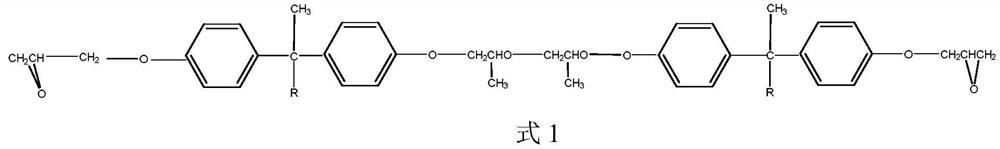

Modified epoxy resin, preparation method of modified epoxy resin, emulsion preparation method of modified epoxy resin and application thereof

A technology of bisphenol epoxy resin and waterproof material, which is used in epoxy resin coatings, polyether coatings, coatings, etc., can solve the expansion and contraction reaction and decline of cement molecules, the penetration of water molecules into cement, and the stress on coatings. Splitting, aging and other problems, to achieve the effect of strong expansion and shrinkage adaptability, good anti-aging effect, excellent water resistance and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

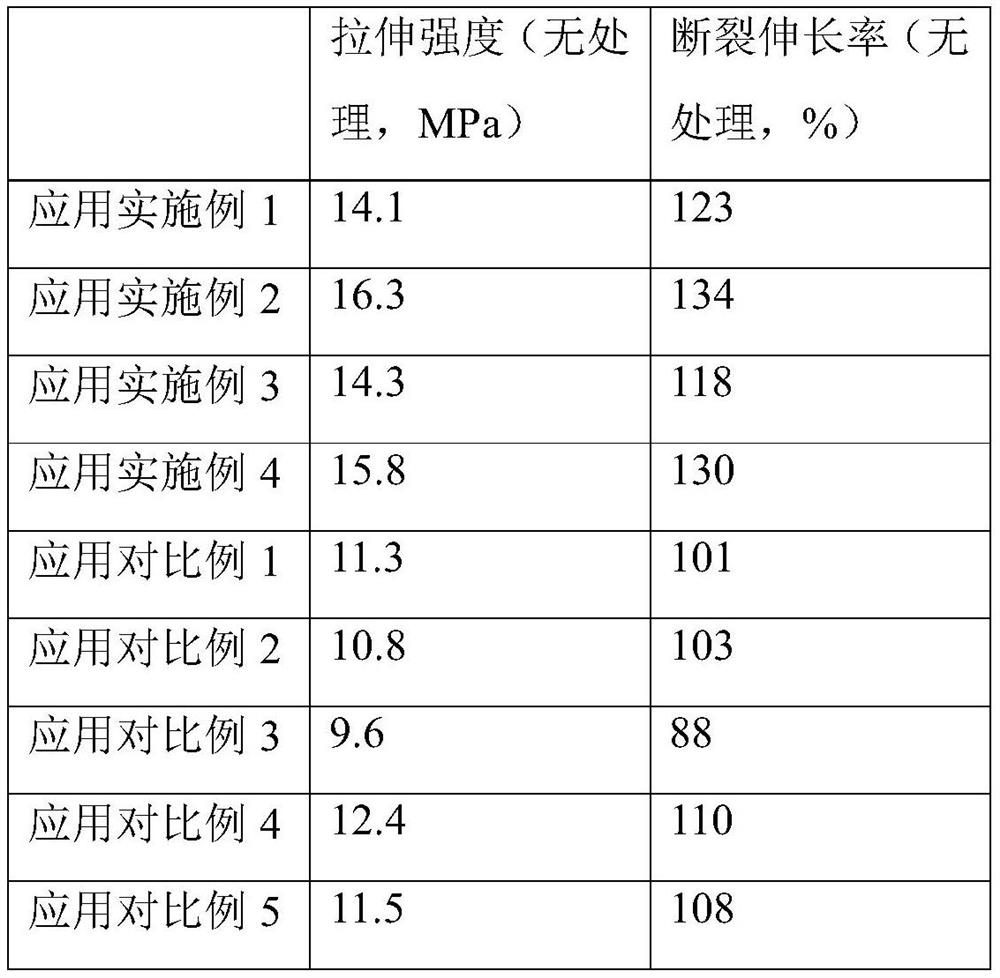

Examples

Embodiment 1

[0036] A kind of emulsion preparation method of modified bisphenol epoxy resin, its preparation step is as follows:

[0037] Step 1: Prepare 55 parts of modified bisphenol epoxy resin, 55 parts of polyethylene glycol, 1 part of TEA catalyst, 8 parts of water and 4 parts of emulsifier respectively according to parts by weight;

[0038] Step 2: Heat polyethylene glycol at 90°C to melt, add modified bisphenol epoxy resin and TEA catalyst, and stir evenly;

[0039] Step 3: Heat the evenly stirred mixture to 115° C., and maintain this temperature for 8 hours to obtain a water-based modified bisphenol epoxy resin;

[0040] Step 4: Add water and an emulsifier to the water-based modified bisphenol epoxy resin, stir and mix to prepare a modified bisphenol epoxy resin emulsion.

[0041]Wherein, the synthesis method of the modified bisphenol epoxy resin is as follows: according to the molar ratio, 1 part of bisphenol A is mixed with 0.05 part of bisphenolic acid, and then 2.14 parts of ...

Embodiment 2

[0043] A kind of emulsion preparation method of modified bisphenol epoxy resin, its preparation step is as follows:

[0044] Step 1: Prepare 70 parts of modified bisphenol epoxy resin, 30 parts of polyethylene glycol, 2 parts of TEA catalyst, 8 parts of water and 8 parts of emulsifier respectively according to parts by weight;

[0045] Step 2: Heat polyethylene glycol at 90°C to melt, add modified bisphenol epoxy resin and TEA catalyst, and stir evenly;

[0046] Step 3: Heat the evenly stirred mixture to 115° C., and maintain this temperature for 8 hours to obtain a water-based modified bisphenol epoxy resin;

[0047] Step 4: Add water and an emulsifier to the water-based modified bisphenol epoxy resin, stir and mix to prepare a modified bisphenol epoxy resin emulsion.

[0048] Wherein, the synthesis method of the modified bisphenol epoxy resin is as follows: according to the molar ratio, 1 part of bisphenol A is mixed with 0.13 part of bisphenolic acid, and then 2.3 parts of...

Embodiment 3

[0050] A kind of emulsion preparation method of modified bisphenol epoxy resin, its preparation step is as follows:

[0051] Step 1: Prepare 80 parts of modified bisphenol epoxy resin, 15 parts of polyethylene glycol, 3 parts of TEA catalyst, 8 parts of water and 10 parts of emulsifier respectively according to parts by weight;

[0052] Step 2: Heat polyethylene glycol at 90°C to melt, add modified bisphenol epoxy resin and TEA catalyst, and stir evenly;

[0053] Step 3: Heat the evenly stirred mixture to 115° C., and maintain this temperature for 8 hours to obtain a water-based modified bisphenol epoxy resin;

[0054] Step 4: Add water and an emulsifier to the water-based modified bisphenol epoxy resin, stir and mix to prepare a modified bisphenol epoxy resin emulsion.

[0055] Wherein, the synthesis method of the modified bisphenol epoxy resin is as follows: according to the molar ratio, 1 part of bisphenol A is mixed with 0.15 part of bisphenolic acid, and then 2.35 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com