Cross shaft closed forging process

A closed-shaft and cross-shaft technology, applied in the field of cross-shaft closed forging technology, can solve the problems of wrong forgings, high scrap rate of forgings, increase in manufacturing costs, etc., achieve thickness control, solve the phenomenon of wrong molds, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

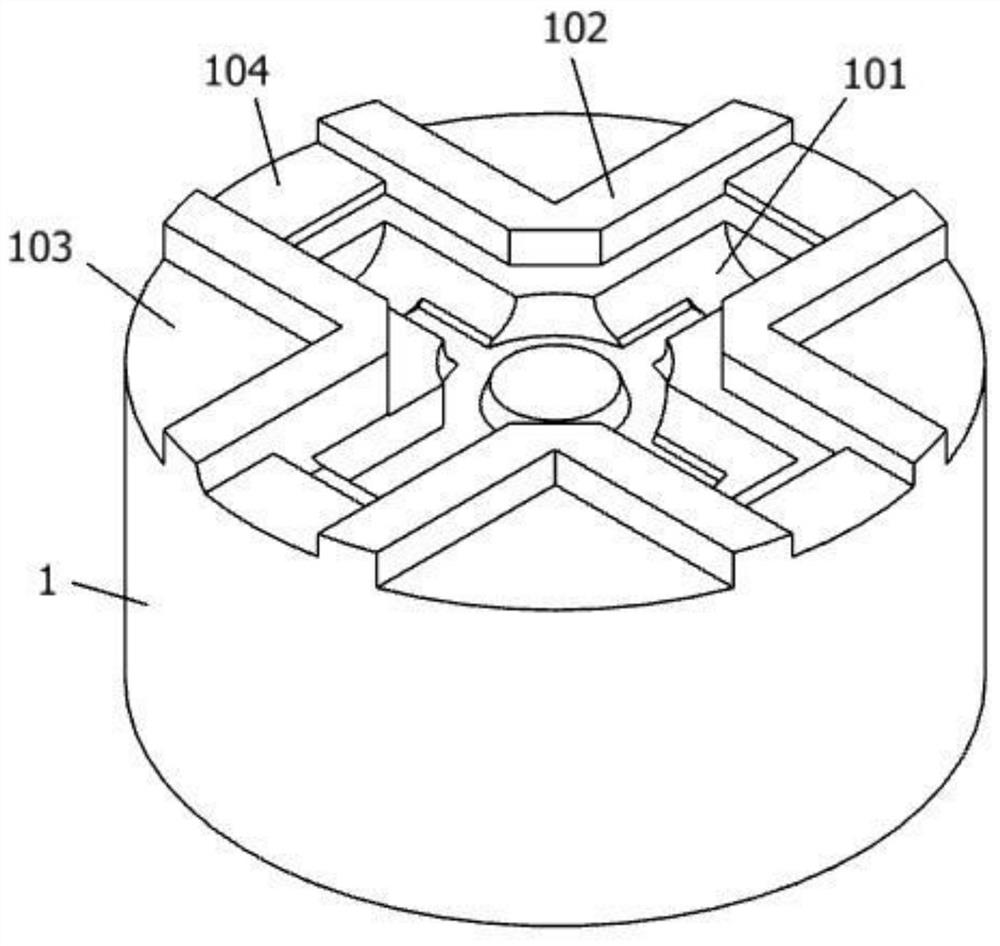

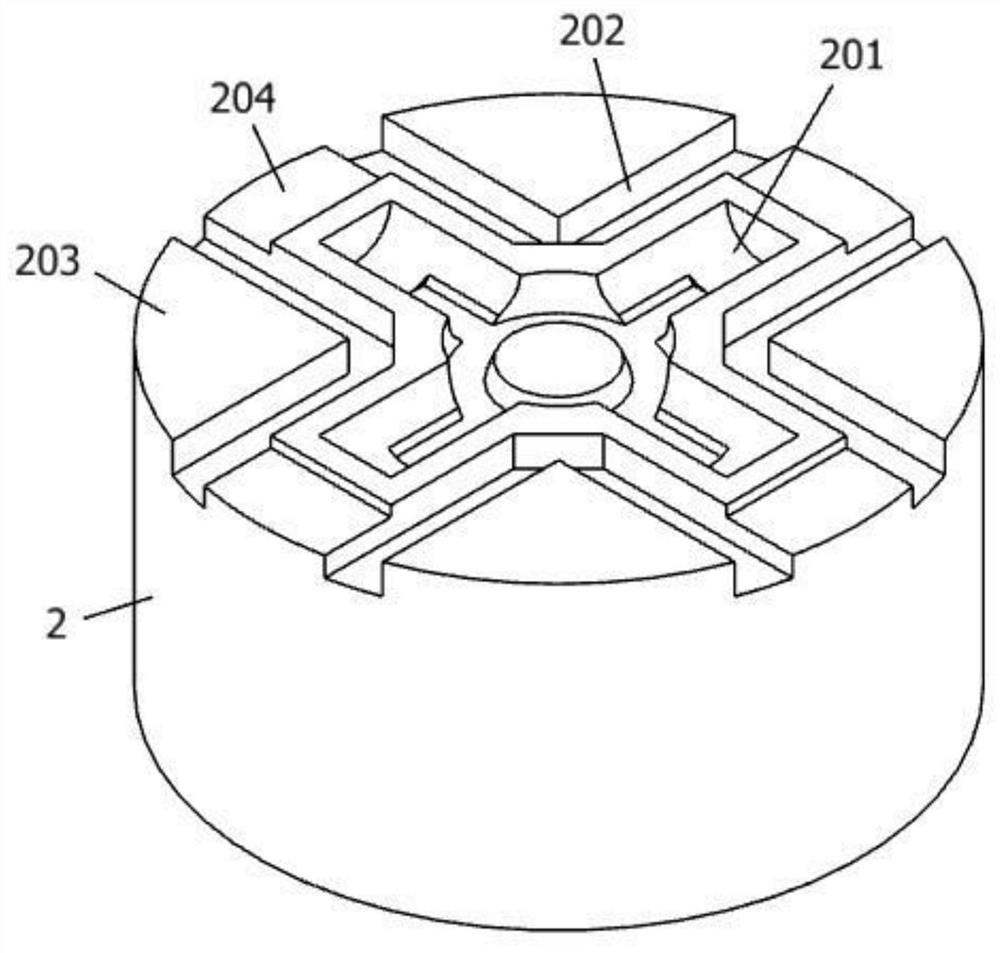

[0029] as attached Figure 1-2 shown:

[0030] The cross-axis closed forging process includes: an upper die 1, a cross-axis upper model groove 101 is provided at the axial center of the bottom end face of the upper die 1; a total of four resistance tables 104 are arranged on the bottom end face of the upper die 1 in a circular array shape, and the four The resistance tables 104 correspond to the four extending ends of the model groove 101 on the cross axis respectively; the bottom end surface of the upper mold 1 is provided with four locks 102 in a ring-shaped array, and the four locks 102 and the four resistance tables 104 are arranged in the same shape. Distributed at intervals; a lower mold 2 matched with the upper mold 1 is arranged directly under it; a cross-axis lower mold groove 201 is provided at the axial center of the top surface of the lower mold 2; the top surface of the lower mold 2 is provided with four resistance tables in a ring-shaped array. The card slots 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com