Preparation method of elastomer-based polypropylene insulating material with high partial discharge tolerance

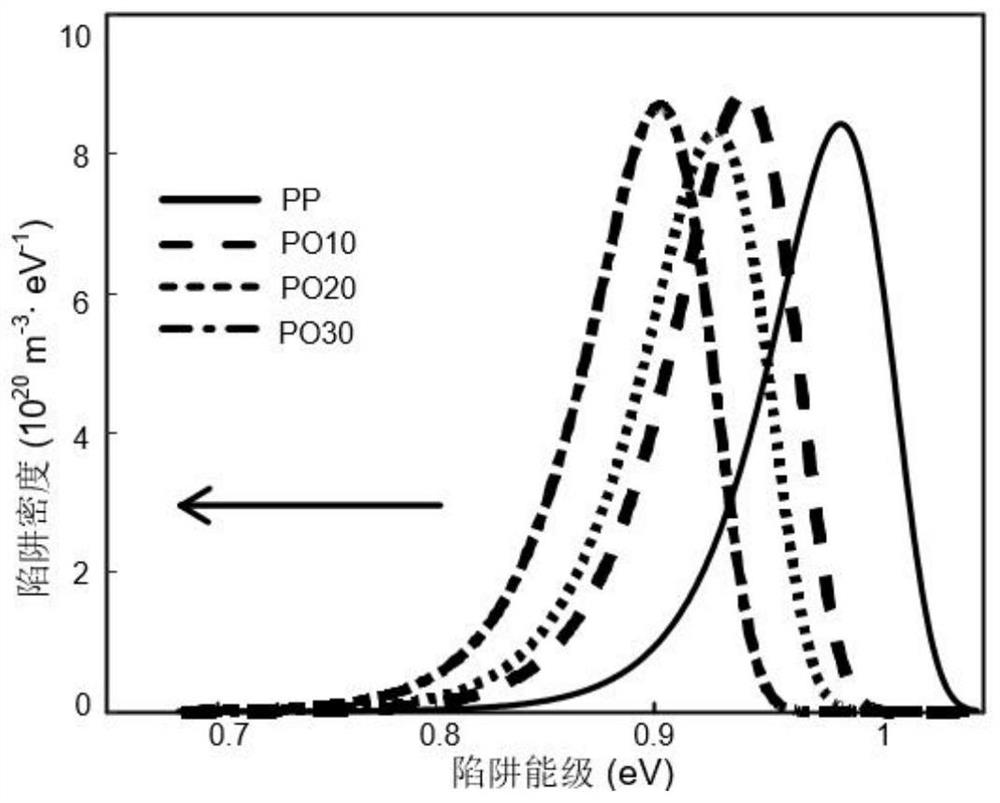

A partial discharge and insulating material technology, which is applied in the field of preparation of high partial discharge tolerance polypropylene insulating materials, can solve the problem that polypropylene insulating materials have low partial discharge tolerance, there is no patent for improving partial discharge tolerance, and Insulation performance of polymer materials, etc., to achieve the effect of good UV radiation resistance, improved partial discharge resistance, and improved partial discharge erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

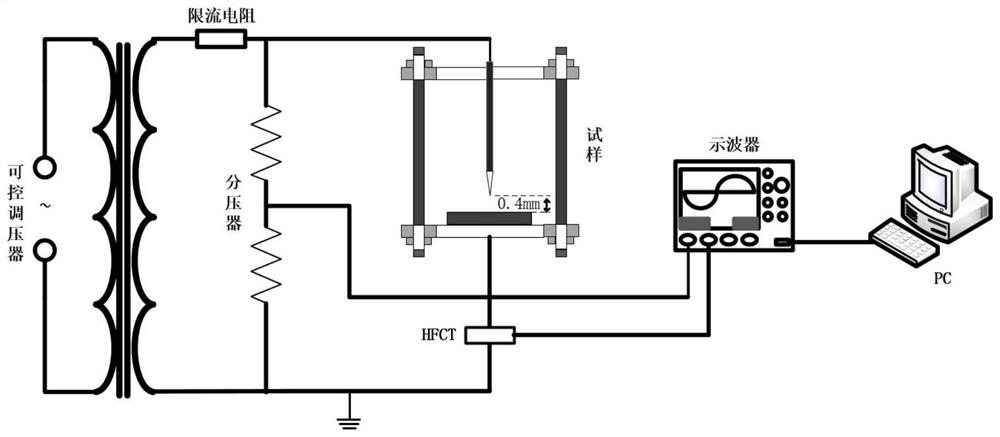

[0023] A method for preparing an elastomer-based high partial discharge tolerance polypropylene insulating material, characterized in that: the steps of the method are:

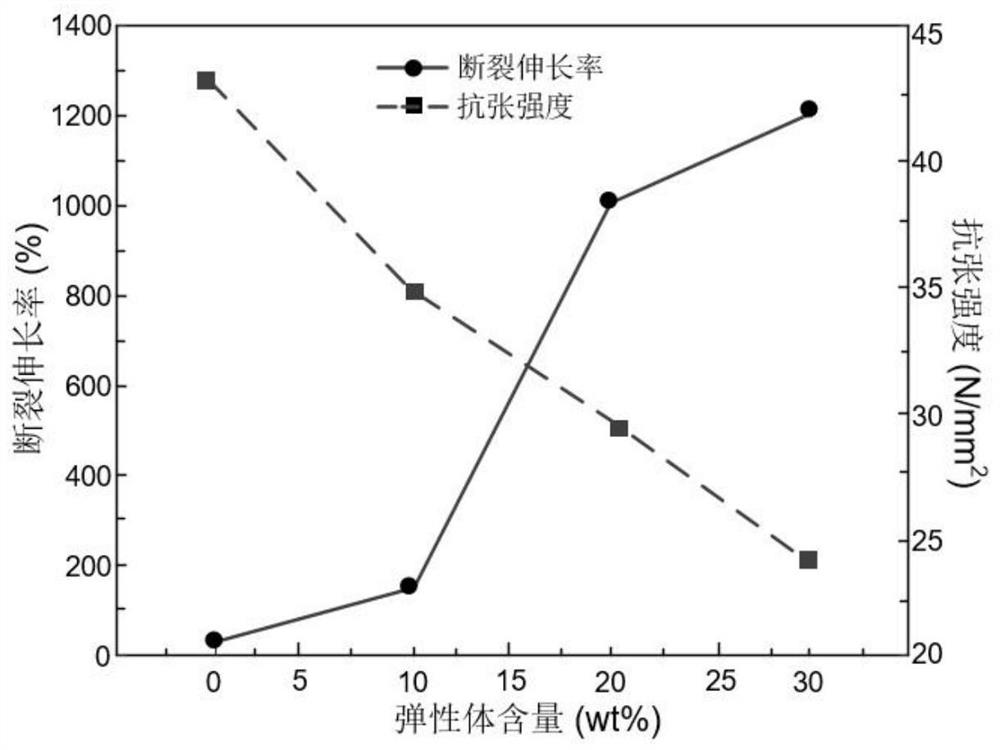

[0024] 1) Select isotactic polypropylene with an isotacticity greater than or equal to 96% as the main material, and octene ethylene elastomer as a filler. The octene ethylene elastomer is copolymerized from octene with a content greater than 50% and ethylene monomer with a content greater than 20%. Forming, using absolute ethanol to clean the main materials and fillers, and putting them into a vacuum drying oven for 24 hours at 40-60°C;

[0025] 2) Mix the octene ethylene elastomer and isotactic polypropylene in an addition amount of 18-22% evenly, and melt and blend them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com