Method for maintaining polishing efficiency of magnetorheological polishing liquid, stabilizer and preparation method of stabilizer

A magnetorheological polishing and stabilizer technology, applied in the field of magnetorheological polishing, can solve the problems of inability to meet the requirements of long-term use, poor stability of polishing efficiency, etc., so as to make up for the decline of polishing efficiency, meet the requirements of long-term use, and achieve good polishing The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

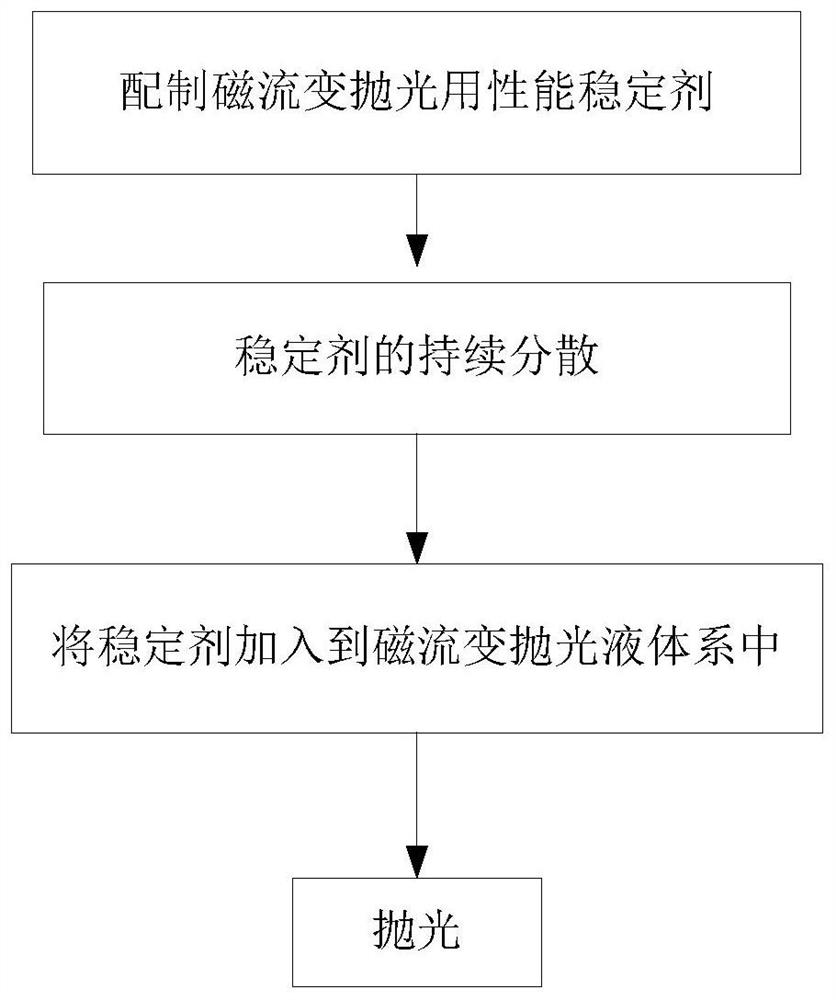

[0047] Preparation of performance stabilizer for magnetorheological polishing

[0048] Step 1: Add 10.0g of dispersant polyvinyl alcohol into 500ml of deionized water, and stir until the dispersant is completely dissolved;

[0049] Step 2: Continue to add 15.0g of wetting agent propylene glycol, and stir until evenly mixed;

[0050] Step 3: continue to add 8.0g of antioxidant sodium carbonate, stir well to form base carrier liquid;

[0051] Step 4: Weigh 75.0 g of cerium oxide abrasive grains, slowly add them into the stirring base carrier liquid, and keep stirring for 10 minutes to obtain a performance stabilizer for magnetorheological polishing.

Embodiment 2

[0053] Step 1: Add 5.5g of dispersant polyacrylamide into 500ml of deionized water, and stir until the dispersant is completely dissolved;

[0054] Step 2: Continue to add 15.0g of wetting agent propylene glycol, and stir until evenly mixed;

[0055] Step 3: continue to add 8.0g of antioxidant sodium carbonate, stir well to form base carrier liquid;

[0056] Step 4: Weigh 75.0 g of cerium oxide abrasive grains, slowly add them into the stirring base carrier liquid, and keep stirring for 10 minutes to obtain a performance stabilizer for magnetorheological polishing.

[0057]The difference between this example and Example 1 is that polyvinyl alcohol is used as a dispersant to prepare the cerium oxide stabilizer.

Embodiment 3

[0059] Step 1: Add 10.0g of dispersant polyvinyl alcohol into 500ml of deionized water, and stir until the dispersant is completely dissolved;

[0060] Step 2: Continue to add 15.0g of wetting agent propylene glycol, and stir until evenly mixed;

[0061] Step 3: continue to add 8.0g of antioxidant sodium carbonate, stir well to form base carrier liquid;

[0062] Step 4: Weigh 50.0 g of cerium oxide abrasive grains, slowly add them into the stirring base carrier liquid, and keep stirring for 10 minutes to obtain a performance stabilizer for magnetorheological polishing.

[0063] The difference between this embodiment and Embodiment 1 is that the content of cerium oxide abrasive particles is reduced.

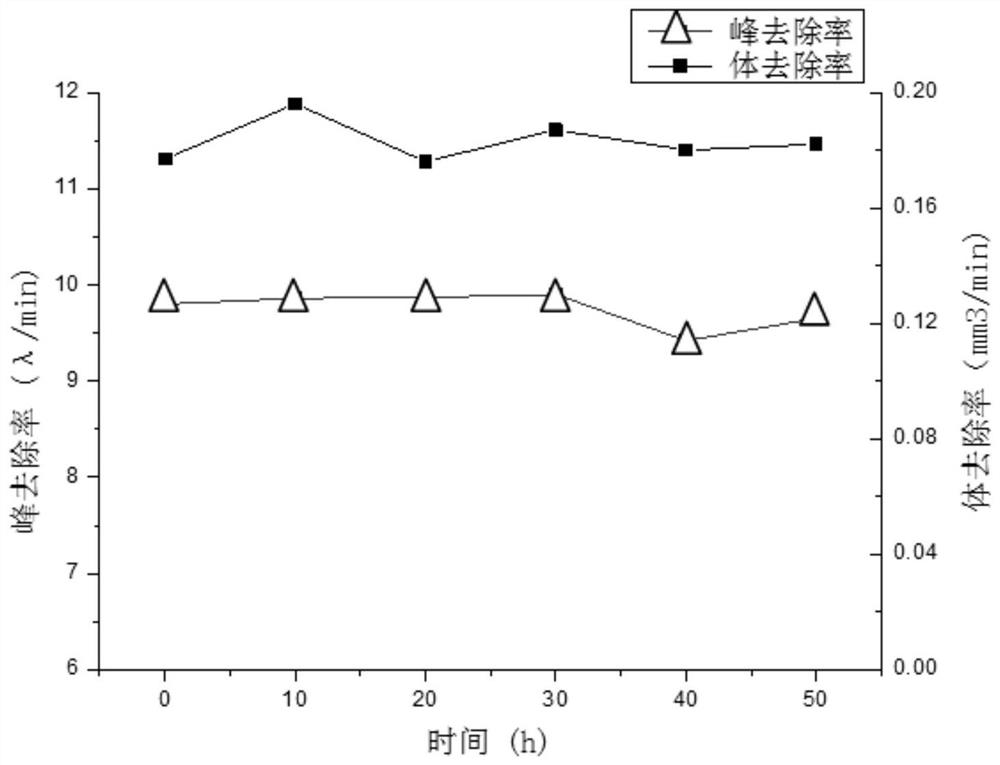

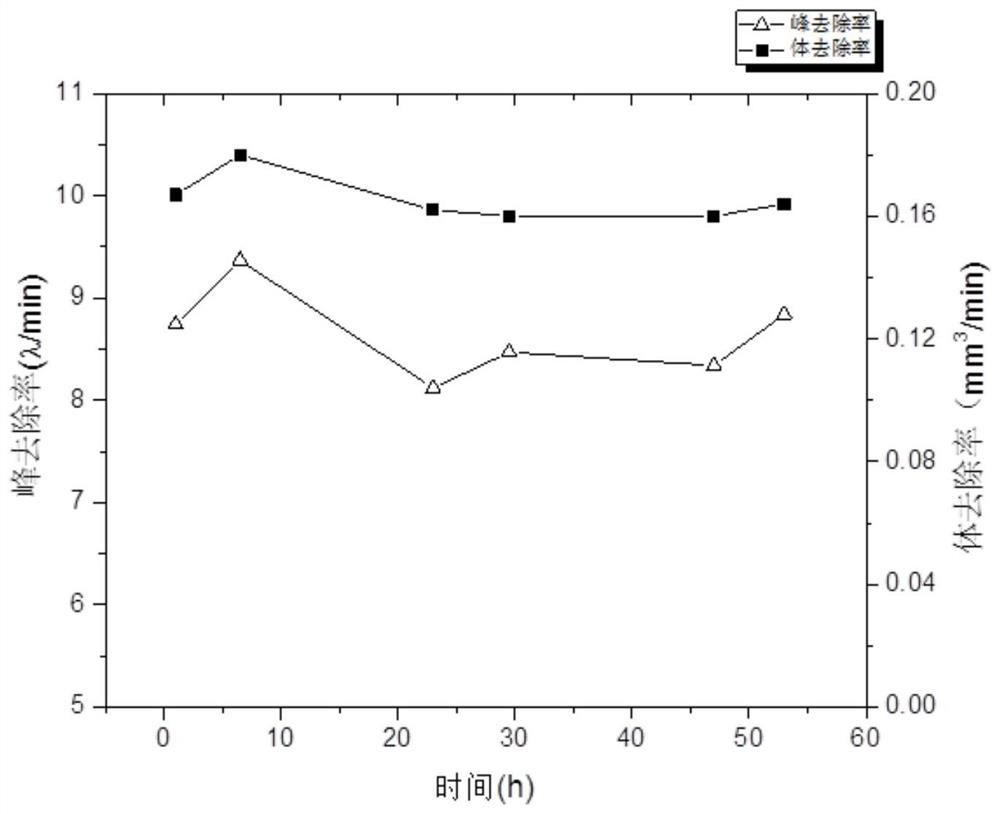

[0064] 2. Effect of performance stabilizer for magnetorheological polishing on the efficiency of magnetorheological polishing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com