Modified Ppy-MXene composite material as well as preparation method and application thereof

A composite material and modified technology, used in the manufacture of hybrid/electric double layer capacitors, nanotechnology for materials and surface science, hybrid capacitor electrodes, etc., can solve the problem of narrow application temperature range, rate performance and cycle performance to be improved and other problems, to achieve the effect of eliminating self-priming of electrolyte, environmental protection and green preparation process, and simple and efficient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Another embodiment of the present invention provides a method for preparing a modified Ppy-MXene composite material, the steps are as follows:

[0042] Add pyrrole to the MXene dispersion for polymerization to obtain Ppy-MXene composites;

[0043] Prepare the ionic liquid into an ionic liquid microemulsion in water;

[0044] The water-in-ionic liquid microemulsion was mixed with the solution of Ppy-MXene composite material, and the modified Ppy-MXene composite material was obtained by ultrasonic treatment.

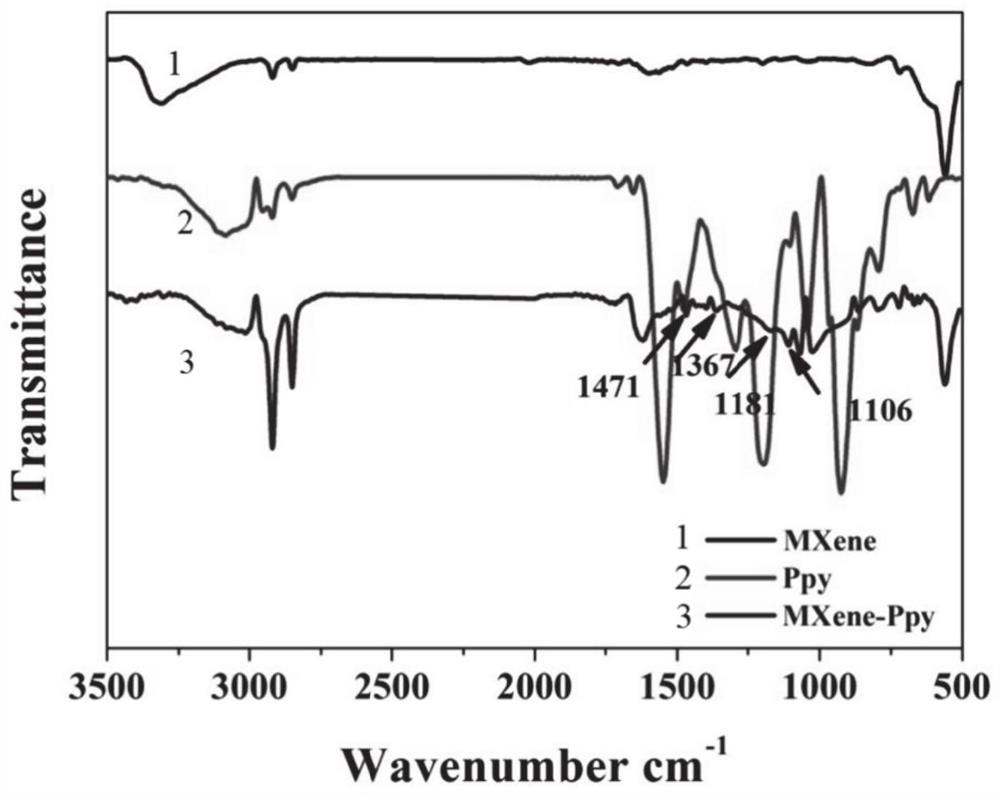

[0045] In the present invention, pyrrole is added to the MXene dispersion liquid for polymerization reaction, so that the polypyrrole can modify the hybrid material constructed by MXenes nanosheets. Ultrasonic treatment can promote the adsorption of microemulsion particles to the surface of the hybrid nanosheets, so that the microemulsion particles can enter between the nanosheets.

[0046] In some examples of this embodiment, pyrrole is added dropwise to the MXen...

Embodiment approach

[0057] The third embodiment of the present invention provides an application of the above-mentioned modified Ppy-MXene composite material in the preparation of supercapacitor electrodes.

[0058] The fourth embodiment of the present invention provides a supercapacitor electrode, including an active material, and the active material is the above-mentioned modified Ppy-MXene composite material.

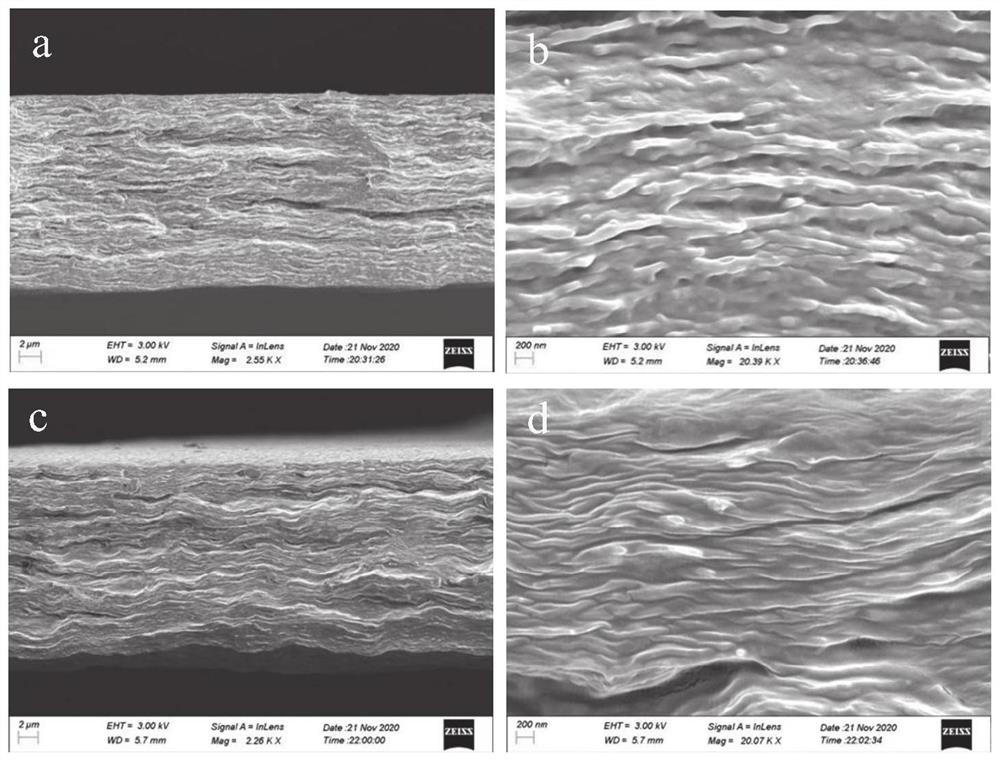

[0059] Specifically, the supercapacitor electrode is a membrane structure. The membrane structure can be prepared from the above-mentioned modified Ppy-MXene composite material.

[0060] A fifth embodiment of the present invention provides a supercapacitor, including the above supercapacitor electrode and an electrolyte, where the electrolyte is an ionic liquid.

[0061] In some embodiments, the ionic liquid is [EMim][TFSI] or [Eim][TFSI].

[0062] In order to enable those skilled in the art to understand the technical solution of the present invention more clearly, the technical solu...

Embodiment 1

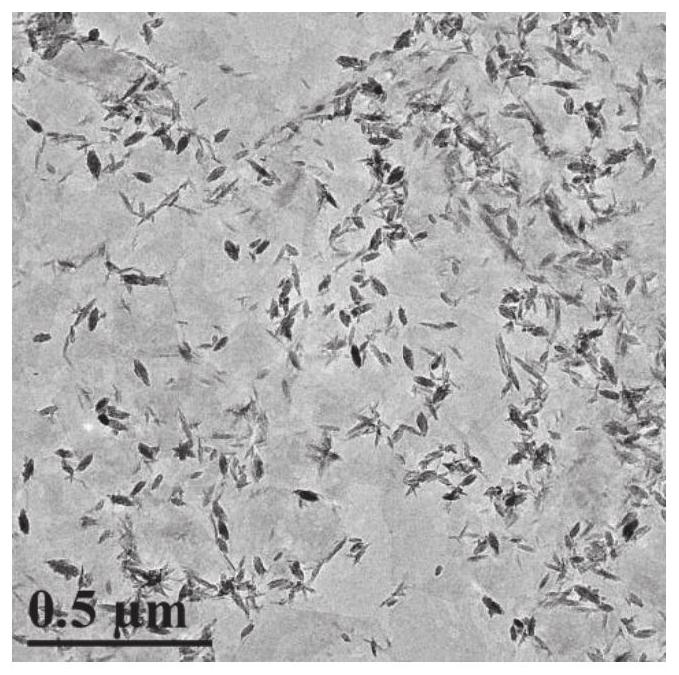

[0064] First synthesis of exfoliated few-layer Ti 3 C 2 T x -MXene nanosheets, using a mixture of hydrochloric acid (HCl) and lithium fluoride (LiF) as etchant, and Ti 3 AlC 2 Raw materials, preparation of multilayer Ti 3 C 2 T x of the dispersion. In an ice-water bath, add 2g LiF to 40mL 9M HCl and stir for 30 minutes, then slowly add 2g Ti in 10 minutes 3 AlC 2 , etch at a constant temperature of 35°C for 24 hours; the multilayer Ti 3 C 2 T x Wash with deionized water, centrifuge until the supernatant pH ≈ 6, pour the supernatant to obtain a precipitate; the obtained multilayer Ti 3 C 2 T x Mixing with 80 mL deionized water to prepare exfoliated few-layer Ti 3 C 2 T x , sonicated for 1 h under Ar gas bubbling; centrifuged at 3500 rpm for 1 h to obtain exfoliated few-layer Ti 3 C 2 T x of black supernatant. Next, 0.1g pyrrole was added to 0.25ml isopropanol, 0.2g pyrrole was added to 0.5ml isopropanol, 0.4g pyrrole was added to 1.0ml isopropanol, and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com