Synthesis method of POSS-based reversible thermochromic membrane material

A technology of thermochromic and synthetic method, applied in the field of synthesis of POSS-based reversible thermochromic film materials, can solve the problem of less color-changing materials, and achieve the effects of fast discoloration speed, simple post-processing method and mild processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

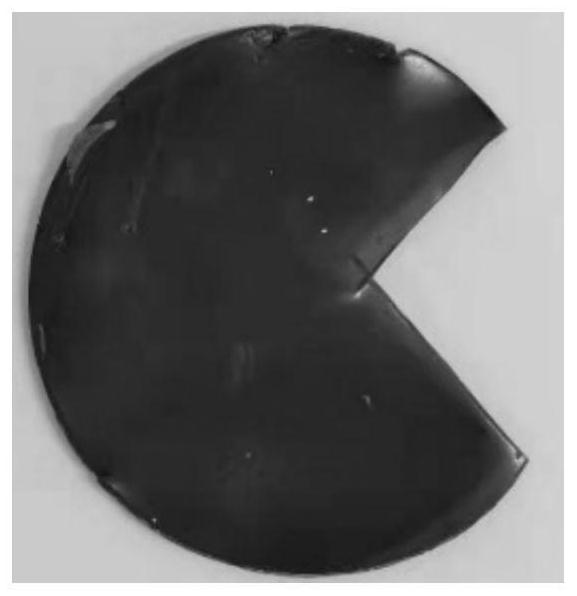

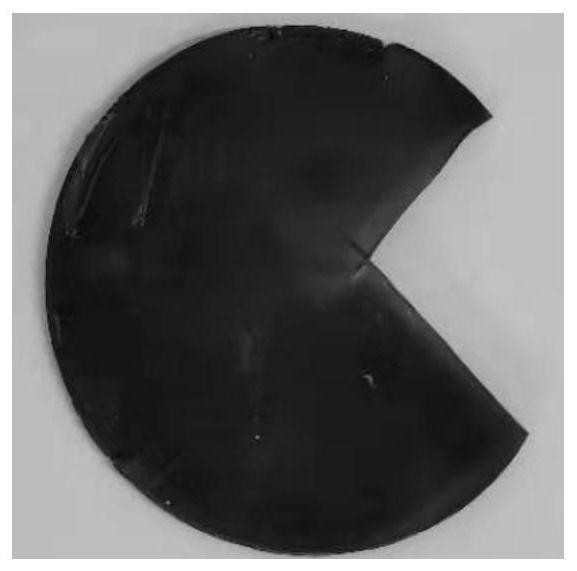

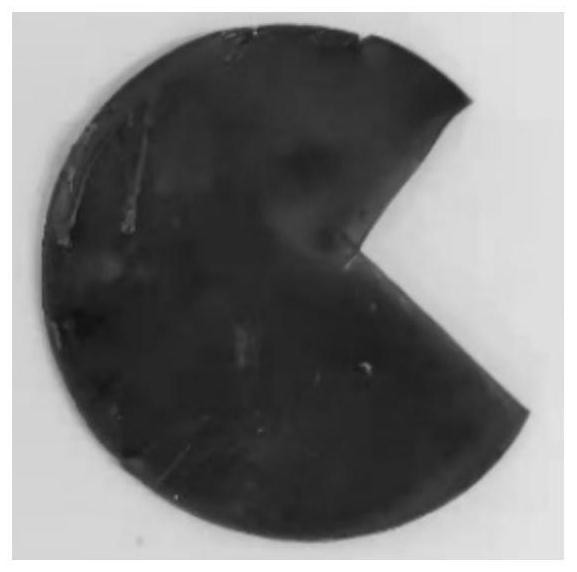

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: what this embodiment records is a kind of synthetic method of POSS-based reversible thermochromic film material, and described method comprises the following steps:

[0023] Step 1, dissolving POSS in water;

[0024] Step 2, chromium salt is added in the POSS aqueous solution;

[0025] Step 3: Stir at 20-40°C for 1-24 hours, volatilize the solvent at 20-80°C, and obtain the POSS-based reversible thermochromic film material after the solvent is completely volatilized.

specific Embodiment approach 2

[0026] Specific embodiment two: the synthetic method of a kind of POSS-based reversible thermochromic film material described in specific embodiment one, in step one, described POSS is polyaminopropyl POSS or polyaminophenyl POSS, the number of functional groups of POSS 2-8 pieces. The amino group coordinates with the metal, and the number of 2-8 can form a cross-linked structure.

specific Embodiment approach 3

[0027] Specific embodiment three: the synthesis method of a POSS base film material with both reversible discoloration and ultraviolet shielding described in specific embodiment one, in step one, the mass ratio of POSS to water is 0.1-1:1 .

[0028] Embodiment 4: A method for synthesizing a POSS base film material with reversible discoloration and UV shielding described in Embodiment 1. In step 2, the mass ratio of the chromium salt to POSS is 1 to 4: 1~5.

[0029] Specific embodiment five: the synthetic method of a kind of POSS base film material that has both reversible discoloration and ultraviolet shielding described in specific embodiment one, in step 2, described chromium salt is chromium nitrate nonahydrate or chlorinated hexahydrate chromium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com