Bimetallic brake drum structure, brake drum shell and manufacturing method thereof

A brake drum, bimetal technology, applied in the direction of brake type, brake components, brake drum, etc., can solve the problem of not using thin steel plates, and achieve the effect of reducing process cost, ensuring structure, and strengthening strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

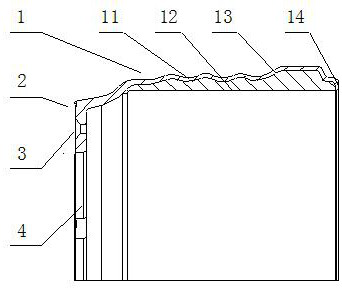

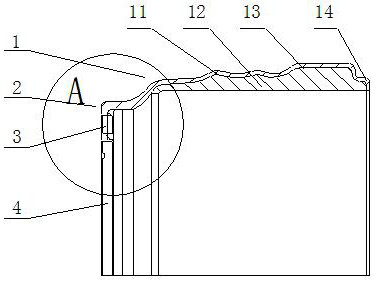

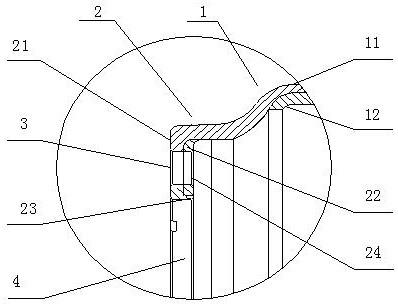

[0042] Embodiment 1: as figure 2 As shown, the bimetallic brake drum of this embodiment has the following structural features. The brake drum is composed of a rim portion 1 and a flange portion 2 . The rim portion 1 is composed of a steel shell layer 11 and a cast iron friction layer 12, the friction layer 12 is arranged inside the shell layer 11, and the two are combined by casting. The flange part 2 is composed of a steel structure layer 21 and a cast iron reinforcement layer 22, and the two are also combined by casting. The shell layer 11 of the rim part 1 and the structural layer 21 of the flange part 2 are an integral structure formed by processing steel materials. Different parts adopt different processing methods, for example, the same steel plate is processed, the shell layer 11 of the rim part 1 is formed by spinning and rolling, and the structural layer 21 of the flange part 2 is formed by stamping.

[0043] The rim part 1 of the present embodiment has the same st...

Embodiment 2

[0059] Such as Figure 10 As shown, the structure of the bimetallic brake drum of the present embodiment is basically the same as that of the embodiment, the difference is that the reinforcement layer of the flange portion is not the cast iron layer 22 combined by casting, but a round steel or other material made separately. The ring plate 221, the ring plate 221 is nested in the annular groove 24 of the flange part 2, the bolt hole 3 is set on the ring plate 221, and is fixedly connected with the structural layer 21 and the automobile wheel hub through the bolt hole 3, and the ring plate 221 increases The deformation resistance of the structural layer 21. It can also serve the purpose of increasing the thickness of the flange part and increasing the strength. The processing technology is simpler, but the effect is somewhat different than that of the embodiment, and it is still possible to realize the purpose of the present invention.

Embodiment 3

[0061] As shown in 11, further simplification is carried out on the basis of embodiment 2 to form embodiment 3. When making the brake drum shell, the flange part 2 is not flanged, and there is no need to form the flanging, but directly in the method. The inner side of the blue part structure layer 21 is directly fixed with bolts to the reinforcement layer steel plate 222, and a corresponding engaging structure can also be set between the reinforcement layer steel plate 222 and the steel structure layer 21 to facilitate the close combination between the two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com