Efficient heat-preservation wood-plastic wallboard

A wood-plastic wallboard and wood-plastic technology, which is used in thermal insulation, walls, building components, etc., can solve the problems of poor thermal insulation performance, insufficient size, and large raw material width requirements, achieve high-efficiency thermal insulation performance, improve pressure-bearing performance, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

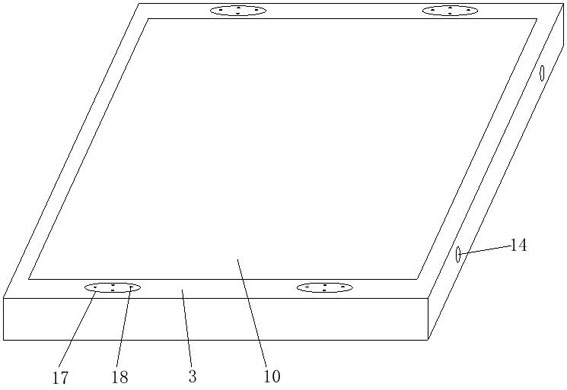

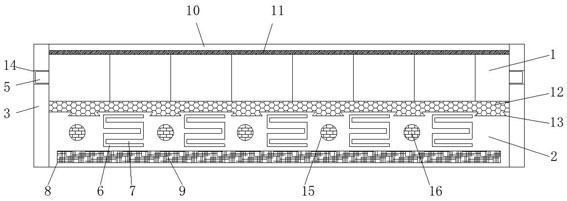

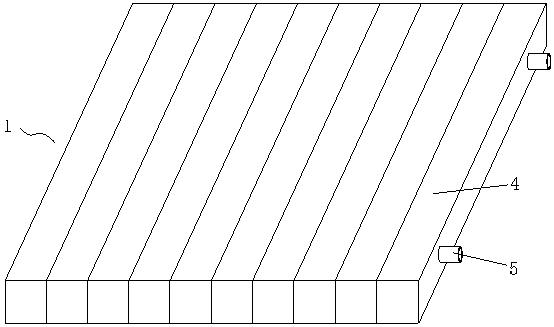

[0020] according to figure 1 , 2 , 3, the present embodiment proposes a high-efficiency thermal insulation wood-plastic wallboard, including a temperature-insulating wood-plastic layer 1, a heating wood-plastic layer 2 and a wood-plastic frame 3, and the top of the temperature-insulating wood-plastic layer 1 is installed There is a heating wood-plastic layer 2, and the sides of the temperature-insulating wood-plastic layer 1 and the heating wood-plastic layer 2 are surrounded by a wood-plastic frame 3, and the heating wood-plastic layer 2 includes a wood-plastic strip 4 and a mounting pipe 5. The wood-plastic strip 4 is provided with multiple groups, the interior of the wood-plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com