed mixer After mixing acrylic acid The ester emulsion is stirred for 15 min to obtain a fireproof coating 3.

[0033] The fire-resistant lifting limit of the fireproof coating 3 was 2.1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com