5G radome composite material and manufacturing method thereof

A composite material and manufacturing method technology, applied in the field of radome, can solve the problems of reducing the density and dielectric constant of 5G radome composite materials, and achieve the effects of reducing density and dielectric constant, simple manufacturing method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A 5G antenna composite composite, the composite raw material comprising the following components by weight: polypropylene, 15 glass fibers, 15 parts of the kaolin and auxiliary agent.

[0029] Among them, the kaolin is a kaolin that is calcined by a special process.

[0030] Further, the auxiliary agent includes a lubricant and an ultraviolet.

[0031] Further, the aid also includes an antioxidant and a flame retardant.

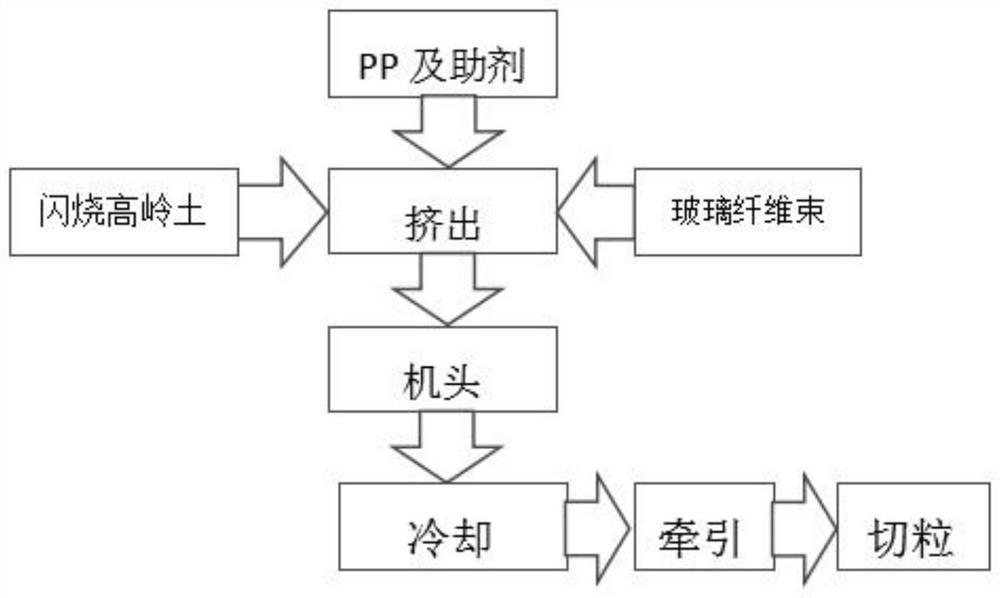

[0032] A method of fabricating a 5G antenna cover composite material comprising the steps of:

[0033] S101: First, add polypropylene and auxiliaries to the feet of the exhaust double screw extruder, and the flashed kaolin is added to another feet;

[0034] S102: The fiberglass is then added to the filament port of the exhaust twin screw extruder, wherein the glass fibers are a joint yarn;

[0035] S103: Further, the glass fibers are broken by the left-handed screw and kneading device, and the polypropylene, auxiliaries, flashed kaolin and glass fibers are...

Embodiment 2

[0038] A 5G antenna composite composite material comprising 70 polypropylene, 20 parts of glass fiber, 20 parts of glass fiber, and aid for 5 copper.

[0039] Further, the auxiliary agent includes a lubricant and an ultraviolet.

[0040] Further, the aid also includes an antioxidant and a flame retardant.

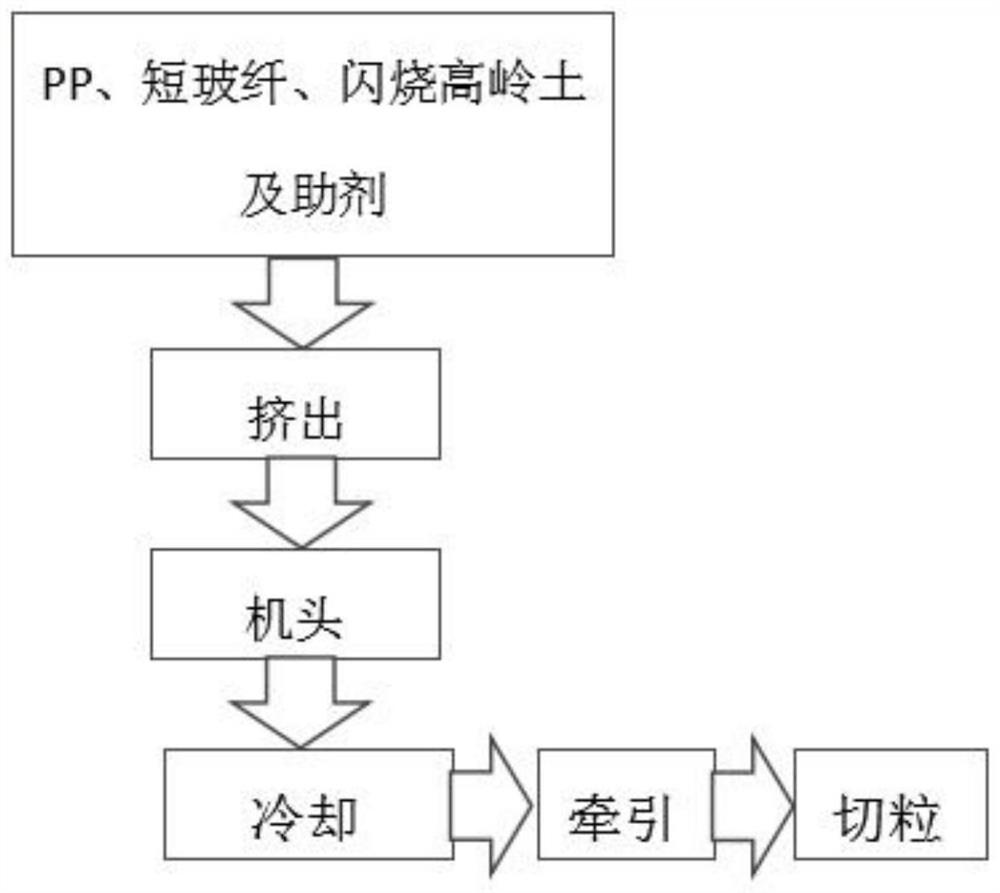

[0041] A method of fabricating a 5G antenna cover composite material comprising the steps of:

[0042] S201: First, add polypropylene and auxiliaries to the exhaust double screw extruder feed funnel, and add the short-cut glass fiber and the flash of kaolin to another feeding funnel;

[0043] S202: Then, the polypropylene, auxiliaries, flashed kaolin and glass fibers are fed together into the cartridge by the feed screw, and mix well in the cartridges, auxiliary kaolin and glass fibers;

[0044] S203: Finally, the volatile substance in the mixing is removed by the exhaust segment, further plastic, extruded, passed through the motor head extruded strip, then cooled, dried, tract...

Embodiment 3

[0046] A 5G antenna composite composite, the composite raw material comprising the following components by weight: polypropylene, 15 glass fibers, 15 parts of the kaolin and auxiliary agent.

[0047] Further, the auxiliary agent includes a lubricant and an ultraviolet.

[0048] Further, the aid also includes an antioxidant and a flame retardant.

[0049] A method of fabricating a 5G antenna cover composite material comprising the steps of:

[0050] S101: First, add polypropylene and auxiliaries to the feet of the exhaust double screw extruder, and the flashed kaolin is added to another feet;

[0051] S102: The fiberglass is then added to the filament port of the exhaust twin screw extruder, wherein the glass fibers are a joint yarn;

[0052] S103: Further, the glass fibers are broken by the left-handed screw and kneading device, and the polypropylene, auxiliaries, flashed kaolin and glass fibers are fed into the cartridge by the feed screw, and the polypropylene, auxiliaries, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com