Magnetic drive pump with high stability

A magnetic pump and stability technology, which is applied to parts, pumps, pump devices, etc. of pumping devices for elastic fluids, can solve problems such as poor stability performance and component damage, and achieve reduced jitter amplitude and smooth performance High, limited effect Ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

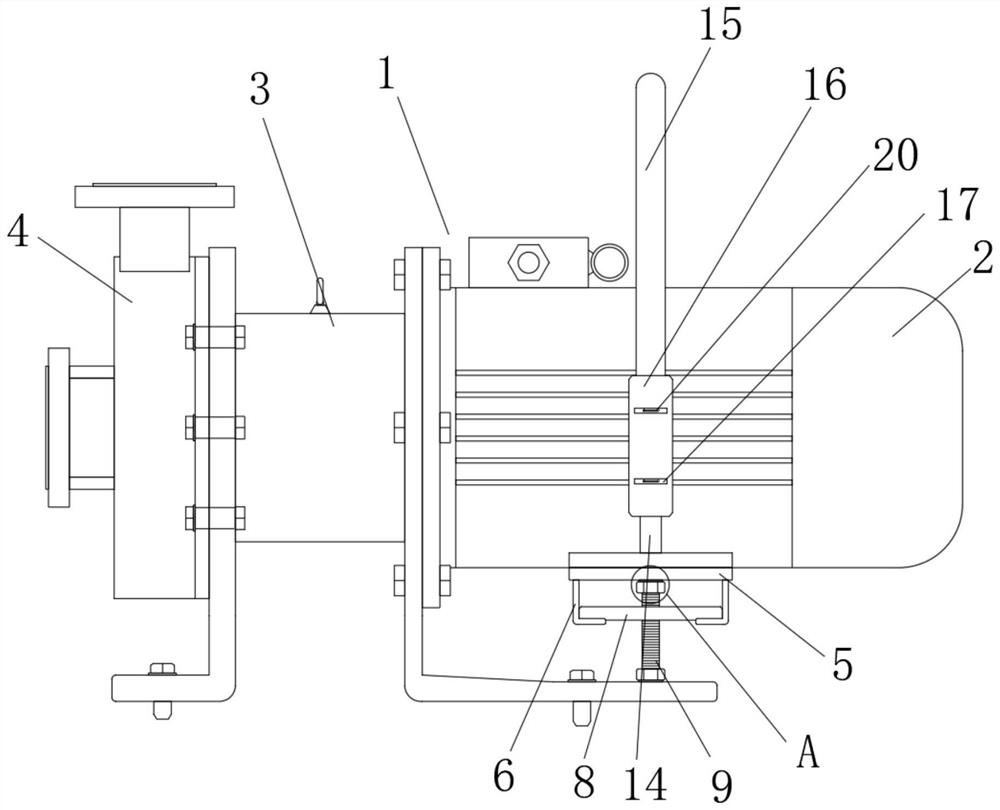

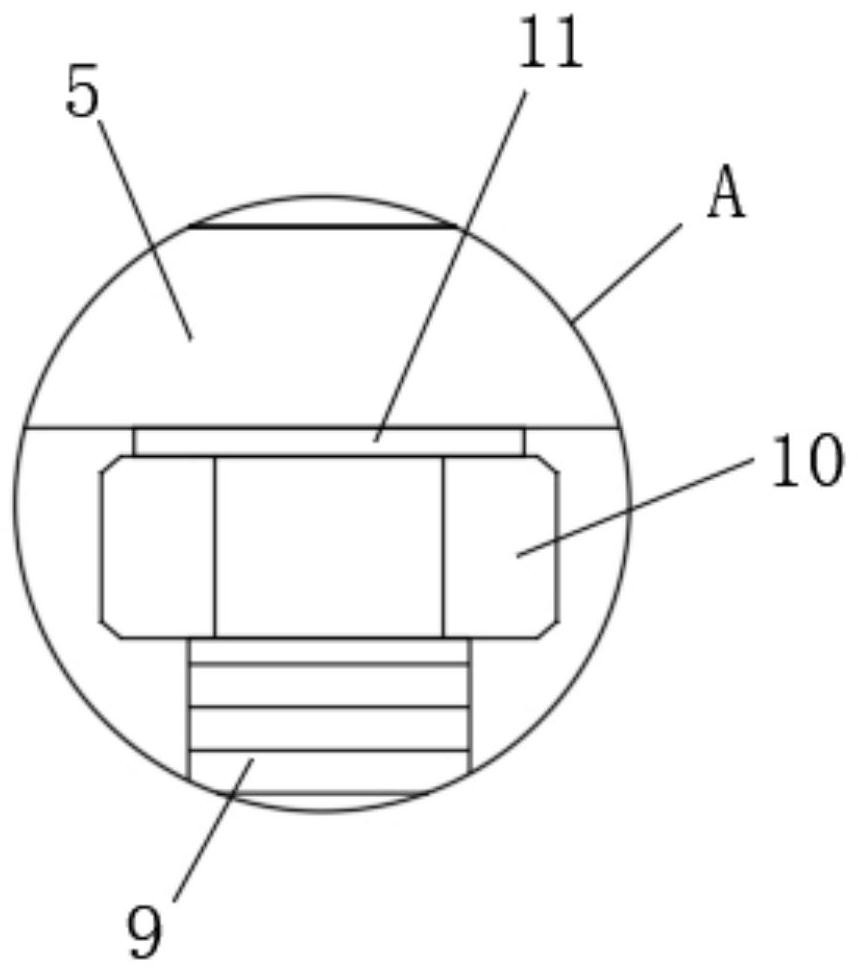

[0036] see Figure 1-3, the magnetic pump with high stability of the present invention includes a magnetic pump main body 1, the magnetic pump main body 1 includes a motor 2, a bracket 3 and a pump casing 4; the bracket 3 includes a support plate, and the inner bottom of the support plate is provided with a slot 12. The bottom of the motor 2 is fixedly welded with the first fixed plate 5, and the left and right sides of the bottom of the first fixed plate 5 are integrally formed with an "L"-shaped receiving plate 6, and the inner bottom of the receiving plate 6 is provided with a concave groove 7 and A connecting plate 8 matching the horizontal and vertical diameters is movably clamped between the insides of the two recessed grooves 7, and the center of the top and bottom of the connecting plate 8 is fixedly connected with a threaded rod 9, and the surfaces of the two threaded rods 9 are threaded. Connected with nuts 10, the sides of the two nuts 10 that are far away from each...

Embodiment 2

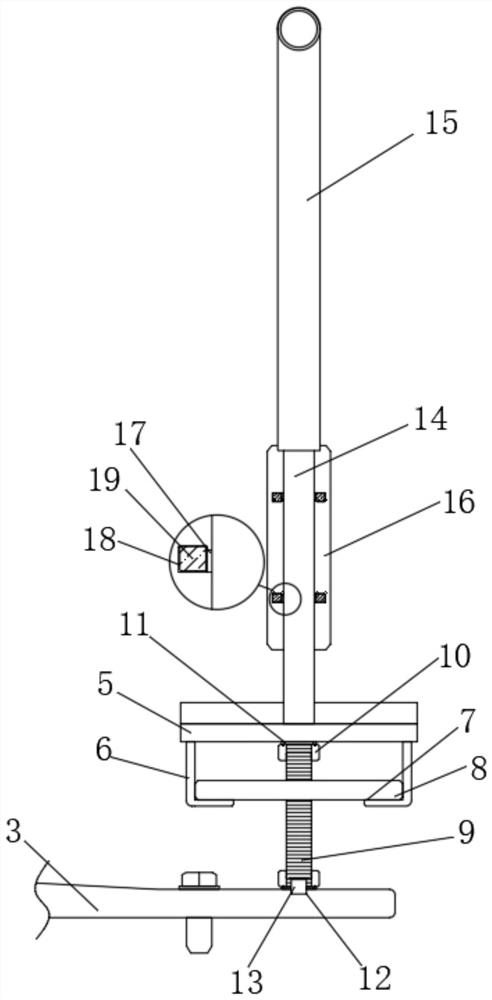

[0038] see Figure 4-5 , the front and the back of the first fixing plate 5 respectively protrude to the front and the back of the bottom of the motor 2, the top of the first fixing plate 5 and the positions close to the front and the back of the motor 2 respectively are fixedly connected with protruding rods 14 along the vertical direction, The outer side of the protruding rod 14 is provided with a grab bar 15 which is convenient for grabbing and transporting the magnetic pump. Before the magnetic pump is installed and during the handling operation, the staff can use one hand to grab the grab bar 15 to lift and apply pressure upwards. , and use the other hand to drag a certain point at the bottom of the pump casing 4, and then lift, carry, and move the magnetic pump.

Embodiment 3

[0040] see Figure 6-7 , the front and bottom of the back of the grab bar 15 are fixedly connected with a second fixed plate 16, and the fronts of the two second fixed plates 16 are provided with openings and plugged with a plug-in board 17, and the plug-in board 17 is close to the two second fixed boards. Two third fixing plates 18 are integrally formed on the opposite side of the two fixing plates 16, and the vertical diameter between the top surface and the bottom of a plurality of third fixing plates 18 is the same as the vertical diameter between the two nuts 10 opposite surfaces. The diameters are equal, and a cavity with a diameter larger than the nut 10 is left between the two third fixing plates 18 close to the plurality of plug-in boards 17 respectively. The side of the third fixing plate 18 away from the plug-in board 17 is fixedly connected with a magnet block 19. The third fixed plate 18 includes a horizontal plate and a vertical plate. The bottom ends of the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com