Heavy oil hydrogenation method and system

A heavy oil hydrogenation and heavy oil technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve problems such as poor system stability, increased equipment investment, and potential safety hazards, so as to reduce potential safety hazards, save energy consumption, The effect of increasing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

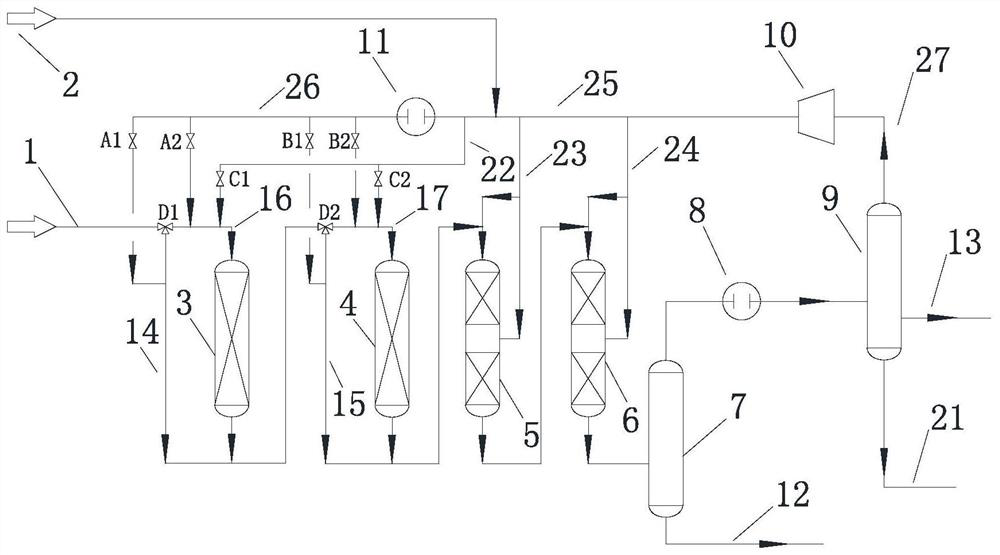

[0073] The heavy oil hydrogenation system of this embodiment is as figure 1 As shown, the system includes a heavy oil inlet 1, a first hydrogenation protection reactor 3, a second hydrogenation protection reactor 4, a first hydrogenation reactor 5, a second hydrogenation reactor 6, a hot high-pressure separator 7, Hot high fraction gas heat exchanger 8 , cold high fraction separator 9 and circulating hydrogen compressor 10 .

[0074] A first inlet pipeline 16 is connected between the heavy oil inlet 1 and the inlet of the first hydrogenation protection reactor 3, and the reaction oil gas outlet of the first hydrogenation protection reactor 3 is connected with the inlet of the second hydrogenation protection reactor 4. There is a second inlet pipeline 17; the outlet of the second hydrogenation protection reactor 4 communicates with the inlet of the first hydrogenation reactor 5 through the second outlet pipeline. A first jumper 14 is also provided between the heavy oil inlet 1...

Embodiment 2

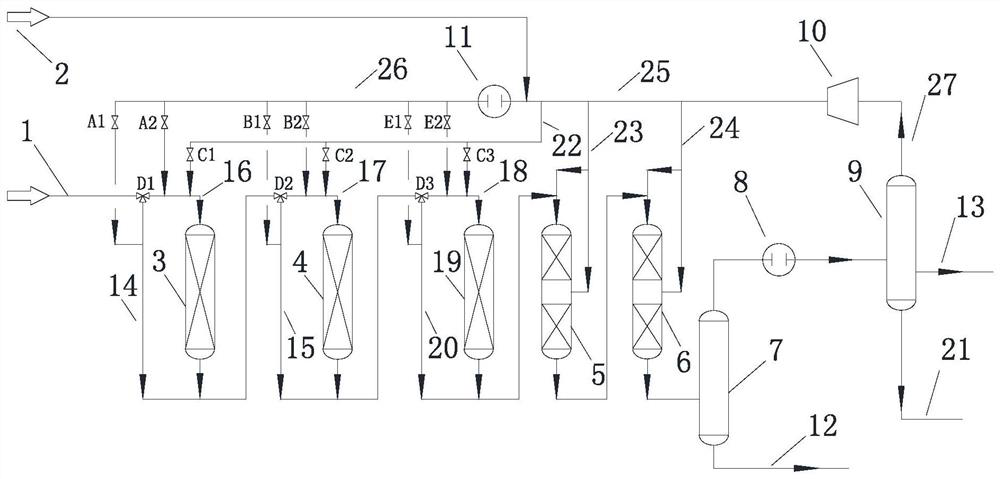

[0089] The heavy oil hydrogenation system of this embodiment is as figure 2As shown, the system includes a heavy oil inlet 1, a first hydrogenation protection reactor 3, a second hydrogenation protection reactor 4, a third hydrogenation protection reactor 19, a first hydrogenation reactor 5, a second hydrogenation reaction device 6, hot high pressure separator 7, hot high fraction gas heat exchanger 8, cold high fraction separator 9 and circulating hydrogen compressor 10.

[0090] Such as figure 2 As shown, the heavy oil hydrogenation system of the heavy oil hydrogenation system of this embodiment is basically the same as that of Embodiment 1, the difference is that the system of this embodiment adds a third hydrogenation protection reactor 19, and the third hydrogenation protection reaction The inlet of device 19 communicates with the outlet of the second hydrogenation protection reactor 4 through the third inlet pipeline 18, and a third span is arranged between the outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap