Water cooling structure of axial segmentation inner stator of outer rotor hub motor

A hub motor, axially segmented technology, applied in cooling/ventilation devices, magnetic circuit shape/style/structure, electrical components, etc. Difficult to discharge and other problems, to achieve the effect of simple manufacturing and assembly process, reduce heat generation, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

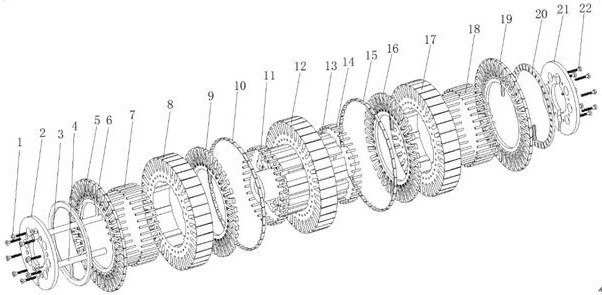

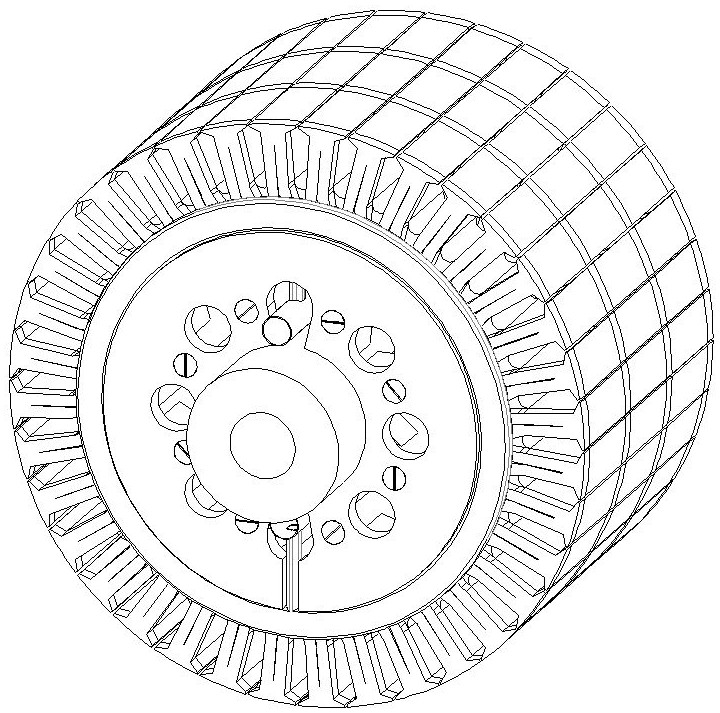

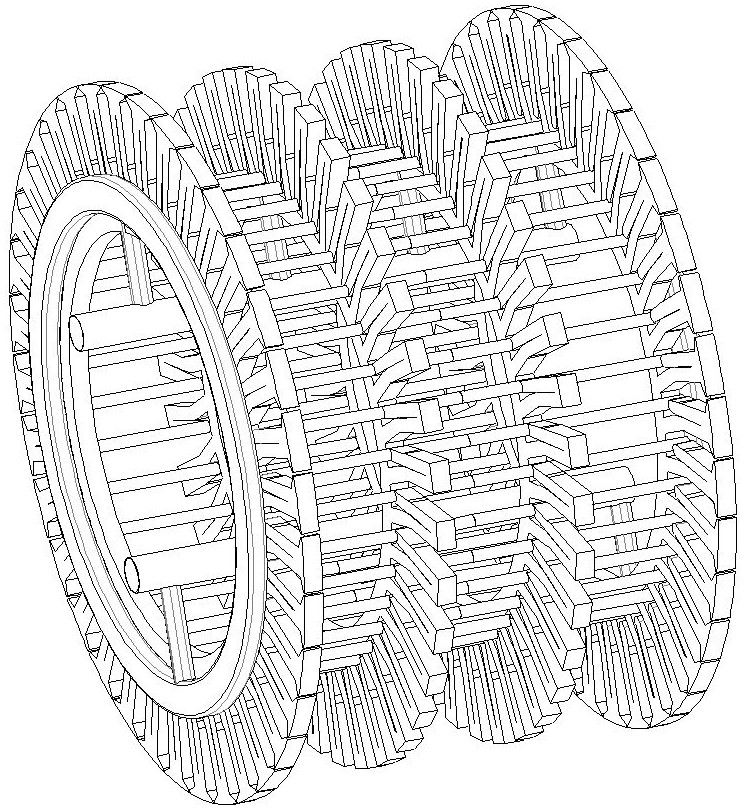

[0027] Such as figure 1As shown, a water-cooled cooling structure for an axially segmented inner stator of an outer rotor hub motor, including: a first set of fastening bolts (1), a second set of fastening bolts (22), and a stator support frame (13); Stator fastening pressure plate one (2), stator fastening pressure plate two (21); main water inlet pipe (4), main water outlet pipe (3); water inlet ring one (5), water inlet ring two (20); Outer cooling plate one (6), outer cooling plate two (19); inner cooling plate one (9), inner cooling plate two (16); pad group one (10), pad group two (15); first Group of cooling through pipes (7), second group of cooling through pipes (18); first group of cooling half through pipes (11), second group of cooling half through pipes (14); block stator one (8), block Stator two (12), block stator three (17)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com